View fulltext

View fulltext

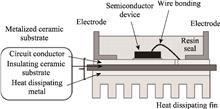

With the rise of the third-generation wide-bandgap semiconductors represented by SiC and GaN, power electronic devices are developing rapidly towards high output power and high power density, putting forward higher performance requirements on ceramic substrate materials used for power module packaging. The conventional Al2O3 and AlN ceramics are inadequate for the new generation of power module packaging applications due to low thermal conductivity or poor mechanical properties. In comparison, the newly developed Si3N4 ceramics have become the most potential insulating heat dissipation substrate materials due to its excellent mechanical properties and high thermal conductivity. In recent years, researchers have made a series of breakthroughs in the preparation of high strength and high thermal conductivity Si3N4 ceramics by screening effective sintering additive systems and optimizing the sintering processes. Meanwhile, as the advancement of the engineering application of coppered Si3N4 ceramic substrate, the evaluation of its mechanical, thermal, and electrical properties has become a research hotspot. Starting from the factors affecting thermal conductivity of Si3N4 ceramics, this article reviews the domestic and international research work focused on sintering aids selection and sintering processes improvement to enhance the thermal conductivity of Si3N4 ceramics. In addition, the latest progress in the dielectric breakdown strength of Si3N4 ceramic substrates and the evaluation of properties after being coppered are also systematically summarized and introduced. Based on above progresses and faced challengies, the future development direction of high strength and high thermal conductivity Si3N4 ceramic substrates is prospected.

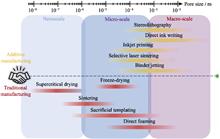

Ceramic-based porous structures not only inherit the excellent properties of dense ceramic materials such as high-temperature resistance, electrical insulation, and chemical stability, but also have unique advantages similar to porous structures, including low density, high specific surface area, and low thermal conductivity. They show great potential in various applications, such as thermal insulation, bone tissue engineering, filtration and pollutants removal, and electronic components. However, there still exist some challenges for shaping complex geometries on the macro- scale and adjusting pore morphologies on the micro- and nano-scale through the conventional preparation strategy of ceramic-based porous structures. In recent decades, researchers have been devoting themselves to developing novel manufacturing techniques for ceramic-based porous structures. The direct-ink-writing 3D printing, as one of the representative additive manufacturing technologies, has become a current research hotspot, rapidly developing a series of mature theories and innovative methodologies for fabricating porous structures. In this work, the conventional strategies and additive manufacturing strategies for obtaining porous structures were firstly summarized. The direct-write assembly processes of pore structures were further introduced in detail, mainly including pseudoplastic ink formulation, solidification strategy, drying, and post-treatment. Meanwhile, the feasibility of direct-ink-writing 3D printing technologies combined with conventional manufacturing strategies in constructing ceramic-based hierarchical pore structures was analyzed emphatically. The new perspectives, developments, and discoveries of direct-ink-writing 3D printing technologies were further summarized in the field of manufacturing complex ceramic-based porous structures. In addition, the developments and challenges in the future were prospected according to the actual application status.

Brain-inspired neuromorphic computing refers to simulation of the structure and functionality of the human brain via the integration of electronic or photonic devices. Artificial synapses are the most abundant computation element in the brain-inspired system. Memristors are considered to be ideal devices for artificial synapse applications because of their high scalability and low power consumption. Based on Ohm’s law and Kirchhoff’s law, memristor crossbar arrays can perform parallel multiply-accumulate operations in situ, leading to analogue computing with greatly improved speed and energy efficiency. Oxides are most widely used in memristors due to the ease of fabrication and high compatibility with CMOS processes. This work reviews the research progress of oxide memristors for brain-inspired computing, mainly focusing on their resistance switching mechanisms, device structures and performances. These devices fall into three categories: electrical memristors, memristors controlled via both electrical and optical stimuli, and all-optically controlled memristors. The working mechanisms of electrical memristors are commonly related to microstructure change and Joule heat that are detrimental to device stability. The device performance can be improved by optimizing device structure and material composition. Tuning the device conductance with optical signals can avoid microstructure change and Joule heat as well as reducing energy consumption, thus making it possible to address the stability problem. In addition, optically controlled memristors can directly response to external light stimulus enabling integrated sensing-computing-memoring within single devices, which are expected to be used for developing next-generation vision sensors. Hence, the realization of all-optically controlled memristors opens a new window for research and applications of memristors.

SiC ceramics with high thickness and high density are highly advantageous for armor protection, but it is difficult to produce bulk SiC ceramics with thicknesses more than 100 mm. This work was concentrated on the problems of easy cracking and non-densification in the thick SiC ceramic sintering, and degreasing products as well as pressure-incomplete degreasing process were investigated. In order to degrease thick ceramics, phenolic resin’s pyrolysis residue was examined using TG-MS. Formaldehyde and other small-molecule byproducts of breakdown were quickly eliminated, but macromolecule byproducts like dimethylphenol were easily retained in the core, leading to the noncompact sintering of thick ceramics. After degreasing optimization, the blank’s surface-core density is almost constant, ranging from 1.81 to 1.84 g/cm3. In contrast, the test group shows no cracking or deformation after sintering at 2150 ℃, and both surface and core of the large thickness ceramics obtain a density up to 3.14 g/cm3 with similar microstructure. The fracture strength of the core is (411±84) MPa, while the fracture strength of the surface is (433±48) MPa. According to the investigation, the ceramic core’s insufficient degreasing is the primary reason for the cracking and poor density.

The batch stability of ceramic powders is a core indicator that manufacturers of ceramic products are most concerned about, yet has long been undocumented. In this study, the similarity of Si3N4 powders produced in different batches was quantitatively evaluated by taking combustion-synthesized Si3N4 powders as the sample. A system of powder performance evaluation parameters covering static physicochemical and dynamic flowability indices was firstly constructed. Then, all performance data of Si3N4 powders in this parameter system were retested. Subsequently, the consistency evaluation data of Si3N4 powders were obtained using the cosine similarity method and the Euclidean distance method. The results show that both methods based on this parameter system can reflect the similarity between batches of powders and quantitatively show the differences between them. Calculation results of the two methods are mutually verified. For powders judged to be dissimilar, differences in the process were traced to find the key link in the consistency between the Si3N4 powders and the raw silicon powders. For powders judged to be highly similar, they were classified as the same class. These study provides a quantitative basis for the classification of different batches of silicon nitride powders. The “Powder Consistency Evaluation System” established in this work presents an effective evaluation tool and quantitative basis for batch stability (performance consistency) of silicon nitride powder.

Preparation of highly efficient and stable photocatalysts is crucial for the development of photocatalysis technology. In this study, the method of ultrasonic-assisted deposition and low-temperature calcination was used to prepare MoS2/g-C3N4 S-type heterojunction photocatalyst (MGCD). Effects of the phase structure, micro-morphology, optical absorption performance, X-ray photoelectron spectroscopy, electrochemical AC impedance, and photocurrent of the materials on the photocatalytic activity were comprehensively investigated. The results show that, after ultrasonic-assisted deposition-calcination treatment, MoS2 microspheres were broken, dispersed and combined on the surface of g-C3N4 nanosheets, and formed a kind of heterojunction. Under visible light, the degradation rate of 5%MGCD (with 5% MoS2 addition) for Rhodamine B (RhB) reached 99% in 20 min, and still reach 95.2% when the sample was reused for 5 times, showing good photocatalytic performance and stability. Further analysis from the point of view of the formation of built-in electric field shows that the band bending caused by built-in electric field, coupled with MoS2 and g-C3N4 in heterojunction, can effectively guide the directional migration of carriers, which can efficiently promote the separation of photogenerated carriers, thus improving the efficiency of photocatalytic reaction. Free radical capture experiment of heterojunction photocatalyst reveals that O2- and ·OH are the main active species in the catalytic degradation of RhB, followed by H+.

Al2O3-TiCp (AT) composites are frequently used as materials for metal cutting tools due to their superior mechanical properties. However, conventional sintering methods for AT materials have limitations in terms of energy consumption and cycle time. Therefore, in this study, direct additive manufacturing of AT composite ceramic materials was investigated using laser directed energy deposition technology. Effects of different TiCp ratios on the microstructure and mechanical properties of composite ceramic materials were explored. The results demonstrate that TiCp particles are uniformly distributed throughout the matrix of the fabricated samples, leading to refinement of Al2O3 grains. Stress induced by mismatch between the thermal expansion coefficients of TiCp and the Al2O3 matrix causes cracks to deflect and penetrates the particles, which consumes the crack extension energy and effectively suppresses the cracks in AT materials. Additionally, doping TiCp particles affects the molten pool by increasing the gas escape rate and improving the material density. However, high TiCp content aggravates the reaction with Al2O3 at high temperature, resulting in generation of gas and large pores in the composite material, which reduces the mechanical properties. Composites with TiCp mass fraction of 30% exhibit the best mechanical properties, with a relative density of 96.64%, microhardness and fracture toughness of 21.07 GPa and 4.29 MPa·m1/2.

To expand the utilization of iron tailings, four kinds of porous ceramics were prepared by foam gel-casting with pressureless sintering, foam gel-casting with reactive sintering, and mold forming with reactive sintering using fine-grained high-silicon iron tailings, iron tailings + graphite, and iron tailings + graphite + silicon carbide as raw materials, respectively. DSC-TG and XRD analysis was applied to investigate the sintering process of iron tailings and the carbothermal-reduction reaction between iron tailings and graphite. The four porous ceramics’ porosities, compressive strengths, and thermal conductivities were further analyzed. The results show that the porous ceramics made only from iron tailings possesses high porosity (87.2%), compressive strength (1.37 MPa), and low thermal conductivity (0.036 W/(m·K)), meeting the requirement of thermal insulation material. Silicon carbide porous ceramics with improved thermal conductivity but a slight sacrifice of strength can be fabricated through carbothermal reduction between iron tailings and graphite. Moreover, the compressive strength of silicon carbide porous ceramics can be significantly increased by adding some silicon carbide to the raw materials. The silicon carbide porous ceramics achieved high porosity of 91.6%, high compressive strength of 1.19 MPa and thermal conductivity of 0.31 W/(m·K), which can be a guarantee of a carrier for composite phase change materials or light thermal conductive materials. Compared with foam gel-casting, the mold-forming process can significantly improve the thermal conductivity (1.15 W/(m·K)) of silicon carbide porous ceramics and greatly reduce the cost of raw materials and manufacturing, which is profitable for industrialization.

Perovskite-structured praseodymium aluminum oxide (PrAlO3) exhibits high stability which has a site that can be doped with other rare earth ions, enabling it a promising new neutron-absorbing material matrix. However, the current research on PrAlO3 mainly focuses on the preparation methods of single crystal materials and their optical and magnetic property. Here, we firstly prepared a high-density perovskite phase PrAlO3 ceramics by solid-phase reaction synthesis using tetraethyl orthosilicate (TEOS) as a liquid phase sintering aid, and then studied its microstructure and thermal property by XRD, SEM, push-rod technique, and laser flash method. The results showed that, by pre-synthesizing PrAlO3 powder at 1200 ℃ and adding 0.4%-1.0%(in mass) TEOS as a liquid phase sintering aid, PrAlO3 ceramic with a relative density higher than 99% could be obtained at around 1500 ℃, while the relative density of the product without sintering aids was only 96%. The thermal conductivity of PrAlO3 ceramic at a subcritical temperature of 360 ℃ was 4.99 W·m-1·K-1, superior to those of Dy2TiO5 and GdAlO3 ceramics, and its linear thermal expansion coefficient from room temperature to 800 ℃ was only 10.2×10-6 K-1. Moreover, the bending strength and Vickers hardness of PrAlO3 ceramics reached 95.55 MPa and 7.95 GPa, respectively, and the fluorescence spectrum exhibited characteristic emission peaks of Pr3+. This study shows that high-density perovskite phase PrAlO3 ceramics can be prepared by a convenient method with good thermophysical property and mechanical property. They exhibit good application prospects as a rare earth-based neutron-absorbing nuclear material.

The SiO2-BaO-based glass-ceramics have become the focus of research in the field of high sealing resistance due to their high expansion coefficient and excellent high resistance, but the effect of rare earth oxide on modification of this kind of sealing glass-ceramics is rarely reported. Here, the effects of rare earth elements with different cation field strength (CFS) replacing traditional alkaline-earth oxide BaO on the network structure, crystallization properties, microstructures, and high-temperature resistivity of a new type of rare-earth rich-SiO2-BaO-Ln2O3 (SBLn, Ln=La, Sm, Er, Yb) series glass were studied. With the increase of rare earth cation field from 2.82 in La3+ to 3.98 in Yb3+, the glass transition temperature (Tg), crystallization initiation temperature (Tx) and crystallization peak temperature (Tp) of SBLn glass are increased, implying that the SBLn glass with higher rare earth cation field strength is more stable. Crystalline phases of the four SBLn glasses are composed of BaSiO3 and BaSi2O5 phases. When rare-earth cation field strength increases, the BaSiO3 phase decreases while the BaSi2O5 phase increases. Rare-earth elements only exist in the glass phase and do not participate the crystal phase precipitation. The crystallization amount decreases with the increase of rare earth cation field, coefficient of thermal expansion (CTE) of SBLn glass-ceramic increases from 12.52×10-6 /℃ to 13.13×10-6 /℃ (30-800 ℃), but softening temperature decreases from 1313.5 ℃ to 1174.1 ℃. In short, the CTE, softening temperature and DC resistivity at 700 ℃ of the SiO2-BaO-Ln2O3 glass-ceramics are greater than 12×10-6/℃, 1150 ℃ and 106 Ω·cm, respectively, indicating that the rare-earth-rich glass-ceramic sealant has a promising application prospect in the field of high sealing resistance, such as solid oxide fuel cell, oxygen sensors, platinum thin-film thermistor under elevated temperature.

Indoor formaldehyde (HCHO) pollution has become one of the major issues affecting human health. Catalytic formaldehyde oxidation technology employing oxygen as oxidant has received extensive attention owing to its mild conditions and nontoxic byproducts, but developing affordable and effective catalysts remains a significant hurdle. In this work, α-Ni(OH)2 was prepared through one-step hydrothermal method and its catalytic formaldehyde oxidation mechanism was investigated. The greatest catalytic formaldehyde elimination rate of 71.2% was demonstrated by α-Ni(OH)2 at room temperature, which was made with water as the solvent and nickel nitrate as the nickel source. In situ DRIFTS and theoretical calculations revealed that, due to abundant hydroxyl functional groups on the surface of α-Ni(OH)2, there was strong interaction between adsorbed formaldehyde and hydroxyl group on the surface of α-Ni(OH)2, which promoted formaldehyde activation and achieved oxidation of formaldehyde without oxygen. On the other hand, the XPS spectra of α-Ni(OH)2 treated under different conditions confirmed that the active sites of catalytic formaldehyde oxidation were Ni3+, and oxygen accelerated the recovery of Ni3+ active sites. The surface hydroxyl group of α-Ni(OH)2 cooperated with the Ni3+ active sites achieved excellent catalytic efficiency of formaldehyde oxidation, which was obviously different from the traditional formaldehyde oxidation path with oxygen dissociation as the speed control step. Our work presents a new formaldehyde oxidation pathway controlled by synergy of surface hydroxyl and active sites, and offers a theoretical foundation for the actual use of catalytic formaldehyde oxidation.

AlN-SiC multiphase ceramics possess robust mechanical strength, high thermal conductivity and good oxidization resistance, and show great potential as the matrix material of fiber reinforced ceramic matrix composites. In this work, AlN-SiC multiphase ceramics were fabricated via low temperature reactive melt infiltration of Si-Al alloy into porous C-Si3N4 preforms. Influence of Si-Al source on the melt infiltration process was studied, and impact of residual silicon on the mechanical and thermal properties of the AlN-SiC ceramics was investigated. It was found that an Al-O layer was in-situ formed at the interface between Si-Al melt and C-Si3N4 preform, when Si-Al powder was used as the infiltration medium. This seriously retarded the melt infiltration process and made the penetration of Si-Al melt into the C-Si3N4 preform hardly possible. However, when Si-Al ingot was used as the infiltration medium, a well infiltration of Si-Al melt into the C-Si3N4 preform occurred, which led to the formation of dense AlN-SiC ceramics. Mechanical and thermal property measurements indicated that the strength of the AlN-SiC ceramics was significantly improved as the residual silicon content in it was reduced, while a reverse trend was observed for the thermal conductivity. AlN-SiC ceramics with 4%(in mass) residual silicon showed a high strength of 320.1 MPa, nearly comparable to that of conventional reaction bonded SiC, although its thermal conductivity was modest (26.3 W·m-1·K-1). The fundamental reasons for the above phenomena were discussed. This study is of great significance for the preparation of SiCf/AlN-SiC composites by low temperature reactive melt infiltration.

La2O3-TiO2 glasses show promising application prospect in fields of lenses, optical windows, and optical communication, owing to their high refractive index and excellent performance. However, this glass cannot be prepared into large size because of its weak glass forming ability, which seriously limits its application. In this study, introducing the network former GeO2 can effectively improve the glass forming ability, so that large-sized GeO2-La2O3-TiO2 (GLT) glass can be prepared using conventional methods. Differential thermal analysis shows that GLT glasses have high glass transition temperature (Tg) and strong resistance to precipitation, with Tg and ΔT (Tc-onset-Tg) greater than 833 and 209 ℃, respectively. The refractive index is up to 2.06. The transmittance can reach 78% in the visible and near-infrared wavelength bands. The glass forming ability and thermal stability can be weakened by increasing the content of TiO2. The molar volume and oxygen electron polarizability exhibit the same variation trends as the refractive index of the samples. This result is important for developing new devices with high performance, light weight, and small size.

In a high vacuum environment, some organic molecular pollutants such as hydrocarbon and siloxane are released by spacecraft materials and deposited on the surface of the sensitive parts of spacecraft devices, which has become an important adverse factor restricting the development of long-life and high-performance spacecraft. Zeolite molecular adsorber coating can effectively collect spatial contaminations in real time, but the adsorption mechanism is not clear. To deeply analyze the adsorption mechanism of zeolite on the spatial contaminations, the adsorption behaviors of NaY zeolite including adsorption isotherms, adsorption heat curves and density distributions on three typical contaminations, toluene(C7H8), dimethyl phthalate (C10H10O4), octamethyl cyclotetrasiloxane (C8H24O4Si4), were calculated by the Grand Canonical Monte Carlo method in this work. The NaY zeolites and pollutant models were successfully constructed, and the rationality of the models was verified by comparing simulated data with experimental ones. These results indicated that all three classic molecules can be adsorbed by NaY zeolite in the ultra-high vacuum condition. The saturated adsorption capacity decreases in the order of C7H8>C10H10O4>C8H24O4Si4, which is significantly related to the molecule sizes and structures of contaminations. The saturated adsorption amount of C8H24O4Si4 is relatively low (8 per cell) when that of C7H8 is 36 per cell. In addition, the density distributions indicates that different contaminations are preferentially adsorbed inside the super-cage of NaY zeolite. Overall, this work analyzes the adsorption mechanism of NaY zeolite on typical contaminations, and can provide basic insights for the development of zeolite molecular adsorber coating with high adsorption capacity.