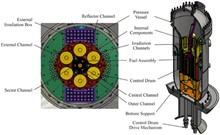

The THFR (Tsinghua High Flux Reactor) represents an advanced water-cooled high flux reactor with unperturbed average thermal and fast neutron flux levels reaching 2×1015 n?cm-2?s-1, respectively. This reactor has several outstanding features including high neutron flux, broad neutron energy spectrum, strong irradiation capability, and versatile applications. Its comprehensive irradiation performance is at the international leading level and has important applications in industries, agriculture, aerospace, medical and other fields. This paper firstly analyzes the design characteristics of THFR reactor and related systems, as well as the irradiation application system, including the vessel-in-pool reactor body structure, low neutron self-shielding reactor core design, arc plate type fuel assemblies, rotating control drums, multi-purpose irradiation channel design, and a combination of active and passive safety system design, etc. Then, the application foreground is prospected in the fields of nuclear fuel and material irradiation testing, irradiation production of radioisotopes, neutron science research, etc. THFR provides strong support for serving major strategic needs, safeguarding people's lives and health, and cultivating and developing new quality productive forces.

Z-pinch fusion fission hybrid reactor (Z-FFR) is a disruptive technology in China's advanced nuclear energy field, which is expected to be the first to achieve fusion energy break-even in the engineering sense and lead the development of advanced nuclear energy. The development situation of nuclear energy is firstly analyzed in this paper, including the current development status of advanced fission reactors and the technical and economic challenges of fusion energy development, and it is pointed out that integrated sodium-cooled fast reactor and Z-FFR have the greatest potential for development. Then, an overview of the basic principles, realization conditions, technical characteristics of Z-pinch fusion, and the research results of Chinese Academy of Engineering Physics in Z-pinch driver and fusion physics is provided in details. Finally, the differences between Z-FFR and traditional hybrid reactors are compared with emphasis on the Z-FFR design features, research results, advancements, and future development prospective.

Generation IV reactors, characterized by enhanced safety and efficiency, introduce complex thermo-hydraulic challenges due to novel coolants (e.g., liquid metals, molten salts, supercritical fluids) and multi-physics coupling mechanisms. Computational fluid dynamics (CFD) has emerged as a critical tool for addressing these challenges. In order to comprehensively analyze the application of CFD in Generation IV reactors, identify technical bottlenecks, and propose strategies for future development. A systematic review is conducted across six Generation IV reactor types, i.e., Sodium-cooled Fast Reactor (SFR), Lead-cooled Fast Reactor (LFR), Molten Salt Reactor (MSR), SuperCritical Water Reactor (SCWR), Gas-cooled Fast Reactor (GFR), Very-High Temperature Reactor (VHTR), focusing on CFD applications in component-scale flow analysis, system-level transient simulation, multi-physics coupling, and cross-scale modeling. The special requirements for fine thermal hydraulic modeling and analysis of new working fluids such as liquid metals and molten salts are summarized, and key challenges, including spatiotemporal scale discrepancies, validation uncertainties, and multi-field nonlinear interactions, are analyzed through case studies and technical comparisons. While advancements in multi-scale coupling strategies and hybrid modeling approaches have expanded CFD's predictive capabilities, significant challenges remain, including limitations in turbulence modeling accuracy, computational demands for full-core analyses, and validation gaps under extreme operational conditions. Emerging methodologies that integrate data-driven techniques with traditional physics-based models show promise in overcoming these barriers, though their broader implementation requires standardized validation protocols and improved interoperability across simulation frameworks. These developments highlight CFD's growing role in advancing reactor design while underscoring the need for systematic collaboration to bridge theoretical innovations and industrial applications. Future advancements require synergistic integration of AI-driven surrogate modeling, standardized multi-physics coupling interfaces, and cloud-based collaborative platforms. Establishing technology readiness level (TRL) matrices and open-source toolchains will accelerate the transition of CFD from research to industrial deployment in Generation IV reactor engineering.

Liquid heavy metal cooled reactors have the advantage of compact structures, high inherent safety and long service life, which have extensive application prospects on land, sea and deep space. Currently, many powerful countries in nuclear energy R&D have various research priorities and innovations in the development of key technologies for liquid heavy metal cooled reactor projects. This study summarizes the development status and the research progress of liquid heavy metal cooled reactors (mainly concentrated in lead cooled fast reactors) in Russia, United States, China, Europe, Japan and South Korea, and analyzes the performance requirements of liquid heavy metal cooled reactor in various application scenarios. In addition, the core engineering technology of liquid heavy metal reactor is further analytically refined and analyzed. It is suggested that liquid heavy metal cooled reactors technology should prioritize addressing material corrosion and interface compatibility issues, with a focus on optimizing the economic strategies of fuel cycles. Improving cross-scale simulation techniques, strengthening the ability to analyze complex thermal phenomena, validating physical models, accelerating the promotion of full-industry-chain collaboration and multi-functional application expansion are emphasized as the development trend for liquid heavy metal cooled reactors engineering.

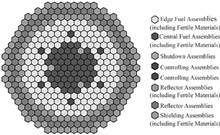

China Mianyang Research Reactor (CMRR) is a multi-purpose and high-flux research reactor, which is built at Mianyang city of Sichuan province. Focusing on the efficient application of reactor neutron resources, three scientific platforms are gradually built on CMRR, which can carry out material irradiation effect research, radioactive isotope production, neutron science research, etc. CMRR reactor adopts the design of normal temperature, normal pressure and deep-pool submergence to ensure the absolute safety of reactor in various accidents. The anti-neutron trap reactor core is designed to form the peak fast neutron flux rate of 3.4×1014 n?cm-2?s-1 in reactor active region, and the peak thermal neutron flux rate of 2.0×1014 n?cm-2?s-1 in the heavy water tank with sufficient experimental space provided for material irradiation and neutron scientific research. In this paper, the basic parameters, structure design, layout of CMRR and main research progress of CMRR reactor in material irradiation effect study, radioactive isotope production, neutron science research are comprehensively and systematically summarized.

The environmental compatibility issue of structural materials in liquid lead bismuth eutectic (LBE) is a bottleneck problem restricting the development and construction of lead-cold fast reactors. 9~12Cr ferritic/martensitic and austenitic stainless steels are the preferred key equipment structural materials for lead-cold fast reactors, but facing severe liquid metal corrosion (oxidation and dissolution) problems in high-temperature liquid LBE environments. Usually, an appropriate amount of Si or Al is added to the alloy to enhance its resistance to liquid metal corrosion. This paper reviews the research progress on the oxidation, dissolution, slow strain rate tensile, creep, fatigue and crack propagation behavior of 9~12Cr ferritic/martensitic steels, austenitic stainless steels, Si-enhanced ferritic/martensitic steels and austenitic stainless steels, and Al forming austenitic stainless steels in the liquid LBE environment. The liquid metal embrittlement sensitivity and damage mechanism of ferritic/martensitic steels (body-centered cubic) and austenitic stainless steels (face-centered cubic) in liquid LBE environment are investigated. The existing problems in the current research are summarized, and the future research directions development visions are prospected.

As a representative reactor type of Generation IV nuclear energy systems, the sodium-cooled fast reactor (SFR) has become an international research hotspot due to its fuel breeding potential, transmutation capability of minor actinides, and inherent safety characteristics. However, its design and operation are universally subject to multi-source uncertainties, including nuclear data randomness, model simplification errors, and boundary condition perturbations. These uncertainties, when coupled with complex neutronics behavior within the reactor, sodium thermal-hydraulic characteristics, and multiphysics effects under accident conditions, may lead to deviations or abnormal fluctuations in the system response of SFR, and even trigger accident risks. This paper reviews research progress in SFR system uncertainty analysis from three aspects of reactor physics calculations, thermal-hydraulic analysis, and accident safety assessment. Worldwide research achievements, technical challenges and future development trends are summarized, and current research status and future directions of uncertainty analysis for SFR in China are analytically discussed. Through systematic analysis and synthesis, safety evaluation and design optimization of future SFR systems are perspectively provided.

Alkali metals have high thermal conductivity and low melting points, making them widely used in nuclear industry and aerospace technology. In high-temperature alkali metals systems, iron-based alloys are widely used as the material of the heating wall. Due to the highly active physicochemical properties of alkali metals, oxidation and corrosion to iron-based alloys would take place under prolonged high-temperature conditions, which alters the microstructure, surface composition, and morphological characteristics of the materials, hence has influences on their mechanical and chemical properties. In this paper, the experimental methods of the oxidation and corrosion in high-temperature alkali metals system are firstly summarized, along with the oxidation and corrosion depth models and the solid metal mass loss models. The elements transport in liquid metal and solid metal during the oxidation and corrosion process are discussed. Subsequently, some methods of protection against the oxidation and corrosion are presented, such as adding buffer and surface coating. Finally, current research status and future development trend were presented.

BackgroundBending of heat pipes is an inevitable occurrence in heat pipe cooled reactors designed for shadow cone shielding and the reduction of neutron leakage. Geyser boiling, characterized by periodic fluctuations in wall temperature during heat pipe operation, is common in conventional straight heat pipes. Temperature fluctuations in straight heat pipes can reach up to hundreds of degrees Celsius, which has an adverse impact on the heat transfer performance and stable operation of heat pipes.PurposeThis study aims to analyze the impact of high-temperature sodium heat pipe bending on heat transfer performance.MethodsBoth experimental and numerical methods were applied to the analysis of geyser boiling effect of bent heat pipe in heat pipe cooled reactor. Firstly, an experimental platform was established to conduct comparative tests on straight and bent heat pipes under vertical conditions. The heat pipes were heated by electromagnetic induction heating and cooled by natural convection and radiation. The wall temperatures of the straight heat pipe and bent heat pipe were compared to analyze the effect of bending on geyser boiling phenomena. Meanwhile, a multiphase flow model was established using Fluent to simulate the internal flow within both straight and bent heat pipes.ResultsThe experimental results indicate that, under identical operating conditions, the bent heat pipe exhibits significantly lower temperature fluctuation amplitude and period during geyser boiling compared to the straight heat pipe. The simulation results reveal that the presence of the bend induces a stable stratified flow regime, replacing the slug flow typically observed in straight pipes, thus mitigating the effects of geyser boiling. The maximum wall temperature decreases by 15 ℃ in bending heat pipe.ConclusionsThe findings of this study demonstrate that bending the high temperature sodium heat pipe can effectively suppress geyser boiling, which is beneficial for enhancing the heat transfer performance and operational stability of heat pipe cooled reactors.

BackgroundLBE (Lead-Bismuth Eutectic) alloy exhibits high thermal conductivity, substantial heat capacity, and the capability to operate under normal pressure at elevated temperatures. These properties render it a primary candidate for use as a coolant in fourth-generation reactors. Inadequate mixing of non-isothermal liquid LBE within the reactor upper plenum induces non-periodic temperature fluctuations, potentially affecting the structural integrity of materials.PurposeThis study aims to reveal the temperature fluctuation characteristics for LBE in complex circulation by combining experimental data and Large-Eddy Simulation (LES) model.MethodsFirstly, the suitability of various turbulence models for simulating temperature fluctuations was validated using public available experimental data from liquid sodium tests conducted under a parallel three-nozzle configuration. Secondly, comparisons were made between the temperature fluctuation intensities of liquid sodium and LBE to illustrate the thermal similarity of these two liquid metals. Finally, under an artificial engineering boundary condition, the LES model was employed to analyze the temperature fluctuation characteristics of LBE within the reactor upper plenum structure.ResultsAnalysis results show that the temperature fluctuation intensity of LBE is 1~10 Hz, indicative of typical low-frequency fluctuations. The most pronounced temperature fluctuations occur at approximately three-quarters of the height between the reactor core outlet and the heat pipe section. At the far end of the reactor core outlet, the temperature fluctuation intensity diminishes significantly due to relatively effective mixing of non-isothermal LBE.ConclusionsResults of this study demonstrate that LES model is more suitable for simulating the transient process of temperature fluctuation of liquid metal than RANS model, providing valuable insights for assessing material thermal fatigue and optimizing the placement of measurement points within the reactor upper plenum.

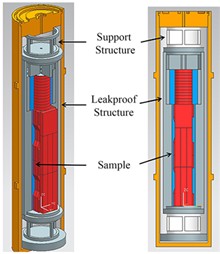

BackgroundWith the advancement of nuclear technology applications, the demand for irradiation resources continues to grow. As China's primary civilian irradiation platform, optimizing the utilization of in-core irradiation resources in the minjiang test reactor (MJTR) necessitates precise core physics calculations. Prolonged operation of the MJTR has led to neutron irradiation-induced accumulation of neutron-absorbing poisons in the beryllium reflector and control rod followers, which exacerbates deviations in fuel management simulations.PurposeThis study aims to quantify the beryllium-derived poison inventory, evaluate its impact on core neutronics, and mitigate computational inaccuracies.MethodsThe MJTR 28-1 core was selected as the research object. A dynamic beryllium poison accumulation model was established based on its geometric configuration, operational characteristics, and beryllium-neutron interaction mechanisms. Then, the Monte Carlo N-Particle (MCNP) code was applied to neutron transport simulation. Key parameters, including thermal neutron flux distribution uniformity, reactivity effects, and neutron spectrum hardening in the active core and irradiation channels, were analyzed. Finally, experimental validation was conducted through cold subcriticality measurements and axial thermal neutron flux profiling in channels 2# and 4#.ResultsSimulation results show that accumulated beryllium poison leads to a reactivity difference of 0.032 45 between poison-free and fully decayed scenarios, and spectrum hardening occurs in the active core and irradiation channels, evidenced by elevated epithermal-to-thermal neutron ratios. Thermal neutron flux homogeneity improves in the active zone due to enhanced neutron moderation. Cold subcriticality calculation deviation is reduced to approximately 1.5βeff. Simulated axial flux distributions in 2# and 4# channels align closely with experimental data, demonstrating the fidelity of beryllium poison accumulation model.ConclusionsIncorporating beryllium poison dynamics into core physics simulations significantly enhances computational accuracy. This refinement enables precise irradiation dose forecasting for samples, thereby improving the operational safety and economic efficiency of the MJTR. The methodology provides a paradigm for neutronics modeling in research reactors with beryllium-based components.

BackgroundThe heat pipe cooled reactor, characterized by compact size, high safety, and transportability, has emerged as a promising solution for nuclear energy miniaturization. Based on this design, the nuclear power system can be integrated into a standard shipping container for vehicle-mounted mobility, allowing for rapid deployment to remote areas with underdeveloped grid infrastructure, thereby ensuring a continuous and stable energy supply.PurposeThis study aims to present the previously proposed and designed Mobile Nuclear Power System (MNPS-1000), a megawatt-scale heat pipe cooled reactor system integrating open Brayton and closed Rankine cycles, while updating its conceptual design based on technical requirements.MethodsThe system comprised a 3 MWt thermal power heat pipe cooled reactor and a combined energy conversion system with combination of Brayton cycle and closed Rankine cycle. Driven by parameter matching calculations and design requirements, design analyses of the reactor system and the equipments for energy conversion system of MNPS-1000 were performed, and the layout design of the system was carried out.ResultsThe system achieves an electrical output of 1 MWe through the combined energy conversion system and can be integrated into a standard container for on-board mobile applications.ConclusionsThe conceptual design of the MNPS-1000 demonstrates the feasibility of mobile nuclear power system for energy supply, offering high energy density and rapid deployment capabilities.

BackgroundSodium-cooled fast reactors (SFRs) represent a critical advancement in fourth-generation nuclear technology, where accurate thermal-hydraulic characterization is vital for ensuring operational safety and efficiency. The complex geometry of SFR fuel assemblies presents significant challenges for conventional Computational Fluid Dynamics (CFD) approaches.PurposeThis study aims to develop and validate an optimized porous media methodology to facilitate efficient yet precise CFD analysis of SFR core thermal-hydraulics.MethodsThe investigation examined the China Experimental Fast Reactor (CEFR) core configuration, comprising 81 hexagonal fuel assemblies. Firstly, the porous media model integrated anisotropic permeability tensors to account for directional flow resistance effects induced by wire-wrap spacers. Momentum source terms were calibrated using experimental pressure drop data. Then, the computational domain was divided into four distinct regions to accommodate spatial variations in power distribution and coolant flow patterns. Additionally, to explore the influence of inter-wrapper flow (IWF) on the core's thermal-hydraulic state, modeling was performed on the inter-wrapper flow and its surrounding components. Finally, the conjugate heat transfer method was employed to calculate the inter-wrapper flow, and results were compared with the conventional CFD approach.ResultsComparison results demonstrate that the porous media model successfully predicts core thermal-hydraulic behavior with a maximum deviation of 0.7% in pressure drop compared to experimental benchmarks, and computational efficiency is significantly enhanced relative to full-resolution CFD. The inter-assembly gap flow contributes minimally to the total coolant redistribution, confirming its negligible impact on overall core performance.ConclusionsThe proposed porous media model offers a computationally efficient yet accurate alternative for SFR core analysis, demonstrating strong potential for engineering applications. The findings indicate that inter-assembly gaps can be safely disregarded in large-scale simulations without substantial loss of accuracy. This work provides valuable insights for optimizing SFR core design and improving safety assessments.

BackgroundHydrogen production based on nuclear energy plays a crucial role in achieving national major strategic goals of carbon peaking and carbon neutrality. The high-temperature gas-cooled reactor (HGTR) combined with thermochemical water splitting is considered a promising method for large-scale green hydrogen production. Safety concerns, especially hydrogen leakage and diffusion, are central to the development of nuclear hydrogen production systems.PurposeThis study aims to investigate how the parameters of hydrogen storage and environmental conditions affect hydrogen leakage, diffusion, and the minimum safe separation distance between hydrogen production plants and nuclear power plants.MethodsA numerical simulation approach was adopted to assess the leakage and diffusion behavior of hydrogen under various conditions, focusing on three main variables, i.e. internal tank pressure, tank volume, and ambient temperature. Hydrogen release and subsequent diffusion were simulated using a defined range of these parameters to evaluate their effects on gas dispersion. The Netherlands Organization (TNO) multi-energy method was applied to estimating the peak overpressure resulting from potential hydrogen explosions. Based on the overpressure thresholds, the minimum separation distance required to prevent safety accidents was predicted. All simulations were conducted under conservative assumptions to ensure robustness of the results.ResultsThe results show a clear linear relationship between internal tank pressure and hydrogen diffusion distance. When the pressure is increased from 1.0 MPa to 3.0 MPa, the diffusion radius is extended from approximately 120 m to over 230 m. The ambient temperature has negligible effects on both the diffusion distance and concentration distribution. However, a larger tank volume significantly prolongs the leakage and diffusion duration. Under the worst-case conditions simulated, the conservative minimum safe separation distance is determined to be 253 m.ConclusionsThe results of this study indicate that internal pressure and tank volume are critical factors influencing hydrogen dispersion risk whilst environmental temperature has limited impact. The findings provide valuable reference data for the safety evaluation and spatial planning of nuclear hydrogen production systems, supporting the development of safe and efficient green hydrogen infrastructure.

BackgroundLiquid metal heat pipes serve as critical thermal conductivity components in spacecraft, exhibiting excellent heat transfer and isothermal performance. However, during actual space exploration missions, sodium heat pipes may operate under conditions significantly lower than the design specifications. Such conditions can lead to liquid freezing and deposition in the condenser section, causing the working fluid to migrate toward this region.PurposeThis study aims to investigate the impact of mass migration on the operational characteristics of sodium heat pipes through experimental analysis and numerical simulations.MethodsThe sodium heat pipe with wire mesh liquid absorbing core was taken as the research object, and computational fluid dynamics (CFD) method was applied to numerical simulation of the flow field and phase change flow process inside a sodium heat pipe. Meanwhile, experiments were conducted on a full-scale (1:1) sodium heat pipe test bench, and electromagnetic coils were employed for heating whilst a water-cooled casing facilitated heat dissipation was enabling power balance adjustment. Then, the volume of fluid (VOF)-Lee-solidification-melting model was utilized to simulate the vapor-liquid-solid phase transition flow process by incorporating the capillary force of the wick via User-Defined Functions (UDF).ResultsThe experiment and simulation results indicate a heat transfer hysteresis effect during the re-start process following mass migration, leading to delayed heat dissipation and compromising the stability and reliability of system operation. The wick at the site of frozen deposition becomes obstructed by solidified material, rendering it incapable of participating in the condensation and heat dissipation processes. Consequently, the effective heat dissipation length is substantially reduced, ultimately resulting in complete failure.ConclusionsResults of this study demonstrate that mass migration adversely affects the thermal conductivity and isothermal properties of the heat pipe, thereby influencing the thermal stability of the overall system.

BackgroundIn lead-bismuth cooled fast reactors, the high-density liquid metal coolant and rapid flow characteristics introduce flow-induced vibration (FIV) risks to wire-wrapped fuel assemblies. Accurate prediction of FIV behavior is essential for assessing structural integrity.PurposeThis study aims to establish a robust numerical framework for analyzing FIV in wire-wrapped fuel rods and evaluate turbulence modeling approaches.MethodsBased on the ANSYS (Analysis System) platform, a flow-structure interaction (FSI) model was developed for a single wire-wrapped fuel rod. The applicability of the SST k-ω and large eddy simulation (LES) turbulence models was systematically compared. Sensitivity analyses were conducted for flow-solid coupling methods, including both unidirectional and bidirectional coupling. A meshing strategy was proposed to determine appropriate dimensions for the turbulence models, with sensitivity analyses performed for mesh density and time step size. Finally, the FSI model was verified by experimental data and empirical formula.ResultsThe comparison results indicate that the LES model can more accurately captures wall pressure fluctuations on the fuel rod whilst the one-way coupling method satisfies accuracy requirements for micrometer-scale vibration problems. Analysis of the seven-rod bundle model reveals that helical wire spacers cause uneven flow distribution in the flow channel while the vibration displacements of the central rods (10 μm and 40 μm) are significantly smaller than those of the surrounding rods (50 μm). The vibration is dominated by the first-order frequency without resonance, characteristic of turbulent excitation.ConclusionsThis study provides a reliable basis for rheological vibration analysis of wire-wrapped fuel in lead-bismuth fast reactors, offering significant implications for engineering design and safety assessment.

BackgroundThe lead-cooled fast reactor, as one of the important reactor types of the fourth-generation nuclear reactor, has the potential to be widely used in nuclear-powered submarines, micro-grids, and other energy supply and power supply places.PurposeThis study aims to investigate the flow heat transfer characteristics of Lead-Bismuth Eutectic (LBE) in spiral-fin fuel assembly, and provide theoretical basis and application reference for the research and design of new lead-bismuth fast reactor fuel rods.MethodsFirstly, the round-rod, wire-wrap and spiral-rib 19-rod bundle fuel assembly models were built. Then, The SST k-ω two-equation turbulence model and the Cheng turbulence Prandtl number model were used to simulate the flow and heat transfer process of LBE with boundary conditions of 19.18 kg?s-1 inlet mass flow rate and 473.15 K inlet temperature. The SIMPLE algorithm was employed to calculate pressure and velocity whilst the second-order upwind scheme was used to discretize the convective term. Finally, the flow and heat transfer characteristics in the bundle fuel assemblies were analyzed in term of the temperature distribution of coolant and the heat transfer coefficient of fuel rod surface. The turbulent cross-mixing phenomenon of LBE in the fuel assembly was analyzed from the perspective of secondary flow velocity and turbulent cross-mixing coefficient.ResultsCompared to the round rod and wire-wrap fuel assemblies, the fluid temperature uniformity inside the spiral-fin fuel assembly is better, the surface temperature of the fuel rod is significantly lower, and the average heat transfer coefficient is significantly larger. The heat transfer coefficient of spiral-fin fuel rods decreases with the increase of the distance from the central fuel rod, and the change of the heat transfer coefficient is complex, which is difficult to fit by the correlation equation. The secondary flow velocity in the subchannel is increased significantly under the effect of spiral-fin and wire-wrap, and the velocity distribution in the spiral-fin fuel assembly and the wire-wrap fuel assembly are significantly larger than that of round rod. The secondary flow velocity distribution in the wire-wrap fuel assembly has a large velocity gradient, whereas the secondary flow velocity distribution in the spiral-fin fuel assembly is more uniform. In addition, the turbulent cross-mixing coefficient of spiral-four-fin fuel assembly is significantly larger and the LBE cross-mixing between the subchannels is superior.ConclusionThe results show that the spiral-fin fuel rod has good comprehensive performance and outstanding transverse mixing characteristics, which has very good research significance and application value.

BackgroundHelical tube once-through steam generator is widely utilized in the design of advanced small reactors, forced circulation boiler and quench boiler. Flow instability is a critical thermal-hydraulic issue, but lack of comprehensive research on this phenomenon in parallel helical tubes.PurposeThis study aims to conduct experiments on a helical tubes thermal-hydraulic apparatus.MethodsThe effects of thermal parameters were investigated at the pressure range of 7~13 MPa, mass flow rate ranger of 100~550 kg?m-2?s-1 and helical coil diameter range of 370~800 mm. The flow instability in parallel helical tube channels with three different helical diameters was experimentally studied, and the effects of mass flow rate, pressure, inlet subcooling and helical diameter on the flow instability were analyzed. Based on the test data, the prediction relationship of system stability boundary was fitted. Finally, the prediction effect of straight tube heat transfer and resistance model on the stable boundary of parallel spiral tube channel was analyzed.ResultsExperimental results show that high system pressure and high inlet flow rate contribute significantly to more stable system whilst inlet subcooling has a minimal impact on the critical load at conditions with low pressure, low flow rate and low inlet subcooling. The system stability boundary exhibits an "S" shape under high system pressure but transitions to an "L" shape under low system pressure, which is associated with the multivalued influence of inlet subcooling on system stability. It is found that the critical heat load predicted by the straight tube model is 31.1%~69.9% higher than the experimental value.ConclusionsThis study fills the gap in experimental data on flow instability in parallel helical tubes, providing a solid data foundation for in-depth analysis of flow instability phenomena in the helical tube once-through steam generator.

BackgroundThe Lead-based Fast Reactor (LFR) is a highly promising fourth-generation nuclear energy system with excellent passive safety features and economic viability. However, a significant thermal stratification phenomenon occurs in the upper plenum chamber after an emergency reactor shutdown. Thermal stratification can impede the removal of residual core heat, leading to temperature accumulation and even the risk of core meltdown. Additionally, the temperature gradients within the thermal stratification in the upper plenum chamber can induce thermal stress on the internal structural components, thereby increasing the overall thermal load and causing thermal deformation of these components.PurposeThis study aims to delve into the dynamic process of LBE (Lead-Bismuth Eutectic) thermal stratification and interface evolution characteristics in the upper plenum chamber after LFR shutdown.MethodsFirstly, a simplified 1/6 scale model of the upper plenum chamber was established and computational fluid dynamics (CFD) software STAR-CCM+ was employed to conduct large eddy simulation studies on the thermal stratification process within the LFR's upper plenum chamber post-shutdown. Then, based on relevant experimental data, the accuracy of the model calculations was validated by simulating the reactor shutdown. Simulations were performed for both normal reactor operation and post-shutdown conditions, analyzing the temperature and velocity distributions within the plenum. Finally, the thermal stratification interface was defined, and its evolution was observed.ResultsSimulation results indicate that under normal operating conditions, the small holes in the inner cylinder do not significantly affect the flow of LBE within the upper plenum chamber; around 120 s after shutdown, a thermal stratification interface forms, and around 400 s, this interface rises to the top of the inner cylinder. Moreover, the small holes in the inner cylinder can significantly slow down the rate at which the thermal stratification interface rises.ConclusionsThe findings of this study suggest that there are large temperature gradients and irregular vortices at the thermal stratification interface, laying the foundation for subsequent analyses of thermal stress and thermal fatigue on structural components within the upper plenum chamber.

BackgroundThe accuracy of transient thermal-hydraulic parameters within different operational states of a reactor core is crucial for reactor safety. Rapid and precise prediction of key thermal parameter trends is essential for enhancing reactor safety.PurposeThis study aims to propose a novel prediction method of reactor transient thermal-hydraulic parameters based on Sequence-to-Sequence (Seq2Seq) neural network model for improving the accuracy and speed of predicting thermal parameters to ensure the safe operation of nuclear power plants.MethodsFirstly, Long Short Term Memory (LSTM) neural network was coupled with the Convolutional Neural Networks (CNN) to form a Seq2Seq (Sequence to Sequence) neural network model, and the wavelet decomposition was applied to preprocessing thermal parameter data. Then, the SUBCHANFLOW sub-channel program was employed to generate data samples from the China experimental fast reactor (CEFR), and results were comprehensively evaluated using the rank-sum ratio (RSR) method to derive an optimal prediction scheme. Finally, the generalization ability of this scheme was further assessed through time-series-based K-fold cross-validation and bootstrapping methods.ResultsThe coupled CNN-LSTM Seq2Seq neural network model exhibits superior predictive performance, with high accuracy and robust fitting capabilities. The maximum average relative error recorded is 0.552%.ConclusionsThe developed Seq2Seq model in this study efficiently extracts time series features and demonstrates strong generalization capabilities, providing a valuable reference for predicting critical thermal parameters in reactors.

BackgroundLiquid lithium metal is characterized by low density, high heat capacity and high thermal conductivity, which makes it suitable for cooling the reactor core in the space environment. Liquid metal has low Prandtl number (Pr), which is different from the flow and heat transfer characteristics of conventional fluid such as air and water. Therefore, the flow and heat transfer characteristics of liquid lithium need to be studied in depth to make up for the shortcomings of the existing heat transfer correlations.PurposeThis study aims to analyze the flow and heat transfer characteristics of liquid lithium in the rod bundle channel using numerical simulation for the space lithium-cooled fast reactor.MethodsThe single component rod bundle channel of the SP-100 reactor core was used as the research object in this study. Firstly, the accuracy of the SST k-ω turbulent model coupled with the Cheng turbulent Pr model used for calculating the flow and heat transfer characteristics of liquid lithium was validated. Secondly, the effect of the Peclet number (Pe) on the flow and heat transfer characteristics of liquid lithium at the same heat flux was investigated. Then, the heat flux was changed to analyze the effect of heat flux on the flow and heat transfer characteristics of liquid lithium. Finally, the variation trend of pressure drop with Pe were analyzed.ResultsNumerical simulation results show that, with the gradual increase of the Pe, the heat transfer performance of liquid lithium is gradually enhanced whilst the pressure drop in the flow process is increased. The conduction effect of liquid lithium at Pe of 120 in this assembly is comparable to the convection effect with a Nusselt number (Nu) of about 1. The size of the heat flux has a small effect on the flow heat transfer performance of liquid lithium. The pressure drop is positively correlated with Pe. The pressure drop is less than 1 kPa when Pe is in the range of 15 to 60, and when Pe reaches 1 500, the pressure drop is up to 124 kPa.ConclusionsThis study can provide a reference for the core design and safety analysis of space lithium-cooled fast reactor.

BackgroundThe construction of an International Lunar Research Station represents a key objective for the next phase of China's lunar exploration and development initiatives. Nuclear reactor power sources, capable of delivering continuous high-power supply, are well-suited for sustaining the operation of lunar bases. The TOPAZ-Ⅱ, a space nuclear reactor power source developed by the Soviet Union, exhibits a high technology readiness level and serves as a valuable reference for designing nuclear reactor power systems for lunar bases. However, its original design was tailored for low-Earth orbit applications with a relatively short operational life, rendering it unsuitable for direct deployment on lunar bases without significant modifications.PurposeThis study aims to improve the design life of TOPAZ-Ⅱ through design modifications to achieve seven years' operational life for the reactor core, addressing the long-term energy requirements of lunar bases.MethodsThe reinforced single-cell thermionic fuel elements was employed to enhance core design and increase both the moderator share and fuel loading to fulfill the reactivity demands for a 7-a operational lifespan. By incorporating fuel elements with an extended design life and adjusting parameters such as core dimensions, special attention was given to critical safety concerns, with a proposal to meet nuclear safety standards during launch by loading fuel on the lunar surface. Additionally, the reactor shutdown system was designed to include reflector slip-down as a secondary independent emergency shutdown mechanism, hence further enhancing reactor safety. Finally, neutronics characteristics of the optimized design were evaluated using the Monte Carlo code MCNP (Monte Carlo N-Particle Transport Code).ResultsEvaluation results indicate that the height of the core active zone in the improved design is increased from 37.5 cm to 44 cm, while the 235U loading is risen from 22.87 kg to 26.84 kg, satisfying the reactivity requirements for a seven-year lifespan. Fuel loading on the lunar surface fulfills special critical safety criteria, and the reflector's properties enable it to function as a secondary shutdown system.ConclusionsThrough these enhancements in this study, the TOPAZ-Ⅱ can achieve a seven-year operational life while meeting nuclear safety objectives. The findings provide a valuable reference for selecting nuclear reactor power solutions for lunar research stations.

BackgroundMolten salt reactor is a promising type of reactor with excellent safety and economy, benefiting from the stable properties of its molten salt coolant at high temperatures. However, the freezing point of molten inorganic salt is usually high enough to pose a risk of coolant freezing, which could plug the pipelines when flowing through a relatively cold place.PurposeThis study aims to present the process of the molten salt filling cold pipe with solidification-melting behaviors and estimate the mushy zone effect of molten salt with temperature near the freezing point.MethodsThe commercial CFD (Computational Fluid Dynamics) code ANSYS Fluent was used to numerically simulate the process, and the solidification-melting behaviors were solved by the enthalpy-porosity model, in which the mushy zone constant (Amush) was an important influencing parameter. By monitoring the velocity change of the characteristic interface, a set of penetration distances was simulated at different Amush values (5×103~5×105), and an existing experiment was used to deduce the mushy zone constant for molten salt.ResultsSimulation results show that penetration distance is sensitive to variations in the mushy zone constant. Based on the existing experimental value of penetration distance, Amush=5×104 is suitable to mushy zone influence estimation for molten salt.ConclusionsBased on the method proposed in this study for determining the mushy zone constant, proper selection of mushy zone constant is very much necessary to accurately solidification-melting process prediction when using the enthalpy-porosity model whilst the freezing point of molten inorganic salt is usually high enough presenting a risk of coolant freezing which could plug pipelines when flowing through relative cold place.

BackgroundThe point-burnup program is widely used in the design of nuclear power plants. However, the burnup library owned by point-bunrup program is mainly used in thermal neutron reactors such as light water reactors and heavy water reactors, not for fast neutron reactors.PurposeThis study aims to conduct research on the processing methodology of burnup libraries tailored to the characteristics of micro-fast neutron reactors.MethodsFirstly, the multi-group transport library suitable for micro fast neutron reactor was obtained by resonance self-shielding effect correction calculation. Secondly, the multi-group neutron energy spectra in the core were obtained by transport calculation based on the geometric model of micro fast neutron reactor, and then merging groups into single group effective cross sections. Subsequently, the nuclide composition at the end of the current burnup step was obtained by burnup calculation based on single group effective cross section. The above process was repeated until all burnup steps were calculated, and finally a ORIGEN-S burnup library (BULFUR-70) suitable for micro fast neutron reactor at different burnup depths was generated. Finally, calculation results for Megapower micro nuclear reactor using above-generated ORIGEN-S burnup library were verified by comparing with that of Monte Carlo program OpenMC.ResultsThe comparison results show that good agreement is exhibited for burnup calculations of the core nuclear fuel with relative errors of within ±5% (except for 239Pu, which shows a relative error of 6.24%) whilst the relative errors are within ±10% in activation calculations for structural materials such as stainless steel.ConclusionsVerification results demonstrate that the method of burnup library generation proposed in this study is correct, and the generated burnup library can be used for source term analysis and shielding analysis of micro fast neutron reactor, supporting computational analyses of core radioactive accumulation, core decay heat, spent fuel assembly source strength, and reactor inner component activation after shutdown.

BackgroundLead-Bismuth Eutectic (LBE), a promising coolant for generation IV nuclear reactors, exhibits a distinct low Prandtl number (Pr≈0.01~0.025) compared to conventional fluids like air or water (Pr>0.7). This unique property fundamentally alters its turbulent heat transfer behavior, yet systematic investigations into LBE's thermal transport mechanisms under turbulence remain scarce, limiting its engineering applications.PurposeThis study aims to simulate four-equation model for turbulent heat transfer in liquid LBE flows with multi-channel structure so as to provide theoretical support for optimizing reactor thermal-hydraulic designs and safety protocols.MethodsA four-equation turbulence model (k-ε-kθ-εθ) was implemented in commercial software STAR-CCM+ to resolve both momentum and thermal fields. Firstly, the turbulent thermal diffusivity was derived by solving the turbulent thermal energy and thermal dissipation rate transport equations using a passive scalar approach. Subsequently, the turbulent thermal diffusivity was coupled with the turbulent viscosity from the k-ε model to dynamically evaluate the turbulent Pr. Three canonical configurations, i.e., fully developed parallel plate flow, pipe flow, and rod bundle channel flow, were simulated to validate the model across representative geometries.ResultsSimulation results show that the four-equation model can successfully capture key low-Pr thermal features, resulting a good linear relationship between dimensionless temperature and wall-normal distance in the viscous sublayer of parallel plate flow, consistent with theoretical predictions; For pipe and rod bundle flows, simulated Nusselt numbers agree closely with experimental data, demonstrating accuracy in predicting wall heat flux.ConclusionResults of this study demonstrate that the k-ε-kθ-εθ four-equation model is a promising framework for modeling LBE turbulent heat transfer, overcoming limitations of constant turbulent Pr assumptions in classical models.

BackgroundThe lead-bismuth eutectic (LBE) alloy, owing to its pronounced corrosive properties, generates a series of corrosion particles upon prolonged contact with material surfaces. The migration and deposition of these particles within the medium can potentially result in clogging, thereby directly compromising the reactor's safety and reducing its operational lifespan.PurposeThis study aims to investigate the deposition velocity characteristics of particles within LBE media and the factors that influence them.MethodA solution model for determining particle deposition velocity within the boundary layer of horizontal pipes was formulated, drawing upon the particle transport equation within the Eulerian framework. After establishing the boundary conditions for the given model, it was discretized and solved utilizing MATLAB software. Subsequently, the model was validated through comparison with experimental data obtained from air media and was further adapted for application in LBE media.ResultsThe comparison results reveal that the particle deposition rate in LBE media exhibits an "S"-shaped pattern as a function of particle diameter. Notably, wall roughness exerts a significant influence on the deposition rate of smaller particles, whereas fluid velocity has a more pronounced effect on the deposition rate of larger particles. Additionally, the impacts of particle type and fluid temperature on particle deposition rate are relatively minor.ConclusionsThese findings of this study provide important theoretical support for understanding the particle deposition behavior in LBE media and have significant implications for optimizing reactor design and enhancing safety.

BackgroundThe melting point of some generation IV reactors, such as Lead-Cooled, Molten Salt, is considerably higher than ambient temperatures. Under reactor shutdown, maintenance, refueling, or the activation of emergency cooling systems, the coolant may overcool and solidify. This poses a significant risk, as coolant solidification is more likely to occur under these conditions. As a result, coolant solidification accidents have been designated as one of the design-basis accidents for generation IV reactors that use high melting point coolants.PurposeThis study aims to establish a one-dimensional solidification model with mushy zone effect based on energy conservation and enthalpy porous medium model.MethodsFirstly, a solidification layer thickness model was established based on the energy conservation equation, and a source term model with mushy zone was established based on the enthalpy porous medium model. The velocity and temperature distribution models were obtained based on the boundary layer theory. Secondly, the established one-dimensional model was compiled and coupled into the ASYST system program, forming a new system safety analysis program ASYST-SF (Adaptive SYStem Thermal-hydraulics with Solidification Function), and the designed molten salt solidification experiment was used for verification. Finally, the filling behavior of FLiBe in the pipe was simulated using ASYST-SF.ResultsThe experimental verification results show that the overall model error is less than ±10%, meeting the requirements of reactor system safety analysis. The evolution behavior of fluid temperature, solidification layer thickness, and pressure drop of the pipe filling behavior under typical working conditions is somehow illustrated.ConclusionsThe model and calculation results in this study are of great significance for improving the operational safety of molten salt reactors.

BackgroundLead-cooled fast reactor (LFR) is one of the most promising reactor types among the fourth-generation nuclear reactors. However, due to spatial constraints within the LFR system, traditional rectangular heat exchangers face practical limitations. By adjusting the layout of the heat exchanger from a rectangular to a curved arrangement, it is possible to achieve a coordinated layout with other equipment in the lead-cooled fast reactor system, effectively addressing the issue of limited space.PurposeThis study aims to analyze the heat transfer performance of curved heat exchangers under various boundary conditions and propose a compact curved heat exchanger suitable for the limited space of lead-cooled fast reactors.MethodsFirstly, a curved heat exchanger (CHX) suitable for limited spaces was designed. Then, computational fluid dynamics (CFD) software Fluent was used to analyze the performance of designed CHX with coupled heat transfer between lead-bismuth eutectic (LBE) and SCO2. Subsequently, the coupled heat transfer performance of the CHX was analyzed by changing the inlet parameters of the fluid. Finally, the effect of geometric parameters on the heat transfer performance of the heat exchanger was analyzed by changing the curvature in the ranger of 0°~2°.ResultsComputation results show that the thermal resistance primarily resides on the SCO2 side during the coupled heat transfer process between LBE and SCO2, and the heat transfer coefficient is more sensitive to changes in the mass flow rate in the SCO2 side. The curvature of the CHX has minimal impact on the heat transfer performance, indicating that CHXs exhibit strong adaptability to spatial constraints in practical conditions.ConclusionsThe results of this study provide valuable references for the design of curved heat exchangers in future lead-cooled fast reactors.

BackgroundThe heat transfer performance of trapezoidal supercritical carbon dioxide printed circuit heat exchanger plates (SCO2-PCHE) is determined by both the heat transfer coefficient and pressure drop. Traditional multi-objective structural parameter optimization of heat exchangers often encounters issues such as high computational cost and difficulty in convergence.PurposeThis study aims to effectively improve the performance of the heat exchanger by proposing a multi-objective structural optimization design method for trapezoidal SCO2-PCHE.MethodsFirst, an orthogonal experiment table was created based on the geometric structure parameters of the trapezoidal SCO2-PCHE, and Fluent software was employed to calculate the heat transfer coefficient and pressure drop. Then, the affine power law model obtained by fitting the experimental samples was used as the surrogate model of heat transfer coefficient and pressure drop, and the Strength Pareto Evolutionary Algorithm 2 (SPEA2) was applied to multi-objective structural optimization of the trapezoidal SCO2-PCHE, resulting in an optimized Pareto front. Finally, the performances of SPEA2, OMOPSO and NSGA-II optimization algorithms were compared and verified.ResultsComparison results show that the JF factor obtained by SPEA2 algorithm is 21% higher than that before optimization, better than that of OMOPSO and NSGA-II algorithms, and the optimal heat transfer coefficient and pressure drop of the heat exchanger plate obtained by the optimization method based on affine power law surrogate model and SPEA2 algorithm are 16 575.53 W·(m2·K)-1 and 173.26 kPa, respectively. The heat transfer coefficient is increased by 9.37% and the pressure drop is reduced by 27% compared with that before optimization.ConclusionsThe optimization design method proposed in this paper achieves best optimization performance, providing a solution with better heat transfer performance.

BackgroundSteam generator tube rupture (SGTR) represents a typical accident scenario in liquid lead-bismuth cooled reactors. The safety implications under SGTR conditions constitute a critical challenge that must be systematically addressed for lead-bismuth cooled reactors, spanning from conceptual design to engineering application.PurposeThis study aims to investigate the main phenomena characteristics under SGTR accident.MethodsThis study employed a two-dimensional accident analysis code based on the volume-averaged Eulerian multiphase flow model. The code's capability in simulating four typical short-term phases of SGTR accidents was validated through separated effect tests and integral effect tests, specifically evaluating pressure wave generation/propagation, gas-liquid lead-bismuth two-phase flow, break blowdown behavior and pressurization in primary circuit. The Ishii-Chawla drift-flux correlation was applied to calculating the interfacial drag forces between gas and water whilst the overestimated gas void fraction in lead-bismuth eutectic (LBE) alloy systems was improved by combining the Ishii-Chawla and Kocamustafaogullari & Ishii correlations. Subsequently, two analytical models, a damaged steam generator (SG) primary circuit model and a full-reactor SGTR accident model were established for thermal-hydraulics transient analysis and pressure wave propagation analysis.ResultsThe simulation results indicate that damaged SG channel generates pressure waves peaking at several MPa magnitude near the break, propagating radially with progressive energy dissipation. Spatial analysis results show that regions sustaining pressure >1 MPa are confined within a 25 mm radius spherical zone surrounding the breach. Preliminary assessments indicate negligible mechanical impact on adjacent intact tubes. The overpressure protection system, specifically designed for cover gas transients through safety signal triggering, demonstrate effective control of primary circuit pressure and cladding temperatures. Conservative assuming continuous primary pump operation reveals partial bubble entrainment into core regions but the risk is mitigated through a protection signal design of pump coast-down.ConclusionsThese models enabled systematic investigation of pressure wave dynamics in SG channels during rupture initiation, primary circuit pressurization characteristics with safety system responses, and steam bubble migration and distribution patterns.

BackgroundMolten salt pebble-bed reactor is a new type of reactor with a complicated heat transfer process in the reactor cavity, the verification of the reliability and accuracy for the Computational Fluid Dynamics (CFD) software applied to the heat transfer process analysis in the reactor cavity of molten salt reactor (MSR) is crucial. Therefore, a simulated experimental facility for 2 MWt solid fuel Thorium Molten Salt Reactor (simulated reactor) is set up, and the experimental data from different experiment conditions are verified by FLUENT software of CFD.PurposeThe study aims to understand the heat transfer process in the reactor cavity of MSR in detail, and to validate the reliability and accuracy of CFD method for the heat analysis for the reactor silo of MSR.MethodsFirst, a one-fourth scale three-dimensional calculation model for the reactor cavity of simulated MSR was established, meshed the calculation model and performed the mesh independence analysis. Subsequently, based on the experimental data, a UDF (User-Defined Function) was programmed to define the temperature boundary condition at the interface between the upper and lower reactor cavity models. Finally, the heat transfer process in the upper and lower reactor cavity of simulated reactor was analyzed using the CFD method and verified against the experiment data under 5 experimental conditions.ResultsThe calculation results indicate that the temperature distribution of the air in the upper and lower reactor cavity is fairly uniform, with many eddy zones present in the upper reactor cavity. As the wall temperature of the pressure vessel increases, the increase rate of heat transfer power due to both radiation and convection gradually accelerates, with radiation heat transfer power increasing more rapidly. The calculated values obtained by CFD are almost consistent with the experimental values, the largest deviations for upper and lower reactor cavity are 9.6% and 4.3%, respectively. Consequently, the CFD verification results for all temperature measuring points are fairly ideal and meet the deviation tolerances for engineering calculations.ConclusionsThis study verifies the accuracy of CFD analysis method when applied to the heat analysis for the reactor cavity of molten salt reactor, providing an important reference for subsequent thermal hydraulic analysis of the reactor cavity of a 100 MW molten salt reactor.

BackgroundThe liquid-fueled molten salt reactor (MSR) is one of the focuses of nuclear energy research, and the emergency fuel salt drain system is its unique and important safety system.PurposeThis study aims to analyze the effects of heat exchange element thimble leakage on thermal transfer characteristics of the water-cooled fuel salt drain system of MSR.MethodsFirst, the molten salt reactor experiment (MSRE) water-cooled emergency fuel salt drain system was taken as the research object, and the computational fluid dynamics (CFD) simulation was conducted to establish a multiphase heat transfer flow model including cooling water boiling and molten salt solidification. Then, based on this model, the heat transfer and flow phenomena of the heat exchange element after the thimble leakage were analyzed. Subsequently, sensitivity analyses of leak size in the range of 2~7 mm, leak locations above the bottom of thimble in the range of 0.01~1.25 m, and the pressure difference between the annular gas space and the fuel drain tank (ranging from 20 684 Pa to 48 258 Pa) were investigated.ResultsThe analysis results indicate that the molten salt flows into the annular gas space in a short time after the leakage of thimble, resulting the heat exchange power of the heat exchange element increases and the natural circulation rate accelerates. When the leak size is below a critical threshold of 5 mm, the molten salt is frozed in the annular gas space, preventing further leak of the molten salt. Otherwise, the molten salt flows out of the annular gas space and the mass flow rate of cooling water in the bayonet tube oscillates periodically. In addition, the leak location and pressure difference also affect the mass flow rate of the cooling water and heat exchange capacity of the bayonet tube.ConclusionsResults of this study provide valuable data for the engineering design of the fuel drain system for liquid-fueled MSRs.