View fulltext

View fulltext

Methane is the second greenhouse gas contributing greatly to global warming, about 80 times of CO2. Considering background of global warming and atmospheric methane growth, to catalyze total oxidation of atmospheric methane is of great importance to mitigate greenhouse effects and slow this global warming. However, catalytic oxidation of methane has always been a big challenge due to its high structural stability. In this article, research progress in total oxidation of methane under thermal-, photo- and photothermal-catalysis was reviewed. High temperature in thermal catalysis increases the energy loss and accelerates the deactivation of catalysts speedingly. Therefore, development of catalysts that oxidize methane under moderate temperatures is the main research interests. Photocatalysis provides a way to eliminate methane at ambient conditions with the assistance of solar energy, but the reaction rates are lower than that in thermal catalysis. It is worth mentioning that photothermal catalysis, developed in recent years, can achieve efficiently catalytic total oxidation of methane under mild conditions, showing a high potential application prospect. This article reviews development of three modes of catalysis, analyzes their different reaction mechanisms, advantages and disadvantages under different reaction conditions. Finally, prospects and challenges of this catalytic total oxidation are pointed out, which is expected to provide references for future research on this field.

As a high-temperature-resistant structural reinforcement material with excellent performance, alumina continuous fiber has been widely used in various fields. However, its large-scale preparation is still a great challenge due to the technical difficulty. Herein, the alumina continuous fibers were prepared using self-made aluminum sol and commercially available silica sol as precursors, in which the microstructure and composition of aluminum sol were studied to reveal their excellent spinnability. Preparation of alumina-based gel continuous fibers with length longer than 1500 m was realized by Sol-Gel combined dry spinning technology. After calcination at 1100 ℃ for 30 min, the continuous ceramic fiber composed of γ-Al2O3 and amorphous SiO2 with the diameter and mean tensile strength of 10 μm and 2.0 GPa was successfully obtained. Microstructure analyses revealed high relative density of the ceramic fibers, in which the γ-Al2O3 nanocrystals with size of 10-20 nm uniformly distributed in amorphous SiO2, resulting in excellent mechanical properties. This preparation process is environment-friendly, simple and controllable, showing great potential in practical application. The test for high temperature resistance revealed that the alumina continuous fiber can work for a long time at 1000 ℃ while it can endure as high as 1300 ℃ for a short-time service.

To study the mechanical properties at high temperature of pre-stressed ceramics which were prepared by using higher expansion coefficient materials as coating and lower expansion coefficient materials as substrate, zirconia and alumina were chosen as the coating and the substrate, respectively, to fabricate ZrO2-Al2O3 (marked as ZcAs) pre-stressed ceramics with sandwich structure. Meanwhile, Al2O3-ZrO2 pre-stressed ceramics (marked as AcZs, which has the similar section ratio between substrate and coating to ZcAs), ZrO2 ceramics and Al2O3 ceramics were set as the reference samples. Combining the results of bending strength at different temperatures with the results of Vickers indentation, the existence form of residual stress and its influence on crack propagation behavior were clarified as well as the temperature dependence of residual stress. Results show that the residual tensile stress exists in the surface layer of ZcAs, while the compressive stress exists in the substrate. On the contrary, the compressive stress exists in the surface layer of AcZs and tensile stress exists in the substrate. Due to tensile stress promoting while compressive stress inhibiting crack growth, flexural strength of ZcAs is 13.2% lower than that of Al2O3, and AcZs possesses strength 25.0% higher than that of ZrO2 at room temperature. In addition, both tensile stress and compressive stress are decreased with the increase of temperature, which is mainly attributed to the relaxation of pre-stress caused by high temperature.

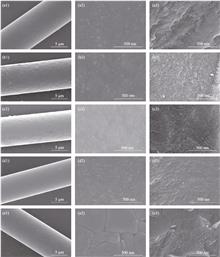

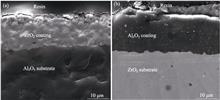

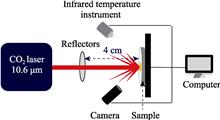

For the development of high-performance laser protective coatings, this work innovatively proposes the idea of recombining PCS ablative coatings on the surface of traditional yttrium stabilized zirconia (YSZ) thermal insulation coatings. Based on characteristics of the consumption of large amount laser energy through decomposition of polycarbosilane (PCS) and production of high-temperature ceramic protective phases, NiCrAlY/YSZ/PCS-TiO2 (YPT) and NiCrAlY/YSZ/PCS-Y2O3 (YPY) coatings were prepared on the surface of Ni-based alloy by slurry method combined with atmospheric plasma spraying (APS). Based on the effect of TiO2 and Y2O3 addition on the pyrolysis behavior of PCS, the laser ablation resistance of YPT and YPY composite coatings on 10.6 μm CO2 laser were systematically studied and compared with that of single layer YSZ coating. The results show that YPY and YPT composite coatings have better laser protection effect than traditional YSZ coating, because in the early stage of laser ablation, the PCS decomposition on the coating surface can consume laser energy, and the residual Y2SiO5, SiC and SiO2 phases after ablation can be deposited on the YSZ coating, forming a dense protective layer, which can continue to play a role in laser protection of the YSZ coating. YPY coating has better laser protection performance than YPT coating, because Y2O3 has higher thermal conductivity and lower coefficient of thermal expansion. Smaller temperature gradient can be produced in YPY coating, which can alleviate thermal stress. Moreover, Y2O3 participates in the pyrolysis of PCS to generate Y2SiO5 phase, which inhibits more volume expansion in PCS pyrolysis than that in TiO2. In addition, the core ablation temperature of YPY coating is higher, and the formation of PCS pyrolysis products SiC and SiO2 phase is faster, which can timely protect the lower coating, showing better laser ablation resistance. This study is expected to provide a new idea for the design of novel laser resistant composite coatings.

With the rapid development of industry, copper metal pollution in wastewater discharged from related manufacturing fields has become increasingly serious.Meanwhile, demand for copper metal resources in the field of catalysis is increasing. In this study, low-cost modified calcium silicate hydrate (PCSH) was prepared using fly ash and modifier polyethyleneimine (PEI) for the adsorption of heavy metal copper ions(Cu(II)) in aqueous solution, and then the Cu(II), immobilized on the surface, was further treated with alkali to form copper-based active material for catalytic degradation of organic pollutants. Compared with unmodified sample (CSH), the maximum adsorption capacity of PCSH for Cu(II) was increased by 100% with the maximum of 588 mg/g. The main reason was that the addition of PEI facilitated formation of larger specific surface area, excellent pore structure and strong complexation between Cu(II) and -NH2. The copper-based catalysts, which obtained from PCSH exhibiting spindle-shaped porous morphology, could catalyze the oxidative degradation of rhodamine B (RhB) by activating potassium peroxymonosulfate (PMS) and the reduction of 4-nitrophenol (4-NP) by activating sodium borohydride (NaBH4), with rate constants of 0.7135/min (pH (7.0±0.3); [RhB]= 20 mg/L; [PMS]= 0.12 g/L; [catalyst]= 0.8 g/L) and 11.47×10-3/s (pH (11.0±0.3); [4-NP]= 10-4 mol/L; [NaBH4]= 5×10-3 mol/L; [catalyst]= 0.167 g/L), respectively, about 20 and 19 times as large as those of CSH catalyst system, respectively. The present work achieves the reuse of copper element in aqueous solution by using solid waste fly ash, which provides new insights into effective treatment and utilization of pollutants in water.

Photocatalysis has received extensive attention due to its advantages of mild reaction conditions and direct conversion of solar energy to chemical energy. Improving the solar absorption range and reducing the recombination of photo-generated “electron-hole” pairs are the hot topics in the field of photocatalysis. In this work, the amorphous TiO2 nanotube arrays (TiO2NTs) were prepared by anodic oxidation, and indium-tin (In-Sn) alloy was pressed into the amorphous TiO2NTs by a mechanical hydraulic method to make In9.45Sn1/TiO2NTs, then the In9.45Sn1/TiO2NTs were annealed in air to obtain indium tin oxide (ITO)/TiO2NTs. The photocatalytic properties of the obtained TiO2NTs, In9.45Sn1/TiO2NTs and ITO/TiO2NTs on the removal of methylene blue in aqueous solution were studied and compared. After 180 min visible light irradiation, the degradation efficiency of the ITO/TiO2NTs reaches 96.14%. The applying UV-Vis diffuse reflectance spectroscopy (UV-Vis DRS) to explore the optical adsorption abilities of the samples shows the strongest absorbance of ITO/TiO2NTs. Combining the results of transient photocurrent responses, photocurrent density-potential, electrochemical impedance spectroscopy, and Mott-Schottky plots, the ITO/TiO2NTs have higher charge transfer capability and donor density than do other samples, which can reduce the recombination of holes and electrons, thus improving the visible-light catalytic performance. After five cycles, the degradation rate of the ITO/TiO2NTs still maintains 90.28%. Results of free radicals trapping experiments reveal that •O2- and •OH are the main active substances for the photocatalytic degradation.

In this study, one-dimensional single-crystal TiO2 nanobelt arrays with surface oxygen vacancies were constructed by Pd-catalyzed oxygen reduction method in anoxic environment to address the problems of insufficient surface active sites and slow reaction kinetics of TiO2, low yield and poor selectivity of hydrocarbons in CO2 reduction products. The effects of surface oxygen vacancies and hydrogen spillover of Pd on the separation and transport of photogenerated carrier and the selectivity of reduction product were investigated from morphological structure, carrier behavior and photocatalytic performance. With high CO2 reduction activity of Pd-Ov-TNB, yields of CH4, C2H6 and C2H4 are 40.8, 32.09 and 3.09 µmol·g-1·h-1, respectively, and selectivity of hydrocarbons is as high as 84.52%, showing great potential in C-C coupling. Its excellent photocatalytic activity is attributed to the one-dimensional single-crystal nanobelt structure that increases the active specific surface area and crystallinity of the material, provides more active sites for the CO2 reduction and accelerates the segregated transport of photogenerated charges. Meanwhile, the oxygen vacancies enhance the surface accumulation of photogenerated charges, providing an electron-rich environment for CO2 reduction. In addition, Pd nanoparticles increase concentration of H* in the reaction system, and then transfer H* to active sites of CO2 adsorption on the catalyst surface through the hydrogen spillover effect, promoting the hydrogenation of reaction intermediates. Comprehensive advantages of Pd-nanoparticals contribute to the efficient conversion of CO2 to hydrocarbons.

Oxygen reduction reaction (ORR) is an important electrochemical reaction process at the cathode of fuel cell, but its spontaneous reaction process is slow, and its catalysts, though efficient in catalyzing the ORR reaction, are facing problems of expensive price, complicated synthesis process, and polluting environment. Therefore, it is of great significance to explore the method of synthesizing a simple and environmentally friendly catalyst for the preparation of ORR catalysts. Fe-N co-doped mesoporous carbon substrate (Fe-N/MC) is a kind of non-precious metal catalysts for oxygen reduction reaction with great application value. In this work, mesoporous carbon substrate (MCM) was obtained by high-temperature carbonization of small molecule precursors in a semi-closed system in a muffle furnace, and then Fe-N co-doped mesoporous carbon substrate (Fe-N/MCMT) was prepared by mixing the obtained MCM with iron salts in a tube furnace at a high temperature. This method only needs simple pyrolysis conditions, requiring no template agents and toxic substances such as NH3 and HF. MCM is beneficial to enhance the hydrophilicity and coordination ability of the mesoporous carbon substrate surface due to its high element contents of nitrogen and oxygen. Fe-N/MCMT, prepared by MCM and iron salts, contains abundant and catalytic ORR Fe-Nx active sites with onset potential and half-wave potential of 0.941 and 0.831 V(vs RHE), respectively, which are 34 and 16 mV more positive than those of commercial Pt/C catalyst, respectively. ORR can be divided into two-electron or four-electron type according to the reaction process, and the transfer electron numbers of Fe-N/MCMT and Pt/C are 3.77 and 3.91, respectively, indicating a four-electron reaction process.

The gas diffusion layer (GDL) is a critical component of proton exchange membrane fuel cells (PEMFCs) and accounts for 40%-50% of the fuel cell membrane's cost. Developing a low-cost and high-performance GDL is imperative to advance the commercialization of PEMFCs. In this study, we generated a flexible carbon cloth with high electrical conductivity and porosity from cellulose cloth at a low temperature (1500 ℃). The carbon cloth is composed of micron-sized carbon fibers with a porosity of up to 76.93%. Through catalytic graphitization of iron-based compounds, massive carbon nanotube clusters were formed in situ on the surface of carbon fibers, which effectively enhanced the electrical conductivity of the carbon cloth. The in-plane resistance was as low as 34 mΩ·cm while the through-plane resistance was 2.8 mΩ·cm under a pressure of 2 MPa, meeting the performance standard of commercial carbon cloth. Furthermore, the PEMFC with the prepared carbon cloth as GDLs exhibits a power density of 0.4 W·cm-2 at current density of 0.7 A·cm-2, exceeding the device with commercial carbon cloth (0.34 W·cm-2 at 0.7 A·cm-2). This study demonstrates that the prepared biomass-derived carbon cloth with low-cost and high- performance holds great potential for advanced GDLs for PEMFCs.

Hybrid organic-inorganic perovskite solar cells (PSCs) have attracted global attention as one of the most promising photovoltaic materials due to their high efficiency, low energy consumption and low cost. However, non-radiative recombination caused by interface defects severely inhibits the performance of PSCs. To solve this critical issue, the particle size of nickel oxide (NiOx) hole transport layer was reduced to improve the particle size uniformity and achieve efficient hole transport. Furthermore, the antisolvent acting time of the perovskite film was optimized to reduce the interfacial non-radiative recombination and interfacial defect. As a result, the crystalline quality is improved and power conversion efficiency (PCE) of the perovskite solar cells increase from 10.11% to 18.37%. Kelvin probe atomic force microscopy (KPFM) study shows that the contact potential difference (CPD) of the optimized perovskite film in the illumination condition increases by 120.39 mV compared with that under the dark condition. Analysis by piezoelectric atomic force microscopy (PFM) reveals that the ferroelectric polarization of the optimized interfacial perovskite films hardly changes from illumination to dark states, indicating that reducing interfacial defects can decrease the hysteresis effect of the PSCs. It is concluded that optimizing the NiOx hole transport layer and improving the quality of perovskite film can reduce the interface defects, the non-radiative recombination and the hysteresis effect, and improve PCE of perovskite solar cells.

Grain refinement is an effective way to improve the mechanical properties of Bi0.5Sb1.5Te3 based alloys. However, the donor-like effect caused by the grain refinement during powder metallurgy severely degrades the thermoelectric properties of the material, which limits the application of Bi0.5Sb1.5Te3-based alloys in micro thermoelectric devices. Therefore, in this study, focusing on p-type Bi0.5Sb1.5Te3-base alloy, the impact of grinding and desorption atmosphere on donor-like effect and thermoelectric transport properties of sintered samples during powder metallurgy process were systematically studied through experiments combined with theoretical calculations. Surface defects $~\text{V}~~{\text{Te}}^{\cdot \cdot }$ and ${{\text{{V}'''}}~~{\text{Sb}}}$, generated by the grinding process of Bi0.5Sb1.5Te3-based alloy, reacts with the adsorbed O2 during sintering process. This generates a large number of $\text{V}~~{\text{Te}}^{\cdot \cdot }$ vacancies and free electrons, leading to a donor-like effect and a significant decrease in carrier concentration. The use of protective atmosphere (Ar atmosphere) during grinding to avoid exposure to air or O2 desorption under protective atmosphere after grinding effectively suppresses the donor-like effect, maintaining high carrier concentration and electrical conductivity of the sample. Moreover, the performance is stable up to 473 K. The samples treated in air or sintered using powder placed in air exhibit a significant donor-like effect, and the carrier concentration decreases from 4.49×1019 cm–3 to 3.21×1019 cm–3. The maximum thermoelectric ZT of 1.03 is obtained at 402 K for the samples sintered with the powders treated under protective atmosphere, and the overall average ZTave reaches 0.92. This study provides a new avenue to regulate the donor-like effect of p-type polycrystalline Bi2Te3-based compounds and to optimize their thermoelectric properties.

Thermoelectric materials are functional materials that can realize the direct conversion between heat and electricity, which have great prospects in the field of green refrigeration and waste heat recovery. To date, researches on thermoelectric materials mainly focus on semiconducting inorganic materials and conductive polymers. Although great progress has been made regarding material design and performance improvement, it is still of great significance to explore and expand thermoelectric candidates for potential application. Metal-organic frameworks (MOFs) are porous extended solids formed by coordination bonds between organic ligands and metal ions or metal clusters. They are promising candidates in the field of thermoelectrics due to their unique porous structure as well as tunable composition and structure, which could meet the requirement of "electron crystal-phonon glass". In this work, conductive polymer, poly(3, 4-vinyl dioxythiophene) (PEDOT) was in-situ polymerized in Zr-based MOFs UiO-67 through “conductive guest-promoted transport” approach. The confined effects originated from porous structures of MOFs on molecular chains of PEDOT effectively improve electrical conductivity of the composites. As a result, the prepared composites exhibit an electrical conductivity up to 5.96×10-3 S·cm-1 at room temperature, which is one order of magnitude higher than the corresponding PEDOT. Correspondingly, their power factor (PF) is up to 3.67×10-2 nW·m-1·K-2 at room temperature. In conclusion, this work uses ordered porous structures of MOFs as reaction platform and constructs conductive polymer/MOFs conductive materials by facile in-situ polymerization methods, providing a reference for further development of MOFs-based thermoelectric materials.

Archaeological weathered bones are usually porous and fragile, easily to warp, crack and crumble. To avoid these relic damages, consolidation technology is badly needed. Here, we explored a new consolidation method for weak bone relics using hydroxyapatite as protectant. Briefly, dispersion of calcium oxide mixed with calcium hydrophosphate in alcohol was used firstly to permeate into the fragile bones as precursor of hydroxyapatite consolidant. Then pure water was used to trigger the reaction between calcium oxide and calcium hydrophosphate, which leads to formation of a continuous phase of hydroxyapatite consolidant. By filling and bridging the pores or fissure inside the fragile bones, hydroxyapatite consolidant can act as a reinforcement material. Effects of the mass ratio of calcium oxide to calcium hydrophosphate (1 : 1, 1 : 3, 1 : 4, 1 : 5, 1 : 6, 1 : 7) and the application ways (brushing, drip infiltration and soaking) on the protective performance were investigated by scanning electron microscope (SEM), energy dispersive spectroscope (EDS), X-ray diffraction (XRD) and characterizations of color difference, weight increment, porosity, density and cohesive strength determination. The results showed that the best consolidation performance could be obtained when the mass ratio of 1 : 3 and the brushing consolidation method were adopted. In this case, porosity of the fragile bones decreased by 17.3%. Mass, density and cohesive strength of the fragile bones increased by 38.39%, 34.49% and 16.32%, respectively. Moreover, the color difference of bones is less than 3.0, which is allowable in the field of heritage conservation.

Electrochromic materials have been applied in energy-saving buildings, intelligent displays, and other fields, recognized as one of the most promising intelligent materials for research. Liquid phase method for preparation of WO3 electrochromic thin filmscan construct complex polychromies structures, showing great potential in modulation amplitude and short response time, especially in large area and low cost preparation. This study aims to develop a low-cost, easy-to-scale WO3 nanocrystalline liquid phase coating process, and improve cycle stability and preparation process. WO3 electrochromic films with high modulation amplitude, rapid response and fatigue resistance were prepared. Optimized the annealing process, WO3 nanopowders were synthesized with low aggregation and high crystallinity, and then WO3 nanocrystalline coating solution was prepared by ball milling dispersion. Thin film microstructure and coating solution crystallinity were optimized. The obtained thin electrochromic films of WO3 show high tuning amplitude (82%), short response time (tc/tb: 8 s/4.2 s), high colouring efficiency (81.5 cm2·C-1), and high cycling stability (> 1000 times). In this work, the crystallization and dispersion properties of WO3 nano-powder were modified to comprehensively improve the performance of WO3 electrochromic films prepared by nanocrystalline liquid phase coating technology. All results above demonstrate that the WO3 electrochromic film prepared by the liquid phase method is expected to be used in the future with high color-changing performance and cycle stability.

Wireless passive devices based on surface acoustic wave (SAW) technology are the firstly selected sensors in extreme conditions, and high temperature stability of piezoelectric substrates is the key factor limiting the performance of SAW devices. Langatate (LGT) crystal is an ideal high temperature piezoelectric substrate for SAW devices due to high resistivity and stability. The high temperature resistivity of pure LGT and aluminum- doped langatate (LGAT) crystals in oxygen, nitrogen and argon atmosphere were characterized, and the high temperature full matrix material coefficient of pure LGT crystal was characterized by ultrasonic resonance spectroscopy (RUS) technology. The results show that conductive behavior of LGT crystal under high temperature were significantly varied when tested in different atmospheres. The pure LGT crystal in nitrogen has the highest resistivity in the temperature range of 400-525 ℃, and in argon has highest resistivity between 525 ℃ and 700 ℃, with resistivity up to 2.05×106 Ω·cm at 700 ℃. However, LGAT crystal in nitrogen has the highest resistivity in the whole test temperature range, with a resistivity of 1.12×106 Ω·cm at 700 ℃, compared to pure LGT crystal. The elastic and piezoelectric properties of LGT crystal are very stable from room temperature to 400 ℃ according to RUS analysis results. As the temperature rises, the elastic coefficient decreases slightly, while the piezoelectric coefficient d11 is remained almost unchanged. In conclusion, LGT crystal has very high resistivity and stability at high temperature so that it is suitable to be used as piezoelectric substrate for fabricating high temperature piezoelectric devices, shedding light on the design and fabrication of LGT-based high temperature piezoelectric devices.

Silicon carbide (SiC) has wide application in electric vehicles, rail transit, high voltage power transmission and transformation, photovoltaic, and 5G communication owing to its excellent physical and chemical properties. 8-inch SiC substrate has great potential in reducing unit cost of devices and increasing capacity supply, and has become an important technology development direction of the industry. Recently, Shandong University and Guangzhou Summit Crystal Semiconductor Co., Ltd. have made a major breakthrough in the control of dislocation defects in 8-inch SiC substrates. The 8-inch n-type 4H-SiC single crystal substrate with low dislocation density has been fabricated by physical vapor transport (PVT) method, of which the threading screw dislocation (TSD) density is 0.55 cm-2, and the basal plane dislocation (BPD) density is 202 cm-2.