View fulltext

View fulltext

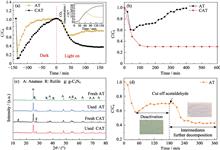

The photocatalysts deactivation is one of the major issues, which lowers the usefulness of photocatalytic oxidation technology for the removal of low content volatile organic compounds (VOCs). Here, we carried out a series of experiments to demonstrate that the photocatalysts stability could be significantly improved via coupling the oxide base semiconductors, i.e., TiO2 with 2D materials such as graphitic carbon nitride (g-C3N4). Initially, when Ag modified TiO2 (AT) was used for the gaseous acetaldehyde degradation, a robust deactivation was observed within 60 min. The AT catalyst completely lost its activity when the reaction time was extended to 400 min. On the contrary, the g-C3N4 modified AT (CAT) showed superior photocatalytic performance and improved stability (600 min). The in-situ FT-IR, PL, and photocurrent studies suggested that the accumulation of reaction intermediates in the case of AT fundamentally caused the deactivation. However, the g-C3N4 provided excessive adsorption sites for the reaction by-products which improved the stability. Additionally, the PL and ESR studies suggested that the existence of g-C3N4 improved the charge separation and production of reactive oxygen species, which facilitated the photodegradation of acetaldehyde and ultimate reaction products. This study realizes the usefulness of 2D materials for developing stable and visible light active photocatalysts for applications in sustainable VOC abatement technology.

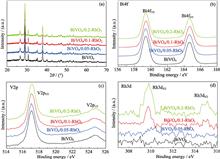

Bismuth vanadate is one of the most promising photoanodes for photoelectrocatalytic water splitting, however, its photoelectrocatalytic efficiency is still not ideal due to its sluggish kinetic reaction rate. The RhO2 cocatalyst was loaded on the BiVO4 thin film photoanode by impregnation method, and the photoelectrochenucal performance of the BiVO4 photoanode with different RhO2 loadings was studied. RhO2 with grain size of 10-25 nm was uniformly loaded on the BiVO4 film with grain size of 100-250 nm and thickness of 400 nm. The BiVO4 photoanode with 1.65% RhO2 (mass percent) showed the best comprehensive performance, of which the visible-light photocurrent density reached 3.81 mA·cm-2 under 1.23 V (vs. RHE) in 1.0 mol/L Na2SO3 (pH8.5) electrolyte, which was 10.58 times higher than that of bare BiVO4. In the absence of any sacrificial agent, the photoanodes produced hydrogen and oxygen at the same time at the ratio of close to 2 : 1, and the oxygen production rate was 8.22 µmol/(h·cm2). RhO2 loading effectively improved the surface water oxidation kinetics, so that photogenerated holes could undergo water oxidation reaction more quickly. Meanwhile, the photogenerated carrier recombination was inhibited, significantly improving the photoelectrocatalytic performance. In addition, since holes were more easily extracted from the surface of photoanode into electrolyte solution in the presence of RhO2 cocatalyst, reducing accumulation on the surface of the photoanode, the BiVO4/RhO2 (1.65%) photoanode achieved excellent stability for more than 10 h.

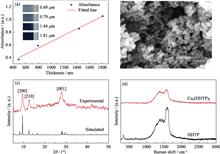

Room temperature ionic liquid shows wide electrochemical windows and good environmental stability, which is expected as an ideal electrolyte for electrochromic devices. However, the small crystal spacing of traditional electrochromic materials limits the diffusion of large ions in ionic liquid. Repeated deintercalation/ intercalation of large ions could also destroy the structure of traditional electrochromic materials, resulting in performance degradation. Metal-organic frameworks (MOFs) are topologically porous materials with a large intrinsic nano to microporous structure in crystalline, which are expected to provide channels for transporting large-sized ions in ionic liquids. In present work, triphenylene-based MOFs Cu3(HHTP)2 films were prepared on the surface of the conductive glass. Electrochemical and electrochromic behavior of Cu3(HHTP)2 films were studied in traditional propylene carbonate (PC)-based electrolyte and ionic liquid-based electrolytes. The results show that, compared with the traditional LiClO4/PC or NaClO4/PC electrolyte, Cu3(HHTP)2 film displays low contact resistance and high ion diffusion efficiency in the ionic liquid [EMIm]BF4 electrolyte. Switch speed of the electrochromic electrode is significantly improved with coloring time being reduced from 10.3 s to 8.0 s, and bleaching time being reduced from 23.6 s to 5.2 s. Meanwhile, Cu3(HHTP)2/[EMIm]BF4 electrochromic system also shows a larger light modulation range and coloring efficiency. This work demonstrates the potential of MOFs/ionic liquid electrochemical system in the field of electrochromic device.

Laser-driven white lighting sources have great potential for applications with super-high brightness, high directionality and long distance illumination, but are usually limited by their poor uniformity due to mismatch between blue laser light and phosphor converted light. In this work, a secondary phase of TiO2, BN, Al2O3 or SiO2 was introduced as scattering media in the Y3Al5O12 : Ce3+ (YAG) phosphor-in-glass (PiG) film to regulate the light path, where the optimum concentration of the secondary phase was determined, respectively. The images of illumination and speckle, angular distributions of luminance and color temperature, as well as optical properties of the white light produced by the different secondary phases based-YAG PiG films were investigated. The light uniformity in luminance and color temperature is greatly improved by introducing secondary phases, among which TiO2 is demonstrated as the best one as it has the largest relative reflective index. In addition, the YAG-TiO2 PiG film has the largest luminance saturation threshold of 20.12 W/mm2 and the highest luminous flux of 1056.6 lm under blue laser irradiation. This work paves an avenue to choose appropriate scattering media in PiG films for realizing more uniform and brighter laser-driven white lighting source.

Rare-earth (RE) ions doped perovskite-related fluorides are candidates for tunable optical materials. In this work, SrMgF4: xCe (x=0, 0.007, 0.013 and 0.035, in mole) powders were synthesized by a precipitation method. X-ray diffraction (XRD) patterns indicate that the obtained phosphors possess monoclinic superstructures. Electrovalence analysis confirms the existence of Ce3+/Ce4+ mixed valence. Two distinct fluorescence bands B and C were observed with different excitation wavelengths in the ultraviolet (UV) light region. Energy levels were modified strongly by the crystal field derived from monoclinic superstructures when the symmetry of Ce3+-polyhedra changed from high- to low- symmetry.

Preparation of ceramics by cold sintering process has attracted great attention, and some progress has been made in the preparation of BaTiO3 ceramics. In order to improve the performance of cold sintered BaTiO3 ceramics, BaTiO3 powder with good dispersion, particle size of 100 nm and tetragonality (crystal parameter c/a of 1.0085) was prepared by hydrothermal method, and then the powder was hydrothermally activated at 100 ℃ for 1 h with 0.1 mol/L acetic acid. Dense BaTiO3 ceramics were prepared by the Cold Sintering Process at 400 ℃, under a uniaxial pressure of 350 MPa for 1 h using 10% Ba(OH)2·8H2O (in mass) as flux. The as-prepared ceramic pellets were further annealed at 600 ℃ for 0.5 h. In the end, BaTiO3 ceramic sample obtained excellent characteristics with relative density of 96.62%, grain size of 180 nm, dielectric constant (εr) of 2836, and dielectric loss (tanδ) of 0.03. An amorphous titanium layer is formed on the surface of the highly active powder after acetic acid treatment, which effectively promotes the densification of ceramics, inhibits the formation of impurity phases and grain growth, improves the dielectric properties, greatly improves the dielectric dispersion phenomenon of cold sintered BaTiO3 ceramics, and realizes the low temperature cold sintering of BaTiO3 ceramics.

Color zirconia ceramics are widely used in electronics and decoration fields due to their bright colors, high refractive index, wear resistance, corrosion resistance, and non-toxicity to the human body. Cubic cerium doped 8% yttria mol percent stabilized zirconia (Ce-doped 8YSZ) nano-powder with average particle size of 15.9 nm was synthesized by co-precipitation method. Using the powder calcined at 800 ℃ for 4 h as starting material, red zirconia transparent ceramics with high optical transparency and high redness value were prepared by two-step sintering method. Influences of pre-sintering temperature on microstructure, in-line transmittance and color performance of the red Ce-doped 8YSZ ceramics were studied. As the pre-sintering temperature increases from 1200 ℃ to 1300 ℃, average grain size of the ceramics increases from 0.3 μm to 2.2 μm and the relative density increases from 87.2% to 97.1%. The Ce-doped 8YSZ ceramics pre-sintered at 1275 ℃ for 2 h and hot isostatic pressed (HIP) at 1700 ℃ for 3 h show the best in-line transmittance of 47.6% at 700 nm and the highest redness of 52.0.

Lithium-ion batteries are widely used as energy storage and dynamic power, while the capacity life of battery is one of the key factors affecting its further application. The electrochemical-mechanical multi-field coupling effect of the lithium-ion batteries during the cyclic charging and discharging process cause the damage accumulation for the electrode materials, thereby deteriorates the mechanical stability of the electrode materials, leading to multi-scale damage to the electrode materials, ultimately declining the battery life. In this study, the multi-scale failure behavior of LiNixCoyMnzO2 (NCM) cathode materials were summarized through our previous research, and the experimental and simulation analysis method for studying the damage of electrode material are introduced systematically, to provide reference for selecting damage analysis methods at different scales. In addition, the failure mechanisms of NCM cathode materials at the scale of active particles and electrode coating were studied in-depth based on combination of experimental and simulated analysis, including electrochemical experimental of lithium-ion batteries, extended finite element method (XFEM), linear matching method (LMM) framework. The research work provides important guidance for the mechanism analysis of multi-scale failure behavior and microstructure modification of electrode materials.

Spontaneous coagulation casting (SCC) is a novel in-situ ceramic forming method, not only universal for various ceramics but also working well at room temperature in air. Here presents the finding of SCC, involving an anion dispersant which acts as both dispersing and coagulating agent. Then, the difference between SCC and other in-situ coagulation methods in principle was elucidated. In SCC, particles participate in the formation of organic network which originates from hydrophobic interaction and hydrogen bonding among the dispersant molecular chains. The ceramic gel formed by SCC is a physical gel and possesses low density which is conducive to water transportation and stress relaxation during drying. In contrast, the one by conventional gelcasting is a chemical gel in which particles are fixed by a dense organic network. Based on the hydrophobic interaction, this review focuses on the design and synthesis of a series of SCC agents to meet the demand of forming dense and porous ceramics from particles with different sizes. That is, an anion dispersant is hydrophobically modified by a surfactant with a short or long chain. The obtained two agents are used for preparation of dense and porous ceramics, respectively. Progress of key technologies in this area including ceramic joining without interface, construction of grain orientation, drying, preparation of dense ceramics and porous ceramics, by SCC is summarized. Typically, alumina disc with a diameter up to 1010 nm and alumina parts with complicated shape such as dome and guide are shown. Future development of SCC is also proposed to enable SCC is a more universal forming technology for advanced ceramics with a large and/or complicated dimension.

Silicon carbide fiber reinforced silicon carbide (SiCf/SiC) composites have become the preferred candidate for structural applications in advanced nuclear energy systems, because of their low neutron toxicity, neutron irradiation tolerance and high-temperature oxidation resistance. In recent years, both academia and industry either domestic or abroad have carried out a lot of researches on SiCf/SiC composites for nuclear application, and numerous important achievements have been made. This paper summarized and analysed some critical directions of SiCf/SiC composites for nuclear applications, including nuclear-grade SiC fibers, fibre/matrix interfaces, composite processing, modeling and simulation, corrosion behavior and surface protection, joining technology, as well as radiation damage. The key issues and potential solutions of SiCf/SiC composites for nuclear applications have been pointed out in account to the requirements, anticipating to be beneficial to promoting further researches and final applications.

Special ceramics are widely used in aerospace, electronics, information, new energy, machinery, chemical industry, and other emerging industries. Their high temperature preparation process is still dominated by traditional gas kilns and electric heating furnaces with high carbon emissions and high energy consumption. The energy conservation-emission reduction situation is grim at present. Therefore, China is facing great pressure to achieve ‘double carbon’ goal, badly needing research and promotion of clean and efficient heating technology. Microwave heating uses the dielectric loss of the material itself to absorb microwave and convert electromagnetic energy into heat energy at molecular level. In this way, heat is generated simultaneously both inside and outside the whole material, leading the temperature gradient very low in the whole material. In addition to the volumetric heating, selective heating, power redistribution, thermal upheaval, and microwave plasma effect are important characteristics of microwave sintering. Microwave heating has the advantages of energy conservation, environmental protection, improved product performance and reduced combustion carbon emissions. There are many reports on microwave synthesis of various oxides, carbides, nitrides ceramic powders, and microwave sintering ceramic composites domestic and abroad. In this paper, the basic theories of microwave sintering and microwave mixed sintering are reviewed firstly, and then the latest research progress on preparation of ceramic powders by microwave heating and ceramic materials preparation by microwave sintering is introduced. Finally, microwave heating used in sintering of ceramic engineering products is introduced, which shows the superiority of microwave sintering. The key problems and the future development direction of special ceramics prepared by microwave sintering are also proposed.

Porous silicon nitride (Si3N4) ceramics can be widely used in various fields, such as sound and shock absorption, filtration and so on, due to its high porosity and outstanding properties of ceramics. However, conventional preparation methods, such as gas-pressure/pressureless sintering, sintering reaction-bonded sintering and carbothermal reduction sintering, perform long sintering time, high energy consumption and high equipment requirements, which makes the preparation of porous Si3N4 ceramics expensive. Therefore, it is of great importance to explore a rapid and low-cost preparation method. In recent years, the direct preparation of porous Si3N4 ceramics by self-propagating high temperature synthesis (SHS) has showed great potential of which the heat released from the nitridation of Si powder could be used for the in-situ sintering of porous Si3N4 ceramics. In present paper, researches relating to the initiation of the SHS reaction, and microstructural evolution, mechanical properties, and reliability of the fabricated Si3N4 ceramics are summerized systematically. Porous Si3N4 ceramics with complete nitridation, excellent grain morphology and outstanding mechanical properties and reliability are obtained by adjusting raw materials and process parameters. Furthermore, the relationship between properties of grain boundary phase and high-temperature mechanical properties of SHS-fabricated porous Si3N4 ceramics is reviewed. Finally, the development direction of the self-propagating high temperature synthesis of porous Si3N4 ceramics is prospected.