Owing to its advantages of ultrashort pulse width and extremely high peak intensity, ultrafast lasers have been widely used in fabricating plasmonic nanomaterials. Laser beams with extremely high power densities heat the free electrons in plasmonic nanomaterials, thereby increasing the lattice temperature and causing photothermal reshaping. Depending on the power density of the laser beam and the melting/boiling threshold, we review three types of photothermal reshaping mechanisms: complete melting above threshold, surface atom diffusion below melting temperature, and ablation. The exemplary applications of photothermal reshaping of plasmonic nanomaterials in optical data storage, plasmonic color printing, and steganography are reviewed.

Optical fiber functional devices have huge application prospects in micromechanical structures, biomedical, ocean detection, aerospace, and other fields because of their unique advantages such as small size, high sensitivity, anti-electromagnetic interference, corrosion resistance, easy integration, and multiplexing. Femtosecond laser with ultra-narrow pulse widths can effectively avoid thermal effects and can achieve high-precision optical functional structures when interacting with materials, which has been used in fiber functional device manufacturing. At present, various three-dimensional micro-nano fiber functional devices with good stability and high resolution have been prepared by femtosecond laser direct writing technology, femtosecond laser two-photon polymerization technology, and femtosecond laser-induced water breakdown technology. Herein, we introduce the recent development of fiber grating, fiber interferometer, optical waveguide, and other micro-optical devices. Further, we analyze the future development directions and prospects of femtosecond laser micro-nano processing technology.

Spatio-temporal characteristics of ultrashort pulse has shown a vital impact on the material modification, and have gradually become a research hotspot in the field of femtosecond laser micromachining in the last decades. According to the basic concepts of the spatiotemporal coupling of femtosecond pulses, the effects of spatio-temporal coupling as well as spatio-temporal focusing techniques are reviewed briefly. Then it introduces a few applications of spatio-temporal focusing technology on material processing, and especially discusses the influence of spatio-temporal coupling on the non-reciprocal direct writing and the asymmetric nanograting structure in transparent materials.

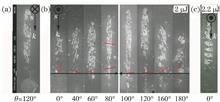

Femtosecond laser-induced periodic surface structures not only have the capability in modifying the physicochemical properties of the material interfaces, but also possess the features of mask-free and one-step processing, which promise wide applications in multidisciplinary fields. Currently, however, there are some challenges in this technology, such as the poor structural regularity, dimensional inflexibility and low production efficiency. This paper firstly reviews progresses in fabricating highly regular one-dimensional subwavelength periodic structures with the improved efficiency on metal films, under irradiation of the single-beam femtosecond laser pulses. Then we introduces novel methods to control one-dimensional structure features (including the regularity, periodicity and orientation) on both metals and semiconductors, by utilizing the collinear propagation of double femtosecond laser beams associated with certain temporal delays. Two-dimensional arrays of the subwavelength periodic structures are successfully achieved with different geometric profiles such as the triangle, rhombus, elliptical rod, and ripple-particle hybridization. Some ultrafast physical phenomena are discovered during the control formation of the periodic surface structures. The transient correlation effects between ultrafast dynamic processes of laser-material are elucidated for the incidence of temporally-delayed pulses.

When the peak power density of a short or ultrashort pulse laser exceeds the ionization threshold of the solid target or liquid medium, a plasma will be formed on the surface of the target or inside the medium, leading to the remove of the workpiece by the interaction between the plasma and the workpiece, which is called laser induced plasma micromachining(LIPMM). This processing technology is characterized by high absorption of laser energy, low damage, high efficiency and wide application, which has been widely used in the field of micromachining. The machining principle of LIPMM was firstly introduced in this paper, and the new techniques and applications of LIPMM in solid target and liquid medium were then mainly elaborated. The challenges and future trends of the development of LIPMM were finally summarized and prospected.

Compared to traditional processing methods and other advanced micro/nano processing methods, femtosecond laser direct writing technology has certain advantages in controllable micro/nano processing, such as no mask, suitable for any material, and small thermal effect. Therefore, it is always used to prepare bionic micro/nano structure surfaces for applications in various fields such as self-cleaning, oil-water separation, and water mist collection. The formation mechanism and design ideas of preparing various micro/nano structures on different materials by femtosecond lasers are analyzed, and the latest research progress on the preparation of the bionic micro/nano structure surfaces by femtosecond laser is summarized. Then, the related concepts and theoretical models of surface wettability, controllable preparation of various micro/nano structures by femtosecond laser, and related industrial applications are explored. Finally, the difficulties and challenges of femtosecond laser processing technology in the field of micro/nano manufacturing are analyzed, and its future development in related fields is prospected.

Ultrafast lasers have the characteristics of high pulse energy, high processing accuracy, and small heat affected zone. They have unique advantages in material processing, especially in the fields of micro-nano processing and surface modification. This paper introduces the typical numerical simulation methods of ultrafast laser processing metal materials. It summarizes the research progress of numerical simulation based on the three mechanisms of ablation, plasma effect, and periodic surface structure formation in recent years. Several models and limitations of these mechanisms are introduced, the current challenges of numerical simulation for ultrafast laser processing are summarized, and future research focuses are prospected.

A medical Zr-based bulk metallic glass linear structure was treated by scanning its surface using a femtosecond laser. The surface morphological changes in the samples were observed by scanning electron microscopy. The contact angles of the samples before, directly after fabrication, and three months after fabrication were measured using a contact angle meter, and the surface chemical composition was analyzed by X-ray photoelectron spectrometer. An electrochemical workstation was used to compare the corrosion speed before and after fabrication. Although the initial surface of the Zr-based bulk metallic glass exhibited a certain degree of hydrophilicity, after microstructural surface treatment by a femtosecond laser, the hydrophilicity was considerably improved. The contact angle of the surface after femtosecond laser treatment increased significantly after 3 months of indoor sealing bag preservation. The open-circuit voltage of the samples before and after processing was -0.96 V and -0.93 V, respectively. After the femtosecond processing, the Zr-based bulk metallic glass had a higher open-circuit voltage and better corrosion resistance than the unprocessed sample. Experimental results show that the bulk metallic glass surface treated by the femtosecond laser is more hydrophilic and corrosion resistant, thus enhancing its applicability as a medical implant in the human body.

Herein, (super) hydrophobic/(super) hydrophilic aluminum membranes were fabricated by nanosecond fiber laser processing combined with surfactant control. Further, the wettability and fog collection characteristics of the fabricated (super) hydrophobic/(super) hydrophilic aluminum membranes were studied. First, a microporous array was fabricated on 35-μm-thick aluminum foil using the nanosecond fiber laser drilling technology. Then, the bottom surface of the aluminum membrane was sprayed with Glaco coating reagent two-three times. Hydrophobic silica particles in the reagent adhered to the surface, thereby changing the wettability of the aluminum membrane surface. Finally, a (super) hydrophobic/(super) hydrophilic aluminum membrane was obtained using laser secondary scanning. The (super) hydrophobic/(super) hydrophilic aluminum membrane was examined for wettability, droplet penetration, and optimum fog collection aperture with varying pore sizes and the same through-hole quantity. Results showed that the pore size affected the wettability of aluminum membrane to water, infiltration time of water droplets, and function of fog collection in aluminum foil membranes with the same through-hole quantity. The optimal fog collection pore size of the synthesized (super) hydrophobic/(super) hydrophilic aluminum membrane was 108 μm, and its fog collection amount was as high as approximately 31.3 times the lowest fog collection amount.

Bioinspired slippery surface has important applications because of its ability to resist the adhesion of various liquid, even plants and animals. Femtosecond laser micromachining technology has the characteristics of material universality, high machining resolution, and high controllability and so on. Thus, it shows great advantages in the fabrication and control of surface wettability. Firstly, from the perspective of bionics, this review introduces the preparation of superhydrophobic surfaces and underwater superoleophobic surfaces fabricated by femtosecond laser, and analyzes their inherent defects in applications. Then, the preparation principle of slippery surface and the general processing technology of slippery surface fabricated by femtosecond laser are summarized. Then, different kinds of slippery surfaces and the slippery property of different liquids and bubble on these slippery surfaces which are prepared by femtosecond laser are systematically summarized. After that, typical applications of slippery surface are introduced. Finally, the problems and prospects of the preparation and applications of slippery surface fabricated by femtosecond laser are summarized and discussed.

Femtosecond lasers have the advantage of being super fast and precise, making them an ideal way to process graphene materials. In this paper, the femtosecond laser processing of graphene materials is introduced, including femtosecond laser processing of graphene thin film materials and femtosecond laser liquid phase ablation processing of graphene materials. The applications of the graphene materials processed by femtosecond laser, including microcircuits and optoelectronic devices, integrated sensors and mechanisms, and miniature supercapacitors, are also highlighted in this review.

Femtosecond laser direct writing is a highly efficient and flexible three-dimensional processing technique with high precision, which is widely used in many fields. Optical waveguide that confines light propagation in microscale channels is one of the basic components in integrated photonic devices. Laser crystals are major gain media for all-solid state lasers. The femtosecond laser direct writing that constructs the optical waveguides in laser crystals preserves the original features of bulks, and can prepare low-cost and high efficiency waveguide laser devices. Starting from two types of femtosecond laser induced structural modifications (with refractive index change) in crystal, this work reviews the categories, characteristics, and applications of laser crystal optical waveguides fabricated by the femtosecond laser direct writing. The application prospects in relevant fields are also presented.

With ultra short pulse width and high peak power, femtosecond laser plays an important role in micro/nano machining. However, the processing efficiency of femtosecond laser restricts its application in industry. In recent years, researchers have successfully applied spatial light modulator to femtosecond laser processing to further improve the efficiency and flexibility of femtosecond laser processing. In this paper, the progress of recent research of Si-based liquid crystal spatial light modulator in femtosecond laser processing is reviewed. It concludes three processing methods that is multi foci parallel processing, structured light field parallel processing, and vector light field processing. The advantages and disadvantages of these processing methods are analyzed. The recent study of the field quality is discussed in the aspects of the uniformity and diffraction efficiency of the field. Finally, the problems in this field are discussed, and the prospect for the future is put forward.

Microholes are extensively used as a common structure in various fields, including aviation, biology, chemical industry, and new energy. The femtosecond laser pulse possesses unique advantages with respect to drilling high-quality and high-aspect-ratio microholes owing to its ultrashort duration and ultrahigh peak intensity. In this study, the research progress of femtosecond laser microhole drilling on non-metallic materials and its applications in recent years, including the temporally/spatially shaped femtosecond laser pulse microhole drilling based on electron dynamic control, laser irradiation followed by chemical etching microhole drilling, vacuum environment microhole drilling, back-surface liquid-assisted microhole drilling, and environment-temperature-controlled microhole drilling, are reviewed. Furthermore, the challenges associated with the mechanisms and methodologies of femtosecond laser microhole drilling on non-metallic materials are analyzed.

Underwater gas wettable surface plays an important role in many fields, and it has been paid close attention by researchers from various countries in recent years. As a new non-contact processing method, the femtosecond laser micro-nano fabricating technology has carried out many exploratory studies in controlling material surface underwater gas wettability in recent years. The recent research progress of the femtosecond laser micro-nano fabricating technology in the underwater gas wettability field were summarized from the four aspects of underwater superaerophobic surface, underwater superaerophilic surface, underwater superaerophilicity-superaerophobicity switching and underwater gas transportation. Finally, the existing problems of the field were pointed out combining with the current research status and the prospects of the future were put forward.

Micromachining of crystal materials is a vital technology for fabricating microelectronic device and microelectromechanical system. The technology combined femtosecond laser irradiation and wet etching exhibits advantages in removing femtosecond laser-induced defects and smoothing microstructure surfaces. It also exhibits unique perks in preparing high aspect ratio structures and burying microchannels in materials, thereby facilitating a new approach for micromachining of crystal materials. This study summarizes the technical features, principles, and advantages of femtosecond laser irradiation and wet etching micro-nano processing technique and demonstrates the research progress in fabricating microstructures in crystal materials such as silicon, silicon carbide, and sapphire. The limitations and future advancements of this technology are also discussed.

Fiber gratings have the characteristics of anti-electromagnetic interference, good causticity resistance, strong plasticity, small size, light in mass, and natural compatibility with optical fiber systems. They have obtained wide applications in the fields of fiber sensing, fiber communications, fiber lasers, and so on. At present, the common fiber grating manufacturing methods include ultraviolet exposure, CO2 laser inscribing and femtosecond laser inscribing. The advent of femtosecond lasers has greatly simplified the manufacturing process of fiber gratings. As its inscribing mechanism is different from the common ultraviolet exposure method, it does not need to carry hydrogen treatment on the fiber, which is very useful for fabricating high-performance gratings on ultra-large core fibers. According to whether a phase template is used, the fiber grating fabrication using femtosecond laser is generally divided into two ways: direct inscribing and phase mask method. This paper reviews the development of fiber gratings using femtosecond lasers at home and abroad from the perspective of inscribing methods. By summarizing and analyzing the characteristics of various femtosecond inscribing methods and the application of the fabricated gratings, we point that they potentially have important and broad applications in distributed fiber sensing, wavelength division multiplexing of fiber communication, multi-wavelength lasers, high-power fiber lasers, etc.

In this study, a digital micromirror device (DMD) maskless lithography technique, combined with femtosecond laser source and large-area splicing method, was used to rapidly fabricate a large-area micro/nanostructure with high resolution and millimeter size. Moreover, the edge roughness of the structure introduced by the uneven distribution of the light field energy is improved by single optical field line scanning. This would greatly decrease the edge roughness of the line and effectively control the accuracy of the structure. In this study, positive photoresist commonly used in the semiconductor field was the main research object, and the rapid fabrications of 1 μm equidistant line arrays with an area of 7.4 mm 2 and 10 μm equidistant line arrays with an area of 38.7 mm 2 were achieved. This study provides a new method for the fabrication of large-area micro/nanostructures which can be applied in the fields of gas-liquid flow, drug transport, and crystal growth.

In recent years, with the gradual deepening of researches on the field of micro-nano integration such as microfluidics, micromachines, and microelectronics, joining among different kinds of materials has become a bottleneck in the related fields. Due to the characteristics of controllable thermal effect and high precision, ultrashort pulsed laser welding has become a hotspot in the welding of non-metallic materials. In this review article, applications and concrete cases of the welding of non-metallic materials such as glasses, ceramics, semiconductor monocrystalline materials, and organic polymers are introduced. In addition, the future trends of ultrashort pulsed laser welding are also prospected.

In this paper, periodic subwavelength ripples were fabricated on the plane and free-form surface by using nanosecond laser with wavelength of 532 nm and pulse width of 90 ns, precise five-axis motion system, and self-developed computer-aided manufacturing (CAM) program. The effects of laser fluence and scanning rate on the formation of ripples were studied. The results show that the best ripples are formed when fluence F is 7.52 J/cm 2 and scanning rate v is 7 mm/s. Combined with a laser polarization control device, a synchronous polarization control technology was developed to achieve synchronous control of the laser polarization direction, so as to achieve precise control of ripple direction. At the same time, the effect of ripple direction on the coloring effect was studied. Furthermore, a bright color pattern with clear outer contour can be obtained on a stainless steel plate, which further realizes the preparation of complex patterns on curved surfaces.

Based on the finite-difference time-domain (FDTD) method, two kinds of terahertz line grid polarizers with enhanced line structures are designed to eliminate the influences of gravity and air disturbance on the performance of polarizers. The polarizers are fabricated by femtosecond laser micro-machining. The performance of polarizers is measured by time-domain terahertz spectroscopy and is compared with that of a commercial line grid polarizer. It is found that the transmittance of the polarizers is consistent with FDTD results. The degree of polarization and extinction ratio of the polarizer with discontinuous enhancement lines are better than that of commercial line grid polarizers.

In this paper, a precision cylindrical micropore with a diameter of 20 μm near the end face of a single-mode optical fiber was fabricated by means of femtosecond laser oil-assisted machining method. A Fabry-Perot sensor with obvious light beat and Vernier effect was formed through the micropores and the end face of the optical fiber, which realized the measurement of environmental parameters. Experimental results show that the sensor has a good linear response to external temperature, humidity, refractive index, and gas pressure. The sensor exhibits a cryogenic sensitivity of -0.0669 dB/℃, a humidity sensitivity of 0.74 nm/%RH, a refractive index sensitivity of 6.5 nm/RIU, a high temperature sensitivity of 12.23 pm/℃, and a gas pressure sensitivity of 1.743 dB/MPa. The sensor has the advantages of simple fabrication, stable performance, and compact structure.

Depressed cladding waveguide is a new kind of waveguide whose unmodified core is surrounded by numerous lower refractive index tracks. It is flexible to manipulate their shapes and sizes of the cross sections while the original properties of the material are well preserved in the region of guiding core, so the waveguides can support both transverse electric and transverse magnetic polarization modes and they have an important application prospect in integrated photonics. By using femtosecond laser writing technique, the depressed cladding waveguides have been fabricated in various glass and crystal materials. The process is completed by the translational and helical focus moving, and the fast fabrication can be realized through the focal field engineering. In this review, we summarize the development of laser direct writing of depressed cladding waveguides and their wide applications to waveguide lasing, frequency conversion, temperature sensing, waveguide grating filters and integrated photonic devices, and so on.

In recent years, the graphene has gradually become a versatile material for flexible electronic devices because of its advantages such as excellent flexibility, transparency, conductivity, and mechanical strength. Laser processing technology has played an increasingly important role in the field of preparing graphene thin film flexile electronic devices due to its high processing accuracy, programmable, flexible direct write, and other characteristics. This paper first reviews the basic principles of laser reduction of graphene oxide and the research progress of laser reduced graphene oxide (LRGO) properties such as oxygen content, conductivity, patterning, structuring, and heteroatom doping. Then, typical LRGO based flexible electronic devices including sensors, supercapacitors, generators are summarized. Finally, the limitations of this technologies are put forward and their future development is prospected.

Aiming for solving the problem in the processing of ceramic gears, the influence of laser power, scanning speed, scanning times, and scanning interval on groove depth, width, and roughness by picosecond laser with 1064 nm wavelength is studied. Combining with geometric characteristics analysis of gears, a method for converting the curved surface processing of a cylindrical workpiece into plane processing is used to achieve a high-precision laser processing of ceramic gears with different tooth shapes (spur and helical gears). The average roughness of the tooth surface (Ra)is no more than 2 μm. Moreover, the proposed process is time efficient and can be applied to the processing of complex gears composed of different materials.

The photodetectors based on hyperdoped silicon exhibit advantages including high gain at low voltage, and broadband spectral response ranging from visible to near-infrared wavelengths. In this review, the mechanism of femtosecond laser hyperdoping is introduced, followed by the research progress on hyperdoped silicon photodetectors, especially the discussions on how to enhance device response, suppress dark current, improve lattice quality, and increase carrier mobility. Moreover, photodetectors are introduced for flexible optoelectronic applications. At last, the development prospects of photodetectors based on femtosecond laser hyperdoped silicon are forecasted.

In recent years, spatial light modulators have been widely applied to aberration compensation in ultrafast laser processing, multi-focus parallel machining, two-dimensional surface machining, three-dimensional bulk machining, pulse temporal and spatial shaping, and structured light machining. Here the working principle of spatial light modulators is introduced. Hologram generation algorithms of spatial light modulators are explained. The applications of spatial light modulators to the ultrafast laser processing field are elaborated.

Cutting, drilling, and surface treatment are the methods that are commonly used for the laser processing of the fiber-reinforced composites. In this study, the domestic and international research progress with respect to the laser processing of the fiber-reinforced composites are reviewed by mainly focusing on the processing of the carbon fiber-reinforced composites. Further, the characteristics and physical removal mechanism associated with the laser processing of the fiber-reinforced composites are presented, and the effects of the laser processing parameters on the processing quality and efficiency are summarized. Finally, we present the development and the associated difficulties of the laser processing of the fiber-reinforced composites.