Structural colors in nature, such as those found on butterfly wings, peacock feathers, and natural opals, are commonly seen in our daily life. These dazzling effects arise from the interaction of light with microscopic, periodic structures in otherwise colorless materials. 3D printing technology based on two-photon polymerization (TPP) offers a high-precision, flexible, and cost-effective solution for fabricating intricate micro-nano structures. In this process, a laser beam acts like a microscopic brush, selectively curing low-refractive-index polymer materials (photoresists) into an array of complex structures. The interaction between light and these artificially created micro-nano structures gives rise to structural colors that not only mimic but often surpass those found in nature. This innovation opens up endless possibilities for micro-nano art and design, blending science and creativity to achieve unprecedented aesthetic and functional outcomes.

Dr. Gui Xiao and Dr. Desheng Fan from Harbin Engineering University, in collaboration with Prof. Cheng Zhang's team from Huazhong University of Science and Technology, have recently achieved a breakthrough in creating full-color and dual-information structural color patterns. This work was conducted using the two-photon polymerization laser direct writing (TPP-LDW) platform provided by Yantai Magic-Nano Technology Co., Ltd. The team employed low-refractive-index materials with tailored periodic structures to create large-scale structural color patterns spanning several centimeters. The relevant research results were recently published as On the Cover in Photonics Research, Volume 12, Issue 12, 2024. [Haoyu Pan, Desheng Fan, Linwei Zhu, Danyan Wang, Moxin Li, Jian Wang, Gui Xiao, Qiang Shi, Cheng Zhang, "Dual-information and large-scale structural color patterns by laser direct writing with a low-index tailored nanostructure array," Photonics Res. 12, 2948 (2024)]

The research methodology is illustrated in Figure 1. Figure 1(a) presents a schematic of the TPP-LDW process, where five types of nanostructures—cylindrical pillar, long-rod pillar, grating, cross-shaped pillar, and grid—are fabricated. By adjusting parameters such as laser power, writing speed, interface depth, exposure time, and laser beam path, the height, linewidth, and periodicity of the fabricated structures can be tuned, enabling precise wavelength-selective responses. Figure 1(b) shows the observed colors of different nanostructure arrays under both bright-field and cross-polarized illumination conditions. Due to the distinct polarization sensitivities of these structures, their transmitted colors vary, which can be leveraged to create dual-information patterns, as displayed in Figure 1(c).

Fig. 1 (a) Schematic diagram of periodic micro-nano-structured colors prepared by TPP-LDW; (b) Colors observed under bright-field illumination and cross-polarized illumination modes; (c) Observed dual color patterns: "The stary night" and "2023".

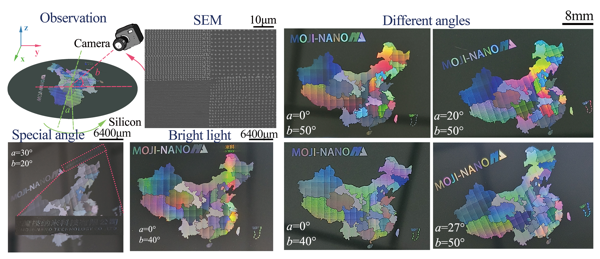

In addition, large-scale full-color patterns of 3.2 cm×2.4 cm were also printed on a silicon substrate using a cylindrical pillar array structure. The pattern can be viewed directly with naked eyes, and structure with a smaller line-width (<150 nm) and processing defects can only be observed at special angles under strong light illuminated, which can also achieve a hidden effect.

In addition, large-scale full-color patterns measuring 3.2 cm × 2.4 cm were printed on a silicon substrate using a cylindrical pillar array structure. These patterns are visible to the naked eye. Moreover, structures with smaller linewidths (< 150 nm) and processing defects are only observable at specific angles under strong illumination. This unique feature enables a hidden effect that adds an extra layer of functionality to the design.

Fig. 2 A large-scale color pattern printed on a silicon wafer

In the future, the team will continue exploring micro-nano structural colors fabricated via two-photon laser direct writing, with plans to extend 2D patterns into 3D and multi-dimensional structures. By modifying the designs, they aim to achieve wider color gamuts, color mixing with information overlays, optical rotation effects, and more. These advancements will enable more versatile forms of structural color and expand their potential applications in the real world.