View fulltext

View fulltext

LaMgAl11O19 (LMA) coating prepared by atmospheric plasma spraying has large amounts of amorphous phase, which seriously affects the service life of coating. Effects of microstructure, such as grain size, porosity and amorphous phase content, on mechanical, thermophysical and thermal shock resistance properties of LMA coatings after heat-treatement at 900-1600 ℃ for 12 h were investigated. The results show that the as-sprayed LMA coating possesses two crystallization temperature points, 900 and 1163 ℃. After heat-treatement at 900 ℃, the lowest thermal diffusivity of 0.53 mm2/s was obtained for LMA coating at 1000 ℃ due to the large amount of amorphous phase and the highest porosity of (18.88±2.15)%. LMA coatings, heat-treated at 1100-1400 ℃, exhibited higher hardness owing to reduced amorphous content and porosity through recrystallization and sintering with the maximum hardness of (12.08±0.58) GPa at 1100 ℃. After heat-treatement at 1300 ℃, the coating displayed the highest average thermal cycling life (588 times), which attributed to abundant micron flake crystals with high strain tolerance. When the heat-treatment temperature reached 1500 ℃, the grain thickness increased rapidly due to parallel stacking of lamellar crystals, porosity increased and mechanical properties significantly decreased. During the thermal shock, grain breaking and crack propagation occurred in the coating due to the repeated thermal stress, resulting in final failure of the coating.

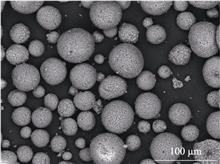

With the increase of packaging density of power electronic devices, the development of thermal interface materials with excellent thermal conductivity has received widely spread attention. Due to most traditional heat conductors showing relatively low thermal conductivity, synthesis of new high thermal conductive fillers is an important way to improve the thermal conductivity of thermal interface materials. In this study, boron phosphide (BP) particles were synthesized by a facile molten salt method, then mixed with boron nitride (h-BN) and filled into epoxy resin (EP) to prepare epoxy resin matrix composites (BP-BN/EP) by stirring and casting. With the three salts (NaCl : KCl : LiCl) method, the experimental data showed that the highest yield of BP reached 74%, 33% and 35% higher than that of the single salt method (41%) and the double salt method (39%), respectively. In the BP-BN/EP composites, BP and BN particles were uniformly dispersed in the EP matrix. When the hybrid filler loading at 30% (in volume), the thermal conductivity reached 1.81 W·m-1·K-1, 8.6 times of that of pure epoxy (0.21 W·m-1·K-1). The thermal conductivity improvement was related to the construction of thermal conductive network by BP particles linking adjacent BN sheets. In addition, to excellent thermal conductivity, the BP-BN/EP composites also showed good thermal stability and good thermodynamic properties. Therefore, the synthesized BP by molten salt method has great application prospects in the field of heat management.

YAG transparent ceramics have been widely used in the fields of laser medium and optical windows due to their excellent optical and mechanical property. The research of large-scale and complex shape YAG transparent ceramics has become a hot and difficult point of current research. As an important colloidal based forming method, spontaneous coagulation casting has shown big potentials for preparing large-scale ceramics. However, long gel curing time and low green strength are main challenges for applications. Here, water soluble epoxy glycol diglycidyl ether (EGDGE) was used to modify the spontaneous solidification forming system, and YAG transparent ceramics with different EGDGE contents were prepared by high temperature solid phase synthesis method. The influence of EGDGE addition on slurry rheology, gel strength, green porosity, ceramic microstructure, and optical property after sintering was analyzed. The results showed that the addition of EGDGE enhanced the gel curing ability of the slurry, and deformation and cracking of YAG ceramic green body were overcame. The prepared YAG green body with 0.8% (in mass) EGDGE can be sintered at 1700 ℃ for 6 h in vacuum and followed by hot isostatic press sintering at 1650 ℃ for 3 h, under 180 MPa argon pressure. The obtained YAG transparent ceramic with dimension of 90 mm×30 mm× 4.5 mm has an in-line transmittance of 80.8% at 1064 nm. This research provides a new way for the preparation of YAG transparent ceramics with large-size/complex structure.

Si3N4 ceramics have become one of the most promising materials for third-generation semiconductor’s ceramic substrates due to its excellent mechanical and thermal properties. In this work, seven rare earth oxides (RE2O3, RE=Sc, Lu, Yb, Y, Gd, Nd, La) and non-oxides (MgSiN2) were used as composite sintering additives to prepare Si3N4 ceramics with high strength and high thermal conductivity by hot pressing sintering and annealing. The effects of RE2O3 types in the composite additives on the phase composition, microstructure, mechanical properties, and thermal conductivity of Si3N4 ceramics were systematically studied. The mechanical properties of Si3N4 ceramics after hot pressing sintering were superior to that without hot pressing, and the bending strength of the sample with Nd2O3-MgSiN2 additive reached (1115±49) MPa. After annealing, the thermal conductivity of Si3N4 ceramics increased significantly, and gradually increased with the decrease of the rare earth ion’s radius. The thermal conductivity of the sample with Sc2O3-MgSiN2 additive increased from 54.7 W·m-1·K-1 to 80.7 W·m-1·K-1 (increased by 47.6%) after annealing. The results indicate that Sc2O3-MgSiN2 is expected to be a new composite additive for the preparation of high strength and high thermal conductivity Si3N4 ceramics as compared to the internationally accepted combination of Y2O3-MgSiN2 and Yb2O3-MgSiN2 additives.

Graphene has played a major role in wearable electronic textiles due to its excellent electrical conductivity, superior flexibility and environmental stability. In this work, a green-yellow reversible electrothermochromic fabric was constructed via a facial double side coating. The self-made graphene paste is coated on the surface of polyester fabric by screen printing technology. The hybrid thermochromic ink with reversible color-changing property is coated on the opposite side of the graphene layer by screen printing technology. Structural properties and discoloration principle of the fabric were analyzed. Their thermal and color-changing properties were studied by using infrared thermal imaging and colorimeter. The results show that the graphene forms a conductive layer with a thickness of 250 μm that allows Joule heating to supply the thermal resource for the electrothermochromic behavior. This fabric changes from green to yellow with a gradual heating that exceeded 45 ℃ at 12 V due to the ring closure and opening of crystal violet lactone. Its color change response time is about 15 s, while fading response time is about 27 s. The electro-thermochromic fabric is not disturbed once undergoing a bending angle range from 30° to 180° and the voltage-current curve remains stable. Performance of the fabric does not significantly degrade after 200 heating/cooling continuous cycles. In conclusion, a sensitive electro-thermochromic fabric with good cycle performance from green to yellow with the structure of graphene film‖polyester fabric‖thermochromic film is successfully prepared, which has a high application potential in the fields of military camouflage and wearable display.

Electrochromic materials can be used in new display devices because of their color-changing properties with applied voltage. The current multicolor electrochromic devices (MCECDs) are mostly prepared using several organic materials of different colors, and their process is relatively complicated, leaving preparation of simple MCECDs is still a challenge. In order to simplify the preparation process, we proposed a Prussian blue analogue composite electrochromic (MC PBA) film with four typical color states of red, blue, green, and yellow for excellent performance ECD. In this work, the preparation of a Zn-Fe Prussian blue analogue composite (Zn-Fe PBA) film was proposed by a two-step electrodeposition method. It has only one pair of redox peaks in the cyclic voltammetry curve, which corresponds to the redox reaction between FeⅢ/FeⅡ. The electrochemical performance of the Zn-Fe PBA film is excellent, which hardly degrades after 10000 cycles. It is white with almost no color change during electrochemical redox, and does not affect the color when assembling multicolor electrochromic device (Z-MCECD) with MC-PBA film. In addition, the Zn-Fe PBA film is used as ion storage layer which can significantly reduce the overpotential from 4.0 V to 1.5 V in the corresponding ECD. Benefiting from the advantages of Zn-Fe PBA film, Z-MCECD maintains four typical color states of red, blue, green, and yellow, while the operating voltage is lower and the cycle stability is also significantly improved. The transmittance control range within 2400 s was almost no attenuated, and after 3600 s, transmittance still maintained 74.4% of the initial, while the multicolor group experienced completely irreversible performance loss after 1200 s. Z-MCECD has great application potential in color electrochromic display field.

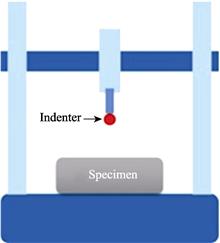

MgAl2O4 transparent ceramics possess excellent optical property, but their practical applications are somewhat restricted by the hydrolysis problem during the shaping process and limited mechanical property. Meanwhile, it has been demonstrated that the property of quaternary MgAlON spinel can be effectively adjusted via varying their composition. Accordingly, a novel Mg0.9Al2.08O3.97N0.03 transparent ceramic with a broad transmittance range was prepared by combining aqueous gel-casting, pressureless sintering, and hot isostatic pressing treatment. Optical and mechanical property of this transparent ceramic were systematically investigated and compared with those of MgAl2O4 transparent ceramic. Furthermore, the slow crack growth under low stress were analyzed, and the service life of transparent ceramic was predicted. It is shown that the viscosity of ceramic slurry with 50% (in volume) solid load was 124 mPa·s, which could meet the requirement of aqueous gel-casting. The in-line transmittance of 86.2% at 3.7 μm was obtained in the Mg0.9Al2.08O3.97N0.03 transparent ceramic sample with thickness of 2 mm, and the optical transmittance range was comparable to that of MgAl2O4, with slightly higher refractive index and Abbé number. Further, this ceramic showed a Weibull modulus similar to MgAl2O4, and although its crack slow growth coefficient is lower than MgAl2O4, but both the characteristic strength (210.6 MPa) and inert strength (227.5 MPa) were much higher. Therefore, in the quaternary MgAlON spinel with low nitrogen content, the hydrolysis problem of ceramic powders could be well overcome, while the mechanical property of transparent ceramic was remarkably improved without degradation of optical property. This research provides a new pathway toward obtaining the novel spinel transparent ceramics with improved preparation and property.

Industrial pulse energy storage multilayer ceramic capacitors (MLCC) are important components for the development and production of electronic starting devices in China. In view of the shortcomings of large size, short life and low reliability of organic film capacitors, SrTiO3 and CaTiO3 based pulse energy storage dielectric ceramics were prepared by traditional solid-state reaction method in this study. The effects of sintering aid doping and Sr2+/Ca2+ mutual doping on the dielectric properties of ceramic materials were studied, and the property of MLCC based on (Sr,Ca)TiO3 were further prepared and investigated. The results show that the dielectric constant of SrTiO3 materials can be improved by adding the sintering aid with a mass ratio of 1.0%, such as the introduction of trace Bi3+, while Bi3+ has no obvious effect on the CaTiO3 based materials. Doping of Mn element can effectively inhibit the reduction of Ti4+ during high-temperature sintering and reduce dielectric loss. Moreover, the addition of sintering aid can effectively reduce the sintering temperature of ceramic powder and improve the compactness of the material. The MLCC prepared from (SrxCa1-x)TiO3 material can maintain high dielectric constant and low dielectric loss, at x=0.4, the dielectric loss tanδ=1.8×10-4, the breakdown strength is 59.38 V/μm, and the high and low temperature discharge current change rate is ±7%, which shows good discharge stability. In addition, no matter it is at room temperature or high temperature (125 ℃), the sample has no failure after 1000 cycles of discharge experiment. Therefore, the as-obtained (Sr, Ca)TiO3 based ceramic dielectric material can be a promising pulse capacitor with relatively excellent capacity stability and high reliability under different electric field strength.

Biomaterials with both antibacterial and tissue repair activity have promising applications in the field of regenerative medicine. Both photothermal and magnetothermal-based techniques have antimicrobial effects, but the limited penetration capacity of light and the low thermal conversion efficiency of magnetothermal reagents limit their applications in biomedical fields. Here, we synthesized Fe2SiO4/Fe3O4 biphasic composite bioceramic powders, which not only display good photothermal and magnetothermal effects, but also effectively release active Fe and silicate ions, and prepared electrospun membranes by combining ceramic powders with gelatin/polycaprolactone, which not only exhibit good cytocompatibility, but also, importantly, possess both photothermal and magnetothermal properties. The composite membranes, under conditions of being irradiated with near-infrared light (808 nm, 0.36 W·cm-2) and placed in alternating magnetic field (506 kHz, 837 A·m-1) for 15 min simultaneously, are able to inhibit bacterial activity more effectively than the thermal treatment with near-infrared light or magnetic field alone. Therefore, this Fe-Si-based bioceramic and its composite material with photothermal, magnetothermal, antimicrobial, and biocompatible properties, have potential application in the field of regenerative medicine.

Mesoporous organic-inorganic hybrid siliceous hollow spheres (MOSs) were successfully synthesized by co-condensation of tetraethylorthosilicate (TEOS) and 1, 2-bis(triethoxysilyl)ethane (BTSE) with reverse micelle as template under basic condition. Structure and property of the prepared samples were characterized by different methods. The MOSs was used for VOCs removal with commercial silica gel (SG) and activated carbon (AC) as references. It is found that the sample with initial BTSE/(BTSE+TEOS) molar ratio of 10% (MOS-10%) displays uniform hollow mesostructure with the highest static VOCs adsorption capacities (1.28 g·g-1 n-hexane, 1.25 g·g-1 toluene and 1.14 g·g-1 92# gasoline), and the lowest water vapor adsorption capacity of 0.630 g·g-1. Dynamic single component (n-hexane, toluene adsorption under dry condition or n-hexane adsorption under high humidity condition, 95% RH) adsorption results show that MOS-10% has the best breakthrough times, adsorption capacities, and hydrophobicity. For binary component (n-hexane and toluene) adsorption, MOS-10% preferred to adsorb n-hexane rather than adsorb toluene. The higher dynamic VOCs capacity of MOS is attributed to the cooperation of the introduced organic groups, surface area and pore volume. The MOSs with high VOCs removal capacity and excellent recyclability show great potential for VOCs adsorption.

In the photocatalytic hydrogen production reaction, the introduction of cocatalyst to promote the rapid transfer of photogenerated electrons is an effective way to improve the photocatalytic activity. At present, the most efficient cocatalysts are mainly precious metals, greatly restricting the use of this method. In this study, influence of the close interface between non-noble metal cocatalyst CoN and g-C3N4 0D/2D on the performance of photocatalytic hydrogen production was explored. The results showed that the support of non-noble metal cocatalyst CoN can effectively improve the photocatalytic hydrogen production of 2D g-C3N4, and the support amount also has an positive effect on its activity. The compact 0D/2D interface is favorable for the rapid transmission of photogenerated electrons. Photocatalytic efficiency of 10% CoN/2D g-C3N4 composite reached 403.6 μmol·g-1·h-1, 20 times of that of 2D g-C3N4 monomer, which was comparable to that of noble metal cocatalyst. As a hydrogen evolution cocatalyst, loaded CoN can significantly promote the charge transfer process, thus greatly improving the activity of photocatalytic hydrogen evolution.

It has received extensive attention to modify polyolefin separator by boehmite coating for the improvement of thermal stability and electrolyte wettability, but how to affect the electrochemical performance of the boehmite- coated separators is unclear. In this work, boehmite nanosheets with a mean particle size of 150 nm were synthesized by a simple hydrothermal method, and these nanosheets were coated on the surface of polyethylene (PE) separator by a scraper. The boehmite nanosheet-coated separator has porosity of 46.6%, electrolyte uptake of 138.9%, ionic conductivity of 0.47 mS/cm, and lithium-ion transference number of 0.42. The battery assembled with this separator exhibits good cycling stability, retaining 93.7% discharge specific capacity after 100 cycles at 1C (1C= 150 mA/g). Meanwhile, the boehmite nanosheet-modified separator has a uniformly distributed pore structure, which optimizes the lithium-ion transport flux and suppresses the formation of lithium dendrites.

Lithium-ion batteries (LIBs) are widely applied to various portable electronic devices and new energy vehicles. However, the traditional graphite anode with low theoretical capacity (372 mAh/g) is unable to meet the need of the rapid development of economy and society. Herein, a zinc-based metallic organic framework (ZIF-8) derived three-dimensional network carbon coated silicon (Si@NC) composite was designed for lithium-ion battery. Firstly, the surface of nano-silicon was chemical modified; secondly, small size ZIF-8 was in situ grown on the silicon surface to form Si@ZIF-8; finally, the three-dimensional network Si@NC composite was obtained by carbonization. Results show that the three-dimensional network porous structure of the Si@NC composite not only limits the volume expansion of silicon, but greatly improves the conductivity of the materials, exhibiting excellent cycle stability and outstanding rate performance. As a result, a discharge specific capacity of 760 mAh/g is maintained at a high current density of 5 A/g. Using commercial material as cathode and Si@NC as anode, the assembled full LIBs demonstrate a capacity retention of 60.4% at 0.4C (1C =160 mA/g) for 50 cycles. These results indicate that the as-synthesized three-dimensional network porous structure of Si@NC composite has a potential practical application for LIBs.

Improving the high rate performance of lithium manganese spinel is one of the key research directions of Li-ion battery. In this study, spinel Li1.1-xKxMn2O4 (0≤x≤0.03) was synthesized by a high-temperature solid-state method. The results indicate that K+ doping significantly improved the high rate performance of the cathode, while the discharge specific capacity of the electrode decreased with the current density increasing. With the optimum doping amount of 1.0% (molar fraction) K+, the discharge specific capacity of the cathode increased by 102.8% at 10C (1C=150 mA·g-1), much higher than that (1.9%) at 0.5C. It can be attributed to the following points: K+ doping can firstly expand the cell volume and the Li-O bond length, lower the cation mixing of Li/Mn, and increase the content of carriers (Mn3+) of the material. Secondly, K+ doping can reduce the electrode polarization and charges transfer resistance, which develops the charge-discharge reversibility, electrical conductivity as well as the diffusion capability of the Li ions for the cathode. Thirdly, K+ doping can stabilize the framework of [Mn2]O4, degrade the change of internal stress during the electrochemical process, which inhibits the modification of the crystal structure and particle fragmentation. In addition, the existence of K+ promotes the agglomeration of the material during the preparation process, which reduces the contact area between the electrolyte and cathode in cell, thereby alleviating the erosion of the electrolyte, as well as the Mn dissolution of the cathode.

Ultra-high nickel material as a new lithium-ion battery cathode has attracted much attention due to its high specific capacity, high voltage and low cost. However, the generated microcracks, mechanical pulverization and irreversible phase transformation during cycling, result in poor cycling stability. Herein, a series of Ca3(PO4)2- coated ultra-high nickel LiNi0.91Co0.06Al0.03O2 materials with different thicknesses (NCA@nCP) were prepared through a facile wet-chemistry strategy. Among them, NCA@1CP manifested specific discharge capacity of 204.8 mAh/g under 2.7-4.3 V at 1C (1C=200 mA/g), with a capacity retention rate of 91.5% after 100 cycles. Even after 300 cycles at 2C, the specific discharge capacity retained 153.4 mAh/g. Material characterization results further confirm that the coating shell inhibits the Li/Ni mixing, irreversible phase transformation and mechanical pulverization of the NCA@1CP, greatly improving the cycling stability. This work shows that the Ca3(PO4)2 coating strategy has great application potential in improving the lithium storage stability of ultra-high nickel cathode materials.