The flexibly and precisely control of wavefronts of electromagnetic waves has always been a hot issue, and the emergence of metasurfaces has provided a platform to solve this problem, but their design and optimization remain challenging. In this work, the research team combined diffraction metagratings with asymmetric scattering patterns to achieve an angle-suppressed effect, which breaks this symmetry so that the energy is no longer equally distributed into positive and negative diffraction orders. The asymmetric scattering metagrating with different diffraction orders were designed and combined in a periodic circular array to form a metalens, which works to generate bending angles of wavefront manipulation for focusing at different radial positions. Well, in the terahertz band, it is challenging to design a focusing metalens with the sub-wavelength scale focal spot and long DOF, and simultaneously remain high efficiencies.

To address these limitations, Professor Jia Shi's team from Tiangong University, propose two design and optimization methods for metagrating-based metalenses based on the highest manipulation efficiency and highest diffraction efficiency, respectively. Both proposed methods can realize the design of focusing metalenses with excellent performance, they can both obtain a sub-wavelength scale focal spot with long DOF, simultaneously with high efficiencies. Relevant research results were recently published in Photonics Research, Volume 13, Issue 2, 2025. [Jia Shi, Guanlong Wang, Longhuang Tang, Xiang Wang, Shaona Wang, Cuijuan Guo, Hua Bai, Pingjuan Niu, Jianquan Yao, Jidong Weng, "High-efficiency focusing metalens based on metagrating arrays," Photonics Res. 13, 351 (2025)]

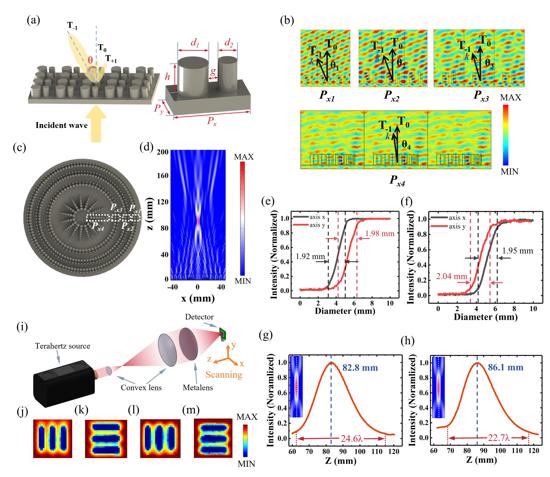

The research team demonstrates two metalenses operating at 0.14 THz with numerical apertures of 0.434, which are designed by these two methods. Each of the metalenses includes four periodic circular metagrating arrays, arranged from inside to outside. The incident terahertz wave transmitted through the metagrating is split into different diffraction orders, the diffraction efficiency is defined as the amount of power deflected into a particular diffraction order divided by the incident power. The manipulation efficiency is defined as the amount of power deflected into a particular diffraction order divided by the total transmission power which transmitted through the metagrating. The metagrating array is as shown in Fig. 1(a), where h and dn are the height and diameter of the cylinders, g is the gap between the adjacent cylinders in the unit cell. Px is the diffraction period which controls the diffraction order and bending angle of electromagnetic wave. By the design of the diffraction period, the unit cells are designed to deflect the incident terahertz waves to 24.23°, 20.56°, 16.04° and 7.48°, respectively, so that all the unit cells can bend the incident terahertz wave to the desired focal spot to achieve high-efficiency focusing. Accordingly, the diffraction periods are 5.22 mm, 6.10 mm, 7.76 mm, and 16.47 mm. Fig. 1(b) shows the simulated electric field distributions for metagrating array with diffraction periods. The geometrical structural design is optimized with these two optimization methods for each unit cell in parameters space. With optimizing structural design of the unit cells, they are arranged and bend circumferentially to form two separate metalenses, respectively. The metalens with the highest manipulation efficiency is used as a demonstration, the schematic diagram of the metalens is as shown in Fig. 1(c), and the simulated electric field distribution of the metalens with the highest manipulation efficiency is as shown in Fig. 1(d).

Most of the existing terahertz metalenses are fabricated with Si/SiO2, but they often suffer from large losses, complicated and costly steps, and long fabrication time. The research team has been seeking fabrication materials with low losses and the efficient and fast way to fabricate terahertz metalenses. The used photocuring 3D printing technology can meet the demands. It is an excellent material to design the metalens, which can balance the loss and manipulation performance. Furthermore, the commercial accessible fabrication method with low cost and easy to implement has been demonstrated by photocuring 3D printing. With the highest diffraction efficiency, the metalens shows a focal spot with the diameter of 0.91λ and DOF of 24.6λ, as shown in Fig. 1(e), (g), and the manipulation and diffraction efficiencies reach 94.6% and 62.5%. With the highest manipulation efficiency, the metalens shows a focal spot with the diameter of 0.93λ and depth of focus (DOF) of 22.7λ, as shown in Fig. 1(f), (h), and the manipulation and diffraction efficiencies reach 98.1% and 58.3%. The results show that the metalenses designed by both methods can perform a filamentous focal spot in the sub-wavelength scale with a long DOF, simultaneously high manipulation and diffraction efficiencies are obtained. To further verify the imaging ability of these two metalenses, the 1951 United States Air Force (USAF) resolution test chart (Edmund, Positive Target) is used to verify the imaging ability. A transmission terahertz imaging system experimental configuration is shown in Fig. 1(i). Fig. 1(j) to 1(m) shows the recovered transmitted terahertz image in experiments demonstrated by these two metalenses. The line width and spacing of 2 mm which is less than the wavelength of 2.14 mm can be clearly observed from the results. It confirms that the metalens optimized by these two methods have the ability of penetrable imaging beyond the physical diffraction limit, and further validated the effectiveness of the proposed methods.

Figure 1 (a) The model of electromagnetic wave normal incidence into a metagrating array. (b) The schematic simulated electric field distributions of bending incident terahertz waves to different angles with different diffraction periods. (c) the schematic diagram of the metalens with the highest manipulation efficiency. (d) The simulated electric field distribution of the metalens with the highest manipulation efficiency. (e) The normalized intensity distributions of the focal spot measured by the knife-edge method in x-y plane of the metalens with the highest diffraction efficiency and (f) the metalens with the highest manipulation efficiency. (g) The experimental measurement normalized intensity distributions of the depth of focus along z-axis of the metalens with the highest diffraction efficiency and (h) the metalens with the highest manipulation efficiency. (i) The experimental configuration of the transmission terahertz imaging system. (j, k) The transmitted terahertz image of the marked area of USAF 1951 test chart demonstrated by the metalens with the highest diffraction efficiency, and with (l, m) the highest manipulation efficiency.

The authors commented that, "this work provides a technical roadmap for the design, optimization and fabrication of high-performance focusing metalenses in the terahertz band, and holds great promise for extensive applications in terahertz imaging, communications, etc. Both proposed methods can realize the design of focusing metalenses with excellent performance, they can both obtain a sub-wavelength scale focal spot with long DOF, simultaneously with high manipulation and diffraction efficiencies. The choice of methods is determined by the demand of transmission loss and focusing performance for specific applications. If the lower transmission loss is desired, the metalens with the highest manipulation efficiency is better to be chosen."