View fulltext

View fulltext

Microwave composite substrates are the key materials in the fields of aerospace, electronic countermeasure and 5G communication, etc., as they have combined high toughness of resin matrix and excellent dielectric and thermal properties of ceramic filler. Here, a new category of microwave composite substrates with polyphenylene oxide (PPO) as matrix and Ca0.7La0.2TiO3 (CLT) ceramic as filler were prepared by a novel technology which combined screw granulating and injection molding. Its microstructure, microwave dielectric properties, thermal and mechanical properties of the substrates were characterized. The results show that such microwave composite substrates prepared by this technology maintain homogeneous composition and compact structure. As volume fraction of CLT ceramic increases from 0 to 50%, the dielectric constant of the substrate increases from 2.65 to 12.81 and the dielectric loss decreases from 3.5×10 -3 to 2.0×10 -3 (@10GHz). Meanwhile, coefficient of thermal expansion (CTE) of the substrate significantly decreases from 7.64×10 -5 ℃ -1 to 1.49×10 -5 ℃ -1 and the thermal conductivity increases from 0.19 W·m -1·K -1 to 0.55 W·m -1·K -1. Additionally, bending strength of the substrate is improved from 97.9 MPa to 128.7 MPa. The PPO/CLT composite substrate filling with 40% CLT (in volume) ceramic exhibits excellent properties: εr=10.27, tanδ=2.0×10 -3(@10GHz), α=2.91×10 -5/℃, λ=0.47 W·m -1·K -1, σs=128.7 MPa, so that it has good application prospects in aerospace, electronic countermeasure, 5G communication and other fields.

0.96NaNbO3-0.04CaZrO3(NNCZ) ceramic shows stable double hysteresis loops at room temperature, but the property of energy density, energy storage efficiency and breakdown strength of NNCZ are terrible, which limit NNCZ to be used as energy storage materials. In this work, Fe2O3 was chosen to modify the energy storage property of NNCZ. (0.96NaNbO3-0.04CaZrO3)-xFe2O3 (NNCZ-xFe) antiferroelectric ceramics were prepared by traditional solid reaction method. The phase, morphology, dielectric property and energy storage property of NNCZ-xFe were characterized. The results indicated that the crystal structures of NNCZ-xFe ceramics were pure perovskite structure. The sintering temperature of NNCZ ceramic was decreased with addition of Fe2O3. With the increase of Fe2O3 content, the grain size of NNCZ-xFe were decreased firstly and then raised. The NNCZ-0.02Fe ceramic obtained the smallest grain size (5.04 μm) and the best energy storage property. The breakdown strength of NNCZ-0.02Fe was 230 kV/cm at room temperature (RT). The recoverable energy density and energy storage efficiency before breakdown were 1.57 J/cm 3and 55.74% respectively. At 125 ℃ and 180 kV/cm, the energy density of NNCZ- 0.02Fe was 4.53 J/cm 3. Fe2O3 doping decreased the sintering temperature of NNCZ ceramics, reduced the the migration rate of oxygen vacancies and inhibited the growth of grains. At the same time, it reduced the dielectric loss and improved the breakdown strength. The oxygen vacancies pinning made antiferroelectric phase switch to ferroelectric phase harder, avoided appearance dumbbell-shaped double hysteresis loops, so the energy storage efficiency was improved. This research shows that NNCZ-xFe has a good potential application in the field of dielectric energy storage.

The high-frequency ultrasonic technology has been widely used for the fine structures medical imaging of skin, eye and vessel as its high spatial resolution. 1-3 piezocomposite plays an important part in the high frequency transducer owing to the excellent electromechanical coupling properties of this material even at high frequency. However, its industrial applications were limited by the inefficient fabrication methods and expensive equipment, such as mechanical cutting-filling and plasma/laser etching. In this work, a low-cost and novel soft mold method was developed to fabricate 1-3 piezoelectric composites with high electromechanical coupling coefficient kt for high frequency ultrasound transducers. The process of soft mold filling, hot-pressed sintering PZT pillars and epoxy curing was ruly carried out. Then, a series of samples with different thicknesses were fabricated and characterized. It demonstrates that the fabricated PZT pillars with pure rhombohedral phase are homogeneous. Besides, the length to diameter ratio of sintered pillars is 10 : 1 and the kt of the 1-3 piezocomposite reaches as high as 64% for the 30-50 MHz high frequency transducer. The result indicates that the soft mold method is an economical and effective way to fabricate the 1-3 piezoelectric composites for medical and biological imaging in high frequency ultrasound applications.

Zr and Ca co-doped brium titanate (BCTZ) based ceramics have attracted much attention due to their excellent dielectric and piezoelectric properties, which are potential candidates for lead-free piezoelectric materials. However, the piezoelectric property of BCTZ-based ceramics are still lower than that of commercial lead-based ceramics. Therefore, Sn elements are doped in (Ba0.85Ca0.15)(Ti0.9Zr0.1-xSnx)O3 (x = 0.02-0.07) ceramics to improve their piezoelectric property in this work. First, all ceramics exhibit a pure perovskite structure without any secondary phase. Furthermore, orthorhombic and tetragonal phases coexist at room temperature for all counterparts. Second, all ceramics display a dense microstructure. And the grain size gradually increases with Sn content increasing. The crystal structure of x=0.04 ceramic locates in morphotropic phase boundary. Meanwhile, the x=0.04 ceramic exhibits the most dense microstructure. Hence, x=0.04 ceramic has the best piezoelectric property with d33 = 590 pC•N -1, kp = 52.2%, tanδ = 0.016, ε T33= 5372, d *33= 734 pm•V -1, and IR = 57.8 GΩ•cm. This work demonstrates that the Sn-doped BCZT based lead-free piezoelectric ceramics could be applied in transducers, electromechanical sensors and actuators.

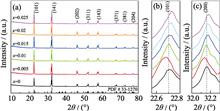

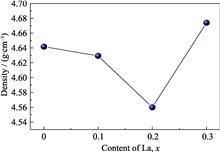

Potassium sodium niobate (K0.5Na0.5NbO3, KNN) based ceramics can be widely used for pulsed power systems due to their fast charge-discharge rate, high transparency, wide range of working temperature, and long cycle life. Improving the electrical and optical property of KNN-based ceramics through modification is a research hotspot in this field. 0.825(K0.5Na0.5)NbO3-0.175Sr1-3x/2Lax(Sc0.5Nb0.5)O3 (x=0, 0.1, 0.2, 0.3) (0.825KNN- 0.175SLSN) ceramics were synthesized by solid state method. The effect of La2O3 doping on the phase structure, microstructure, optical property, dielectric property, ferroelectric property and energy storage property of the ceramic was studied. The results indicated that the structure of 0.825KNN-0.175SLSN ceramics is pseudo-cubic phase with high symmetry. With increment of La2O3 content, the average grain size of 0.825KNN-0.175SLSN ceramics decreased, and the phase transition temperature (Tm) and saturation polarization intensity (Pmax) increased and then decreased. 0.825KNN-0.175SLSN ceramics exhibit excellent transparency at x=0.3, the transmittance in the visible wavelength (780 nm) and near-infrared wavelength (1200 nm) ranges reaches 65.2% and 71.5%, respectively. The dielectric breakdown strength of 310 kV/cm and a recoverable energy density of 1.85 J/cm 3 are achieved at x=0.3.

Two-dimensional (2D) monolayer MoSi2N4 has attracted wide attention due to its excellent carrier transport capacity and chemical stability. However, the relationship between its photoelectric properties and applied plane strain has not been thoroughly explored. The effect of plane strain on band structures and photoelectric properties of 2D monolayer MoSi2N4 is revealed by the plane-wave ultrasoft pseudopotentials. The results show that the monolayer MoSi2N4 is an indirect band gap semiconductor. Its top of valance band is dominated by Mo4d orbitals and partly contributed by N2p orbitals, while its bottom of conduction band is mainly contributed by Mo4d orbitals. Under tensile strain, band gap of monolayer MoSi2N4 narrows gradually and effective mass of photogenerated carriers decreases continuously. Under compressive strain, the band gap widens gradually and the effective mass increases slowly. It is worth noting that a compressive strain (ε=-2.8%) results in transition form indirect to direct band gap. Optical absorption of monolayer MoSi2N4 exhibits obvious anisotropy, which edge shifts in different degree under the plane strain, effectively expanding the spectral response range of the system and beneficial to the photoelectric properties. These results provide a theoretical guidance for further research on the application of 2D monolayer MoSi2N4 in the field of new tunable nano optoelectronic devices.

Developing a highly efficient and stable photocatalyst or co-catalyst is one of the important topics in the field of photocatalysis research. In this study, graphene oxide, cobalt chloride and 2-methylimidazole were used as precursors to prepare Co5.47N-loaded nitrogen-doped reduced graphene oxide (Co5.47N/N-rGO) co- catalyst by combining liquid phase method and nitridation in flowing NH3 where Co5.47N with a crystallite size of 10~20 nm was highly dispersed over N-rGO surface. The Co5.47N/N-rGO co-catalyst significantly improves the hydrogen evolution performance of commercial nano TiO2 (P25). When the mass percent of Co5.47N/N-rGO was 25%, the hydrogen evolution rate of the obtained sample reached 11.71 mmol·h -1·g -1, which was 90 times higher than that of pure P25 and similar to that loaded noble metal Pt (11.88 mmol·h -1·g -1). Furthermore, the catalyst also has good stability. The research provides a new idea for the future development of efficient non-precious metal co-catalysts.

Oxygen evolution reaction (OER) plays an important role in solving energy shortage and environmental problems, but it requires a huge overpotential to overcome the slow kinetic barriers, so the development of high- efficiency electrocatalysts has become an indispensable step. In this work, the performance of α-MnO2(001) and Mo doped α-MnO2(001) electrocatalytic oxygen evolution reaction were studied by using density functional theory. Gibbs free energy, density of states and differential charge density were calculated according to the reaction path. The research results show that Mo doping can effectively modulate the electronic structure of α-MnO2(001) surface, improve desorption and adsorption capacity between intermediates and the catalyst, and provide more electrons for OER. Gibbs free energy calculation results indicate that the formation of O2 from *OOH is the rate-determining step for OER in the Mo doped α-MnO2(001) system. Mo doping reduces the overpotential to 1.01 V, which presents a good catalytic performance for oxygen evolution.

Formic acid (FA) is considered as a new type of hydrogen storage material with great application prospect due to its high hydrogen content and easy recharging as a liquid. Seeking high efficiency catalysts to solve the problem of slow reaction kinetics of hydrogen evolution from FA is vital. In this work, polyethyleneimine modified graphene (PEI-rGO) was used as the catalyst substrate, and PEI-rGO supported AuPd nanocomposite material (Au0.3Pd0.7/PEI-rGO) was prepared by wet chemical method. The Au0.3Pd0.7/PEI-rGO catalyst exhibits remarkable activity for the hydrogen generation from FA, affording an unprecedented turnover frequency (TOF) of 2357.5 molH2∙ molcatalyst-1∙h -1 without any additives, which is superior to most heterogeneous catalysts under similar reaction conditions. Its excellent catalytic performance is attributed to the strong interaction between PEI-rGO substrate and AuPd nanoparticles, which regulates the size, dispersion and electronic structure of metal active components. Furthermore, the recycle test result shows that the catalyst has good stability.

Metal nanomaterials as mimic enzyme have been widely used for biosensor and catalysis due to their high stability and low cost. Here, [1-methyl-3-ethylimidazole][dicyandiamide] ionic liquid ([EMIM][DCA]) reacted with ruthenium chloride to form [EMIM]3[Ru(DCA)6] ionic liquid. Silk was dissolved in the above ionic liquid and then carbonized at high temperature to obtain Ru-biomass carbon composite. The results show that Ru-biomass carbon offers excellent dispersion, small Ru nanoparticles with an average diameter of 7.5 nm which were uniformly dispersed on the surface of carbon sheets, and high oxidase-like activity. Based on the inhibition of chlorpyrifos on catalytic activity of Ru-biomass carbon, a method was established for colorimetric determination of chlorpyrifos. Chlorpyrifos obviously inhibits the catalytic activity of Ru-biochar carbon, leading to a reduced absorbance of blue product. When the concentration of chlorpyrifos was in the range from 10 to 80 ng/mL, the peak absorbance decreases linearly with the increase of chlorpyrifos concentration, giving a detection limit of about 6.5 ng/mL. The as-proposed method provides higher sensitivity and stability compared with present methods, and has successfully applied to detection of chlorpyrifos in peach samples.

LaNiO3 (LNO), as a promising material in ferroelectric super lattices, super conductive heterostructures and catalysts has recently attracted great interest. Herein, a facile and low-cost polymer assisted deposition (PAD) method is established to prepare epitaxial LNO thin films on (001) orientated SrTiO3 (STO) with excellent conductivity. Various structural and electrical characterizations of the film were investigated. The film has good crystallinity with a full-width at half-maximum value of 0.38° from the rocking curve for the (002) reflection. High resolution XRD φ-scans further confirmed the heteroepitaxial growth of LNO film on STO substrate. There are four peaks separated by 90°, showing that the LNO thin film is cubic-on-cubic grown on STO substrate. In-situ high temperature XRD measurement showed epitaxial growth of LNO thin film on STO substrate. Metal cations could be released orderly on the monocrystalline substrate and epitaxial crystallization occurs after decomposition of polymer. XPS results indicated that LaNiO3 thin film fabricated by PAD was stoichiometric without oxygen vacancy. The atomic force microscopy analysis showed that the smooth surface with root-mean-square surface roughness was 0.67 nm. The resistivity as functions of temperature revealed that it has good conductivity from 10 K to 300 K. All results demonstrate that the LaNiO3 thin films deposited by PAD have better comprehensive performance, indicating that PAD method has great potential for preparing epitaxial functional thin film materials.

Ag-based electrical contact plays a key role in low-voltage switches, which is intended to substitute the traditional and toxical “universal” contact of Ag/CdO. As a new kind of two-dimensional carbide material with good electrical conductivity and thermal conductivity, Ti3C2Tx, a representative of MXenes has showed exceptional potential in various fields, including being the reinforcement phase in electrical contact materials to substitute for the toxic CdO. In this work, we successfully prepared Ag/Ti3C2Tx composite by powder metallurgy. Phase and microstructure of the Ti3C2Tx and Ti3AlC2 were characterized, and their properties, such as electrical resistivity, microhardness, machinability, tensile strength, and anti-arc erosion performance were investigated and compared. The Ag/Ti3C2Tx has a resistivity of 30×10 -3 μΩ·m, 29% lower than that of Ag/Ti3AlC2 (42×10 -3 μΩ·m) and excellent machinability with intermediate microhardness (64 HV), showing broad application prospect as non-toxic electrical contact materials. Its improved conductivity is mainly attributed to the metallicity of Ti3C2Tx itself, the microstructural features, endowed by the deformability of Ti3C2Tx. However, the tensile strength (32.77 MPa) of Ag/Ti3C2Tx is inferior to that of Ag/Ti3AlC2 (145.52 MPa) due to lack of Al-Ag interdiffusion. The anti-arc erosion performance of Ag/Ti3C2Tx is also unmatchable with Ag/Ti3AlC2 due to absence of Al layer. Although the arc erosion resistance of Ag/Ti3C2Tx needs to be further improved uptill now, the significantly improved electrical conductivity makes it a potential substitute of current toxic Ag/CdO material. All results of this work provide an exploration direction for developing new environmentally friendly electrical contact material in the future.

Si3N4-BN-SiC composites present desirable potential for engineering applications because of their improved mechanical properties and oxidation resistance. In present work, Si3N4-BN-SiC composites were successfully fabricated by combustion synthesis using Si, Si3N4 diluent, B4C, and Y2O3 as initial powders. BN and SiC were in situ introduced into Si3N4 ceramics by the reaction between Si, B4C, and N2 gas. The obtained Si3N4-BN-SiC composites were composed of elongated β-Si3N4 matrix and hollow spherical composites. The formation mechanism of the hollow spherical microstructure was investigated. The results show that the generated SiC and BN particles and glass phase cover on the raw materials, and hollow spherical microstructure is formed when raw particles are depleted. Furthermore, the impacts of B4C content on the mechanical properties of Si3N4-BN-SiC composites were investigated in detail. The in-situ introduction of BN and SiC is beneficial to improving mechanical properties of the composites to some extent. Finally, Si3N4-BN-SiC composites with bending strength of 28-144 MPa, fracture toughness of 0.6-2.3 MPa·m 1/2, Young's modulus of 17.4-54.5 GPa, and porosity of 37.7%-51.8% were obtained for the samples with 0-20% (in mass) B4C addition.

Silicon carbide nanowires (SiCNWs) possess excellent electromagnetic absorption performance and a three-dimensional (3D) network structure is beneficial to the multiple reflection and absorption of electromagnetic waves (EMWs). The 3D staggered SiCNWs network preforms with a volume fraction of 20% was realized by vacuum filtration method. And then the PyC interphase and SiC matrix were prepared through chemical vapor infiltration (CVI) process, and the densified SiCNWs/SiC ceramic matrix composites were obtained through CVI and precursor impregnation pyrolysis (PIP) process. Methane (CH4) and trichloromethylsilane (MTS) were selected as gaseous precursor of the PyC and SiC, respectively. With increase of deposited PyC from 0 to 29.5%, the electromagnetic interference (EMI) shielding efficiency (SE) of the porous SiCNWs increases from 9.2 dB to 64.1 dB in 8-12 GHz (X-band). The densified SiCNWs/SiC ceramic matrix composites with a mass gain of about 13% of PyC interphase present an average EMI SE of 37.8 dB in X-band. The achieved EMI shielding properties suggested that the potential application of the SiCNWs/SiC ceramic matrix composites may be a promising new-generation EMI shielding material.

Flash sintering is an electric field assisted sintering technology which has attracted much attention in recent years. This review introduces its origin, development, and basic characteristics. In the study of flash incubation and initiation process, the nonlinear conductivity characteristics and electrochemical blackening phenomenon are narrated, and the defect mechanism dominated by oxygen vacancy is recounted. As for rapid densification during flash sintering, it is proposed that the generation and movement of defects caused by electric field produce Coulomb force between powder particles, which is conducive to density in the early stage of flash sintering. Meanwhile, the densification process is accompanied by the rapid movement of metal cations. In terms of grain growth and microstructure evolution during the flash sintering, the sample temperature is asymmetrically distributed along the current direction, and the internal grain boundary mobility in the sample is significantly improved. During this stage, electrochemical defects exert a significant impact on the microstructure. Based on the above researches, we developed ceramic flash joining technology by using phenomenon of low-temperature rapid mass transfer under electric field, and realized rapid joining between similar kind of ceramics/ceramics, ceramics/metals, and even dissimilar ceramics/ceramics. A new ultrafast ceramic synthesis technology by flash sintering was developed, which not only realized the rapid synthesis of typical oxide ceramics, but also realized the rapid synthesis of high entropy ceramics and oxide ceramics with eutectic morphology. An electroplastic forming technology of oxide ceramics was developed, and a rapid tensile and bending deformation of zirconia ceramics at low temperature and low stress was preliminarily realized. Finally, this review summarizes the challenges in the field of flash sintering mechanism, and looks forward to the development direction of flash sintering from two aspects of Joule heating effect and nonthermal effect, aiming to be beneficial to the development of flash sintering technology in China.

As green rechargeable batteries, lithium-ion batteries feature high energy and power density. However, commonly-used electrolytes, organic compounds, in commercially available lithium-ion batteries are flammable and toxic, which leaves them at the risk of combustion and explosion when being overcharged or short-circuited. In order to solve this problem, much attention has been paid to lithium-ion batteries with aqueous electrolytes, which take low-toxicity and high safety as the prominent advantages. The working voltage, 1.5-2.0 V, indicates their usage mainly in the field of energy storage. Considering the hydrogen and oxygen evolution, conventional anode materials used in commercially available lithium-ion batteries are inconformity for water-based lithium-ion batteries. Therefore, the key to the development of aqueous lithium-ion batteries lies in the selection of anodes. The anode material, LiTi2(PO4)3, has drawn the attention of researchers due to its advantages such as three-dimensional channel, and appropriate lithium-ion intercalation potential. The synthesis methods of LiTi2(PO4)3 mainly include high temperature solid-phase calcination, Sol-Gel methods and hydrothermal reaction, etc. To further improve the electrochemical performance of LiTi2(PO4)3, strategies can be used such as particle nanocrystallization, morphology control, element doping, and carbon-coating, etc. This review focuses on the synthesis and modification of LiTi2(PO4)3, as well as related research progress. At last, the future development of LiTi2(PO4)3 as anode material for lithium-ion battery is properly prospected.