View fulltext

View fulltext

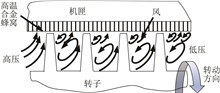

Micron-scale superalloy honeycomb cores (MSSHCs) have the advantages such as light weight,high temperature resistance,and excellent sealing,and have been used as the core material of key components in new generation aero-engines and hypersonic aircrafts.An MSSHC is extremely small,with an area of only 1/10 of a common superalloy honeycomb core.Therefore,it has the difficult machining characteristics of superalloy and thin-wall structure at the same time.This makes MSSHCs extremely prone to the defects such as burrs,core deformation,and tearing during machining.To solve the above problems,the ultrasonic assisted machining technology for MSSHCs is designed.The cutting angles of single and double walls of MSSHCs are investigated according to the geometric relationship between the workpiece and tool during side machining.Based on the grinding/milling experiment,the mechanisms of ultrasonic grinding/milling of MSSHCs and defect formation are revealed.The results show that the cutting angles of single and double honeycomb walls are 60° and 0°,respectively.Under the same machining conditions,compared with the grinding wheel,the designed milling cutter has smaller cutting force and shorter burr length.Ultrasonic vibration is beneficial to crack propagation,reducing the grinding force,burr length,core deformation,and tearing defects.The above investigations provide a theoretical basis for the high efficiency and low damage machining of MSSHCs.

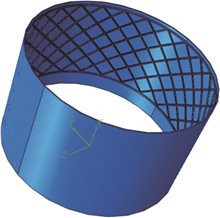

Aiming at the problems of material thickening and long manufacturing process caused by existing cylinder splicing manufacturing methods for rocket tanks,a new process method of flow spinning forming for cylinders with bars is proposed.The coordination control mechanism of forming process and the precise forming control method for components are proved,and the prototype process and devices for forming cylinders with bars are developed.It is found that the multi-wheel spinning has more constraint points in the axial material,which increases the stiffness of the operating point of the spinning wheel,better inhibits the expansion phenomenon,and improves the uniform filling of the axial inner ribs of the grid bar.The average filling degree of three-turn wheel is improved by 4.27% compared with that of two-turn wheel.In this paper,the simplified aluminum alloy with the outer diameter of ϕ865 mm and the rib aspect ratio of 1∶1 is prepared by experiment for the first time,and a ϕ3 350 mm cylinder with inner cross bars is developed,which provides technical basis and theoretical basis for future rocket manufacturing.

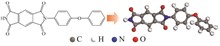

Laser-induced graphene has been widely used in the fields such as microelectronics,energy storage devices,and flexible wearable devices due to its convenient preparation,tunable physicochemical properties,and strong compatibility.The acquisition of high-quality laser-induced graphene is an important prerequisite for further promoting its application.This paper focuses on the carbonization process of laser-induced graphene.A molecular dynamics model based on the ReaxFF reactive force field is built.The carbonization process is analyzed by adjusting the control parameters of polyimide (PI) pyrolysis.The growth mechanism of graphene clusters is investigated based on the molecular configuration evolution and crystalline characteristics analysis.The simulation results indicate that increasing the reaction temperature or prolonging the reaction time helps increase the number of hexagonal rings in the products.Based on the simulation conclusions, high laser power and low scanning speed are used to prepare laser-induced graphene (LIG) supercapacitors,and favorable rate performance (70% initial capacity is maintained at a scanning rate of 500 mV·s-1) and low equivalent series resistance (52 Ω) are achieved.

Carbon fiber reinforced resin matrix composites have been widely used in aerospace,transportation,and new energy fields due to their excellent properties such as high specific strength,high specific modulus,corrosion resistance,heat resistance,and thermal stability.At present,the constitutive models for carbon fiber composites are generally obtained by experimental methods or finite element methods,but the analytical modeling is still challenging due to their complex microstructures and multiaxial loading failure mechanisms.Therefore,a systematic review of the relevant research progresses reported in the literature on the analytical modeling of constitutive models for carbon fiber reinforced resin matrix composites is presented.First,the current status of research on the construction of constitutive models for carbon fiber reinforced resin matrix composites is outlined.Second,starting from the constitutive models for unidirectional carbon fiber composites,the relationships between the stress and strain of the carbon fiber and the resin matrix are analyzed separately,and the corresponding calculation methods of the constitutive models for the composites are described.Third,the mechanical structures of three-dimensional braiding composites are analyzed,and the constitutive models for unidirectional carbon fiber composites is extended to develop the progressive damage constitutive models for multi-directional carbon fiber composites.Finally,the development trends of the constitutive models for carbon fiber reinforced resin matrix composites is put forward.

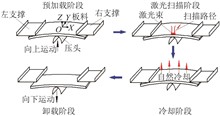

Pre-stress laser bending is a new method for the plastic bending of high strength aluminium alloy panels with no damage and high precision.In order to control the bending deformation reasonably,the elastic-plastic deformation behavior of the forming aluminium alloy panels should be revealed.In this paper,the elastic-plastic deformation behavior of a being bent high strength aluminium alloy panel is investigated with the finite element simulation method along with the strain energy theory of elastic-plastic mechanics.It is shown that during the laser scanning process,the generated plastic strain energy is derived from the transformation of both the elastic strain energy induced by pre-load and the laser thermal energy.With the increase in the pre-load,the plastic strain energy increases exponentially.With the increase in the laser energy,the plastic strain energy increases linearly.The increase in the plastic strain energy mentioned above is mainly due to the greater conversion of elastic strain energy.Based on the analysis results,the regulation and verification for the elastic-plastic deformation of the forming high strength aluminium alloy panel are carried out,which indicates that the high efficient and high precision elastic-plastic deformation control of the high strength aluminium alloy curved integral panel is achieved.

In order to solve the problem that the single performance of homogeneous ceramic materials and structures limits their application,an additive manufacturing technology for the photocuring/spray deposition composite process is proposed from the perspective of the working mechanism and integration of polymorphic modules,including the whole machine,worktable,multi-axis motion module,laser and mirror module,spray module,sensing and valve module,and process module.A prototype of photocuring/spray deposition multi-material ceramic additive continuous forming equipment is built,and the multi-system collaborative motion process of “coating+solidification+spray+solidification” is studied to optimize the stability of multi-module motion.The combination logic of the multi-process composite technology is studied,and the multi-material CeraMulti Slicer software and CeraMulti Driver configuration software are developed.A collaborative motion mechanism and a high-precision integrated control system are developed for the photopolymerization forming motion mechanism and spray deposition module.The integrated preparation of forming control for multi-material ceramic parts is explored.The results indicate that this technology can prepare multi-material ceramic samples with high accuracy,good interface bonding,and no defects.

In response to the disadvantages of magnesium alloy corrosion resistance,based on the storage period and inter process corrosion issues of Mg-Gd-Y rare earth magnesium alloys,a silanization surface treatment technology is developed to improve the corrosion resistance of magnesium alloys.On the basis of traditional single silane films,composite silane films and dual-layer silane films composed of multiple silane composites are developed,and their film layer structures are explained.Electrochemical and immersion tests are conducted for corrosion resistance verification.The results show that compared with a single silane film,the self-corrosion current densities of the composite and dual-layer silane films are decreased by an order of magnitude.The corrosion time in the NaCl solution with a mass fraction of 3.5% increases from 24 h to 168 h.

The thermal vacuum accelerated life tests of space motion mechanisms at home and abroad are mainly focused on the components,which cannot fully reflect the long life performance of the whole machine.In this paper,a thermal vacuum life test scheme is designed for the long-life filter wheel mechanism of an optical survey telescope in space environment.The working conditions and complex environmental factors of the filter wheel mechanism during space operations are fully considered,and the vacuum accelerated life test of the filter wheel mechanism is carried out to verify whether the solid lubrication bearing assembly,the transmission pair solid lubrication design,and the performance of the whole machine can meet the requirements of on-orbit life.According to the life requirement of the filter wheel rotating 8×104 times in orbit,a specific test scheme is designed,and a thermal vacuum space environment test platform is built.The test results show that the life test runs normally and the cumulative rotation times is 1.6×105.After the test,the bearing friction torque and starting torque are re-measured,and then the bearing assembly is dissected.The results show that the bearing friction torque and starting torque are the same as those before the test,and the bearing lubrication is good.After the test,the solid lubrication of the worm gear pair is analyzed by high power microscope.The results show that the worm gear pair base is covered by the lubrication film and the lubrication state is in good condition.After the test,the performance test of the filter wheel mechanism is carried out,and the test results meet the performance indices.The results of the accelerated thermal vacuum life test can verify that the life of the filter wheel can meet the requirements of the long-life mission in orbit,which can also provide a basis for the long-life design of other space motion mechanisms and provide a reference for the life tests of other mechanisms.

With the development and initial use of reusable spacecraft, online monitoring the structural responses, understanding the structural health status in real time, and effectively identifying the structural damage state have become important ways for reusable spacecraft to ensure its economy efficiency. In this paper, a multi-damage self-identification method is proposed for the online assessment of composite structural damages in reusable spacecraft. The method first achieves the high-precision imaging of multiple damages in composite structures based on guided waves. Then, a probabilistic mixture model is used to cluster the damaged pixels, where the pixel values with high damage probability in the monitoring area are matched with the Gaussian model components. This allows the damage status of the structure to be automatically evaluated based on the number, mean value, and covariance of the Gaussian model components. Finally, experiments are carried out to verify the proposed method. The results show that the method can effectively identify the number, locations, and directions of the damages.

The flexure hinge,as a critical component of compliant mechanisms,has garnered widespread attention from researchers worldwide.To explore the feasibility of applying the additive manufacturing technology in the design of flexure hinges,a cross-spring flexure hinge for additive manufacturing processes is designed.First,an equivalent stiffness model of the crossed-spring flexure hinge is established.Second,three key design parameters,i.e.,the spring thickness t,the hole dimensions a and b,and the crossing angle α,are selected,and the selective laser melting (SLM) technique is used to fabricate a set of hinge prototypes.Third,the fabricated prototypes are analyzed theoretically,simulated by the finite element method,and tested by a visual testing platform.The results demonstrate good consistency among the theoretical,simulation,and experimental stiffness values,verifying the validity of the proposed model.Finally,the flexible hinge structure is optimized by introducing reeds at the contact points between the springs and the matrix and employing springs with non-uniform thicknesses,which enhances the manufacturing stability and improves the transmission performance of the hinge.

In view of the structural lightweight requirement of slewing support mechanisms for aircrafts,the optimization design and additive manufacturing of slewing support mechanisms for aircrafts are studied,considering the process constraints.The structure is divided into design domains based on the part functions,the key load-bearing parts are topologically optimized,and the shell surfaces are parameterized.Then,the model for additive manufacturing is modified according to the overhang angles and size constraints.Finally,the modified model is verified by the finite element simulation.The results show that after additive manufacturing printing and post-processing,the optimized part achieves a 21.74% weight reduction,meeting the design requirement.

In view of the problems of low detection efficiency, high work intensity, and high error detection rate in the detection methods, e.g., artificial visual vision and stalk measurement, for the automatic riveting quality detection of launch vehicle capsules, an online detection method for the automatic riveting quality of launch vehicle capsules based on the machine visual system is proposed. With the method, launch vehicle capsules can be detected with high efficiency and high quality while being automatically drilled and riveted. The mapping relationship of a rivet digital image to the physical space is established, and high-quality rivet pier head images are obtained by the angle correction algorithm based on the perspective transformation. The pier head edges and surface images are used to obtain the key size parameters and surface defect information of the pier head, and then the riveting quality is determined. The results of the process test show that the average detection speed of this method is up to 0.92 s/rivet, which can be completed synchronously with the riveting process, and greatly improves the efficiency of riveting quality detection. The detection rate of unqualified rivets is 100%, and the detection accuracy is 99.8%, which significantly reduces the false detection and missed detection rate.

The automatic detection technology for digital radiographic images of launch vehicle welds primarily involves the classification of digital radiographic images of launch vehicle welds. However, the actual production process yields an enormous volume of images, and annotating the entire dataset would entail a considerable waste of manpower and resources. Considering that prior supervisory information can enhance the precision of target extraction and that removing the background from images can improve classification accuracy, this paper proposes a Semi-supervised Target Feature Extraction algorithm with Laplacian Eigenmaps (LE) Regularization based on Robust Principal Component Analysis (RPCA), termed SSRLE. On the premise of ensuring the global structure of the data, the local structure of the data is guaranteed by adding the LE regularization of the weight matrix of the adaptive neighborhood graphs, and the influence of the nearest neighbor value k in the classical LE algorithm is excluded. Under the influence of prior information, the target and background are separated effectively. The linear classifier is trained with the target data and supervision information. With the manifold smoothing hypothesis, the trained linear classifier can predict unlabeled data, resulting in improved classification results. Finally, experiments are carried out, and the classification effects of different semi-supervised algorithms are compared. The results show that the proposed method is valid, and is superior to other methods.

With the increasingly issues of energy crisis and environmental pollution,technologies with energy conservation and consumption reduction functions have become an urgent demand in the aerospace field.Surface micro-textures have been widely applied in the aerospace field,owing to their excellent functional properties such as friction reduction and drag reduction.In this paper,the functional mechanisms of surface micro-textures and their typical applications in the aerospace field are thoroughly explicated from the aspects such as friction reduction,drag reduction,thermal management,anti-icing,and self-cleaning.The challenges and solutions of surface micro-texture applications in the aerospace field are summarized,and the future development directions are proposed.

In response to the resource scarcity issues in space manufacturing,two technologies for recycling three-dimensional (3D) printed continuous fiber reinforced composites are proposed.The reverse melting drawing method is adopted to recycle the carbon fiber reinforced polyether ether ketone (CF/PEEK) composites.An innovative overcooling 3D printing process for polyphenylene sulfide (PPS) self-reinforced composites is developed,enabling the manufacturing and recycling of self-reinforced composites.The evolution laws of the microstructure and mechanical properties of the composites before and after recycling are studied.The recycled prepreg filaments are reprinted to obtain CF/PEEK samples,with flexural strength and modulus improved by 4.8% and 50.8%,respectively,compared with the original ones.The flexural strain of the samples printed by the recycled PPS self-reinforced composites is increased by 13.8% compared with that printed by the original PPS composites,and the toughness is significantly enhanced,achieving non-degradable recycling.Overall,a full lifecycle recycling and reuse strategy for 3D printed composites for space manufacturing is explored,providing support for the future development of space manufacturing.

Aerospace engineering development is a complex system engineering project.It involves many links with close combination,and any link problems may bring irreversible losses to the project development.With the high-density development and launch situation of aerospace engineering,the number of aerospace product tasks is increasing year by year,and the quality problems also occur frequently.This shows that the risk identification is not comprehensive,the risk control is not in place,and the risk management is not standard.In this paper,the quality situation of aerospace development is discussed,and the problems of risk identification are pointed out.The relevant standards used at present are summarized,which provides tools and means for the technical risk analysis and control of the model.Finally,taking Fengyun-4 (FY-4) microwave satellite as an example,the risk analysis,the identification,and the control process and effect are given,providing reference for other models.

Inductive pulsed plasma thruster (IPPT) are promising candidates for future space nuclear propulsion.Focusing on the high efficiency energy deposition and conversion technology in IPPTs,this paper carries out a literature review from three aspects:the basic working principle,the thruster performance optimization theory,and the thruster magnetic penetration characteristics.First,the performance and technical characteristics of various types of IPPTs are compared and analyzed.Considering the performance differences of thrusters,the roles,limitations,and interrelationships of different performance optimization theories,e.g.,Lovberg criterion,dynamic matching theory,and critical specific energy principle,are summarized.Then,by comparing the magnetic field distributions in different types of thrusters,the influence of magnetic field permeability characteristics on the energy deposition and conversion of thrusters is clarified,and the main methods,important conclusions,and limitations of the magnetic field permeability characteristics used in experimental and numerical studies are discussed.

The thermal protection of hypersonic aircrafts in flight are under the threat of severe aerodynamic thermal problems.The active thermal protection technology through mass injections can effectively reduce the skin-friction and heat flux on the wall,and thus has become a hot topic in thermal protection research.However,the laws and differences in the effects of injection gases on the high-temperature hypersonic laminar/turbulent boundary layer flow are still unclear,and this is an urgent aerodynamic problem to be solved in active thermal protection design.This paper selects a two-dimensional flat model and adopts the shear stress transport (SST) model to conduct numerical simulation research on the heat flux and skin-friction reduction considering injection gases.The effects of three injection gases,i.e.,water vapor,carbon dioxide,and pyrolysis gas,on the high-temperature hypersonic laminar/turbulent flow are analyzed.The results show that under the pyrolysis gas injection,there are significant differences in the velocity and temperature distributions of the laminar/turbulent shock layer.Compared with no injection,the three gases all effectively reduce the velocity and temperature gradient at the turbulent boundary layer,and then reduce the skin-friction and heat flux on the wall.Compared with the other two gases,the pyrolysis gas has the most significant effects on the skin-friction and heat flux reduction.The research results also indicate that the three gases significantly increase the Reynolds stress and intensify the turbulent fluctuation.

Synchronous time reference is the key basis of cluster cooperative control.In view of the reduced convergence accuracy and speed of cluster network time synchronization caused by the absence of external precise clock source and the delay of internal communication,a clock synchronization algorithm combining the motion model and state estimation is proposed.In this algorithm,a linear regression model conforming to the clock model is constructed,and the clock compensation parameters are estimated with the pseudo-measurement data.In the self-constructed and maintained cluster unified time base,a time registration algorithm based on two-step weighted fusion is used to achieve the asynchronous measurement data fusion of the target.The simulation results show that the clock synchronization algorithm based on the motion model and state estimation has fast convergence and high clock synchronization accuracy,which can provide a unified time reference for subsequent data fusion,and the time registration algorithm based on two-step weighted fusion has higher accuracy than the one-step Kalman prediction method.

The complex electromagnetic environment generated by the deployment of multiple signal sources and radar countermeasures in modern cognitive electronic surveillance methods severely limits the degree of prior information available for effective target identification.In this paper,a dual-view collaborative clustering method based on radar signals is proposed to classify radiation sources,especially in dual-view scenarios.The proposed method iteratively performs unsupervised clustering,cluster label transfer,and dimension reduction through linear discriminant analyses,by which the differences between the clustering results obtained from dual-view scenarios can be distinguished,enabling radiation signal ranking in non-cooperative environments.The experimental results demonstrate that the proposed method can effectively leverage the differences between the basic signal features and intra-pulse characteristics,and enhance the accuracy of cluster-based radiation source sorting.Therefore,the sorting ability of the proposed method has very high practical value.