View fulltext

View fulltext

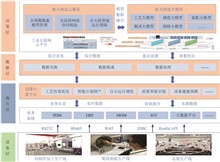

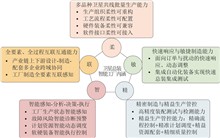

The rapid development of China's aerospace field has led to a significant increase in the variety and volume of aerospace flight vehicles,placing higher demands on the control capabilities of their development and production cycles,costs,and quality.Based on the current development status of aerospace flight vehicle processing and assembly workshops,this paper proposes a development strategy and overall architecture for the intelligent factories tailored to the future multi-variety and large-scale production of aerospace flight vehicles.The key technologies for the intelligent factories are analyzed from the perspectives of dynamic resource organization,human-machine collaborative manufacturing,intelligent quality inspection,and efficient industry chain coordination.By deeply integrating the manufacturing technology with digital and intelligent technologies,this paper aims to provide insights for the construction of intelligent factories tailored to China's aerospace flight vehicle manufacturing.

Data elements serve as a crucial driver for intelligent aerospace manufacturing.This paper proposes a comprehensive data integration framework tailored to the needs of heterogeneous data integration and optimization in the manufacturing of complex aerospace components,including the key techniques such as data acquisition,data processing and modeling,and data analysis and optimization.In response to the spatio-temporal coupling characteristics of multi-source heterogeneous data in the whole process of aerospace manufacturing,a manufacturing data fusion system is proposed to improve the data processing efficiency and integration capabilities such as multi-dimensional index modeling,multi-scale data alignment,and time-scale transformation.Regarding the complex operating laws contained in the aerospace manufacturing process,an algorithm based on the relational network model and graph neural network deconvolution is proposed to enhance the analysis ability of the manufacturing process.Finally,typical application scenarios of data analysis in aerospace intelligent manufacturing are presented,along with case studies that validate the effectiveness of the methods proposed in the paper.

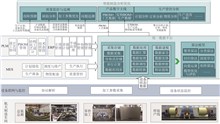

In response to the demands of multi-variety batch,flexible,and intelligent manufacturing,a satellite assembly intelligent factory is proposed,integrating the intelligent manufacturing technology,new generation information technology,and satellite manufacturing.The connotation and system architecture of the satellite assembly intelligent factory are expounded.The key techniques,e.g.,the cross-domain coordination of industrial chains based on the industrial Internet,the flexible intelligent equipment for human-machine collaboration,the decision-making and execution control by artificial intelligence (AI)-assisted processes,and the Intelligent control of factory operation based on digital twins,are put forward.The integrated application of the intelligent satellite assembly factory is verified with practical examples.The results show that the comprehensive production efficiency is significantly improved,indicating that the proposed factory could provide a reference for promoting the transformation of satellite intelligent manufacturing mode.

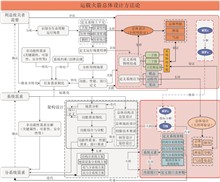

The assembly,integration,and test (AIT) process is an essential part for satellite development.However,the traditional design,techniques,and manufacturing processes are too independent to satisfy the requirements of high-quality and efficient satellite development transformation.In this paper,a digital satellite AIT development model and its manufacturing collaboration scheme are proposed.Aiming at the design-transfer-collection-application stages during the AIT development,a management system is developed and applied by means of the digital techniques such as the definition and integration of the final assembly technical requirements,the structural definition of the AIT process,the standardized definition of the process state,the bidirectional transfer of the design and manufacturing data,and the collection of the manufacture-site data.With the developed system,the online parallel development between the design corporation and the assembly cooperation can be achieved,and the efficiency,quality,and stability of satellite development are improved.The practice of this model provides a practical foundation for the subsequent research on enhancing the global digital planning of AIT and addressing the weakness in the AIT business such as quality feature,comprehensive test,and state management.

The core of the model-based systems engineering (MBSE) method is to establish high-quality integrated models.Model assembly is the foundation for realizing MBSE integrated modeling,since single-point models are difficult to ensure the support and maintenance of the functionality and performance of an entire system.In this paper,based on the single-point MBSE models of launch vehicle systems constructed in recent years,the top-down model assembly methods are investigated.A high-level and extensible top-level model tree is built,and the assembly sequences and methods for various professional MBSE models are clarified.Finally,taking the overall performance,trajectory,and aerodynamics as examples,the construction of an integrated MBSE model for launch vehicles is realized,accelerating the transformation and implementation of MBSE.

In the era of rapid development in the artificial intelligence (AI) technology,every breakthrough in the field of large-scale models captivates global attention.At the dawn of 2025,the DeepSeek R1 model emerges as a dark horse,swiftly becoming the industry’s focal point upon its release due to its high performance,low cost,and open-source nature.Numerous industries,enterprises,and government systems have successively announced integrations with DeepSeek-R1 or its localized deployments,leading to a widespread emergence of application scenarios.Inaerospace research and production,DeepSeek demonstrates significant application potential across various scenarios,including artificial manufacturing,fault diagnosis,and simulation testing.In this paper,the technical advantages and limitations of DeepSeek are investigated,along with its application scenarios,aiming to provide insights for its efficient deployment in aerospace research and production.

With the continuously intensification of global satellite constellation construction,the explosive growth of data and the insufficient processing capability have become the critical bottlenecks hindering the high-quality development of commercial space industry.Although the integration of artificial intelligence and aerospace remote sensing technology has improved the efficiency of remote sensing data interpretation,practical intelligent systems comparable to facial recognition remain underdeveloped.Aerospace remote sensing foundation models have the generalized capabilities in perceived information representation,fusion,interaction,and generation,and are expected to significantly enhance the automation of remote sensing product production and foster new productive forces in the aerospace remote sensing industry.This paper focuses on the technological evolution of aerospace remote sensing foundation models.The current research progresses in aerospace remote sensing foundation models are summarized,and the application prospects of aerospace remote sensing foundation models in the fields such as natural resource monitoring,disaster emergency response,and military intelligence analysis are explored.Additionally,the industrial challenges and development strategies of aerospace remote sensing foundation models are analyzed,particularly regarding data,talent,and computing power.

With the development of manufacturing system,the system composition is becoming more and more complex,and thus the unified management of data is facing challenges such as data content missing,slow update,and inconsistent reference,which may lead to the problems of information coverage and information bias.To cope with the challenges,a knowledge graph (KG) management paradigm in the context of intelligent manufacturing is firstly defined.Then,a top-down and bottom-up approach is proposed to construct the domain KG for multi-source heterogeneous data,and the natural language processing (NLP) technology is used to extract entities and achieve the normalization and standardization of the multi-source heterogeneous data.After that,the results of data processing,graph construction,and information query combined with a large language model are demonstrated through examples.Finally,the directions of further improving management intelligence based on KGs are discussed.

In view of the project proposal for manned lunar exploration,the concept definitions and architecture description methods for the viewpoints and views proposed in the standard specifications,e.g.,ISO42010 and OMG system modeling language (SysML),are expounded.The roles of viewpoints and views in the model-based systems engineering (MBSE) method are elaborated.The main process of constructing model-based analysis views for manned lunar exploration missions are summarized,taking the operation mode of the overall research and demonstration department of manned space engineering to implement the task proposal process as an example.The commercial system modeling tools are used to customize some view templates in the requirement viewpoint,scheme viewpoint,and verification viewpoint of the manned lunar exploration mission analysis process.Finally,the usability and effectiveness of the proposed view customized method are verified through the systematic modeling of the mission scheme.

In view of the multi-disciplinary collaborative design complexity of radar system and the difficulty in ensuring the consistency management of technical states,a forward top-down collaborative design idea based on the bill of materials (BOM) structure is proposed.The model requirements are decomposed based on the task orientation,and the design process is analyzed based on a model-based systems engineering (MBSE) radar virtual prototype.Moreover,an idea for constructing the framework of a radar system collaborative design application platform is put forward,so as to realize the task coordination,driving,and closed-loop design iteration between the overall system and subsystems and subsystems.Finally,a radar system is taken as an example to demonstrate the rationality of the forward design process and modeling method for radar digital prototypes.

In the face of the increasingly complex new situation of on-orbit operation,maintenance,and fault protection of spacecraft,a method for the health status management and prediction of a power-source system is proposed,in view of the on-orbit maintenance practice of the space power-source system and the new requirements for improving the on-orbit maintenance efficiency of the power-source system.The working state of the power-source system is modeled,the varying trends of the key characteristic parameters are analyzed,and a space power-source health status prediction system is constructed.The system adopts a four-layer technical architecture including the data processing layer,the system modeling layer,the data analysis layer,and the application service layer.It has functions such as telemetry data preprocessing,system modeling,data mining analysis,and comprehensive health status evaluation,and can conduct timely,automatic,and effective monitoring and evaluation for the health status of a space power-source system.

In response to the challenges of predicting bearing limit of composite-bolted joints under the coupling effects of multi-source assembly factors, as well as the low efficiency of traditional numerical simulations,this paper proposes a rapid prediction method for the bearing limit based on the Vision Transformer (VIT) framework. By integrating the geometric deformation parameters and physical performance parameters during the assembly process,a nonlinear mapping model between the multi-source assembly parameter space and bearing limit is established. First,the geometric and performance parameters of the composite-bolted joint assembly process are analyzed and modeled. Then,an innovative CBJ-VIT deep learning network based on the VIT architecture is developed,utilizing a multi-head self-attention mechanism to achieve the feature fusion of multimodal assembly data. Finally,case studies are conducted with aerospace thin-walled composite-bolted assemblies for validation. The experimental results indicate that the predicted results from the CBJ-VIT model align closely with the finite element analysis results,reducing the time required for a single prediction from the traditional numerical simulation time of 12 h to just 8.1 s. In both qualitative and quantitative evaluations,the model shows an 85.02% improvement in the prediction accuracy compared with traditional non-image data processing methods and a 76.24% accuracy increase compared with non-VIT architecture models.

To address the issue of fatigue crack propagation in the welded structures of rocket storage tanks,a rapid prediction method for the structural fatigue life based on the Kriging model is proposed.A scaled finite element model is established for such a tank,and joint simulations with the ABAQUS and FRANC3D software are conducted to study the crack propagation behavior of the initial cracks under different regions,stress ratios,and inclination angles.The results show that the crack propagation rate in the weld zone is higher than those in the heat-affected zone and base material zone.The crack propagation rate in the longitudinal weld zone is higher than that in the circumferential weld zone.The crack propagation rate in the longitudinal weld zone increases as the stress ratio decreases,and the fatigue life is the longest when the initial inclination angle is 0°.A high-accuracy Kriging model is developed,taking the initial crack location in the longitudinal weld zone,the inclination angle,and the stress ratio as the inputs and the fatigue crack propagation life as the output.The model enables rapid prediction for the crack propagation life in the welded structure of a storage tank.The results show that compared with the extended finite element method,the proposed method can shorten the life prediction time by more than 10 times while ensuring low calculation errors.

In space missions,the separation performance of docking mechanisms directly affects the stability and reliability of the missions.In this paper,a digital twin experimental platform for space docking mechanisms is established based on the digital twin technology,along with the fusion method of data and knowledge.The Bayesian optimization algorithm is used to enhance the predictive model’s ability to learn the coupling relationship between the component degradation and separation performance,and a high-precision separation performance prediction model is established.The shapley additive explanations (SHAP) interpretability analysis is adopted to reveal the impacts of key components on the separation performance.The experimental results demonstrate that the platform improves the testing efficiency and reliability through real-time simulation,dynamic monitoring,and separation performance prediction,supporting the optimization and safety assurance of docking missions.

Online anomaly detection is a key technology to ensure the normal operation of rocket servo systems.However,most current methods do not consider the concept drift problem that exists when models are deployed and applied,which in turn affects the detection accuracy.Therefore,based on the generative recurrent networks,this paper proposes an online anomaly detection algorithm for servo systems.First,a deep recurrent neural network is proposed to model the input-output relationship of a servo system.The network introduces multi-layer memory cells and jump connections to improve its capability to fit the multi-scale spatio-temporal dependent properties of the data.Second,to mitigate the conceptual drift problem,online learning is introduced to make the model capable of continuous learning,but it also introduces the problem of catastrophic forgetting.Finally,to mitigate the catastrophic forgetting problem,a generative network is proposed to generate the retrospective data containing information about the overall distribution of historical data.It allows the model to learn new data distributions while avoiding forgetting information about the historical data distributions.Based on the actual rocket servo system operation data,the ablation experiments and comparative experiments are carried out.The results show that the proposed algorithm can effectively address the aforementioned problems and achieve good anomaly detection results.

Setting a transverse hydrogen jet in the induction zone is an effective active control scheme to implement the controllable and fast initiation of an oblique detonation wave (ODW) under high altitude flight conditions.In this paper,the flow characteristics of the ODW induced by a transverse hydrogen jet and the effects of the jet dynamic pressure ratio and jet angle are studied by solving the two-dimensional reaction Euler equations.The results show that the accelerated initiation of an ODW can be implemented by setting a transverse hydrogen jet in the induction zone.The jet-induced ODW has two initiation patterns,i.e.,strong coupling and weak coupling.In addition,the height of the ODW at the exit of the combustor is proportional to the jet dynamic pressure ratio and jet angle,and the active control of the ODW can be implemented by changing the jet dynamic pressure ratio and jet angle.Therefore,with proper jet dynamic pressure ratio and jet angle,the stable operation of ODW engine can be achieved.

To address the needs for the rapid modal frequency prediction and structural fault localization for slender body aircraft,an efficient method combining engineering prior knowledge,artificial neural networks,and parameter identification is proposed.Based on the sample design,the one-dimensional mass-spring-stiffness beam model is used to calculate the low-order modal frequencies of the structural dynamics of a slender body aircraft.By leveraging the rapid mapping capability of neural networks,the global mass and stiffness of the aircraft are efficiently identified based on the modal frequencies achieved.In engineering practice,the nose cone mass anomalies are accurately located,and the quality error does not exceed 3.13%.

To address the challenge of feature-level fusion in sequence image-based space target recognition,this paper proposes a method combining convolutional neural networks (CNNs) and recurrent neural networks (RNNs) with model improvements.In view of the problem of how to use a single image as a sequence feature input,the CNN is modified,in which the feature maps are used as the sequential inputs.In view of the problem of how the sequence features map to the target categories,the long short-term memory (LSTM) network is modified,in which the output layer is enhanced with a new fully connected layer to predict the target categories.Training with the Gaussian noise levels of 0.001~0.006 and testing at 0.007~0.010 achieve a mean average precision (mAP) improvement from 90.7% to 99.16%.Under different postural conditions,the mAP reaches 94.71%.The model has only 283.0 M parameters,effectively addressing the limitations of result-level fusion in existing methods.

The prediction accuracy of orbit-controlled jet is the key technology of high-speed interception weapons.Currently,there are scarce studies on the jet interaction at high altitudes and large Mach numbers,and the law of influence of various physical effects on the jet interaction during high-speed flight in this airspace is not systematic enough.By solving the three-dimensional chemical non-equilibrium Navier-Stokes equation with slip boundary conditions,the influence of the high-temperature thermochemical non-equilibrium effect,gas secondary combustion effect,and rarefied gas effect on the orbit-controlled jet interaction is analyzed,and the influence of various physical effects on the aerodynamic characteristics of the orbit-controlled jet interaction under different flow conditions is obtained.The results indicate that the high-temperature dissociation reaction of the incoming air and gas components is the main factor accounting for the difference between the cold air and hot gas at high altitudes and large Mach numbers,and the influence degree decreases when the altitude increases while increases when the Mach number increases.The influence of the rarefied gas effect on the interaction aerodynamic force/moment of the overall jet is minor.

To investigate and verify the accuracy,robustness,and computational efficiency of the gas kinetic method in dealing with hypersonic vehicles,numerical simulation is conducted by means of a unified gas kinetics scheme (UGKS) and a gas kinetics inviscid flux (KIF) scheme developed based on the Stanford University Unstructured (SU2) open-source platform (SU2-KIF).The simulation focuses on the steady flow around the HTV-2 typical hypersonic vehicle under the conditions of an incoming Mach number ranging from 6 to 12,a flight altitude ranging from 30 km to 70 km,and a flight angle of attack ranging from 5° to 20°.The distributions of heat flow and pressure on the vehicle surface,as well as the aerodynamic force and moment coefficients,are statistically analyzed,and the changes in the aerodynamic force and aerothermal effects during the flight process are investigated.