View fulltext

View fulltext

This study aims to address the technical blockade of programmable control systems, which are the core control component of manufacturing equipment, and to break through complex technical systems for the integration of mechanics, electronics, computer science, bus communications, and other disciplines. In addition, it responds to the "Made in China 2025" and "Industrial Strong Foundation Project" independent and controllable development goals. This study analyzes the development process and technical system of a programmable control system and proposes a composition scheme based on a real-time Ethernet field bus. The working principle and key technologies of the field bus, master-slave hardware, software integrated development environment, man-machine configuration software, and other components in the composition scheme are explained. Furthermore, various research methods and the development of a technology ecology are proposed to achieve independent controllability. The solutions for key technologies provide a reference for the safe and stable development of the Chinese equipment manufacturing industry.

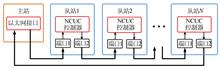

In a bus-based control system, the transmission rate and synchronization accuracy of the fieldbus are key factors affecting the speed and accuracy of multi-axis collaborative machining tasks. To satisfy the performance requirements of high-speed and high-precision manufacturing equipment, the transmission rate and synchronization accuracy of the control system must be optimized and the information security of industrial communication must be ensured. Based on domestic FPGA chip, a general Ethernet interface circuit that conforms to the IEEE802.3 specification is designed and a linear cascaded network topology is constructed in this study. Considering the channel transmission principle of industrial control process and service data, a data transmission method for channel mapping is proposed, improving the bus efficiency. A distributed clock synchronization mechanism is used to calculate the network transmission delay and time offset using timestamps, and synchronization control is achieved by compensating for the bus controller. Experimental results show that the designed high-precision synchronous real-time Ethernet bus controller can achieve a minimum communication period of 250 μs in a 100 Mb/s Ethernet link, and that the synchronization accuracy of each node in the network is less than 50 ns, which corresponds to the international advanced level.

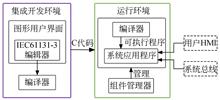

The master station programming tool is an important component of the visual design, download, and operation of the whole logic function and motion control function programs of a programmable control system. To break the foreign monopoly on industrial control software platforms, the development of a safe and reliable master station programming tool serving an autonomously controllable, programmable, control system, is paramount. This paper investigates the design method for each component of the master station programming tool chain. First, according to the working principle of an open-source integrated development environment (IDE), a software architecture for the master station programming tool based on IEC61131-3 is proposed. Then, the plug-ins for bus configuration and data access in the IDE are designed from the perspective of generating code integrity, and the architecture and components of Runtime executed by the master code are also designed, forming a fully functional programming tool chain. Finally, taking two basic safety functions as examples, the integrated development method of the IEC61800-5-2 functional safety basic library is analyzed. The experimental results show that the master station programming tool designed in this paper has functions such as visual programming, downloading, and running, and it meets the basic program development requirements for autonomously controllable, programmable, control systems.

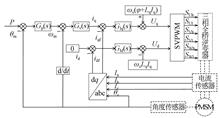

To avoid safety accidents caused by the unexpected movement of mechanical parts during equipment manufacturing, this paper investigates the safety integrated design method of the servo drive module according to the IEC61800-5-2 standard. First, the principle of servo drive module is clarified by analyzing the mathematical model, hardware structure, and functional architecture of the servo drive. According to the principle, the failure mechanism, failure mode, and effect of failure on the system are discussed. The safe operation interval based on parameter constraint is established, which can actively monitor the dangerous failure of the servo drive module. Then, by analyzing the characteristics of 17 safety functions suggested by IEC61800-5-2, the architecture of safety related system is designed, and a method for safety function integration based on object dictionary is proposed, which can realize the configuration of safety functions according to the specific security requirements. Finally, the experimental platform is built, and the typical safe logic is designed to verify the safety integration method. The experimental results show that the proposed functional safety integration method can effectively implement the IEC61800-5-2 recommended safety functions through configuration, and it meets the requirements of the servo drive module to generalize the safety functions.

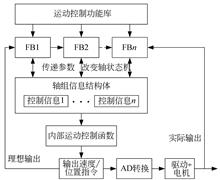

A motion control function library comprises a set of standard functional blocks integrated in a programmable integrated environment, which is vital to the rapid development of reconfigurable PAC systems. To solve the problems associated with the rapid development of functional blocks and the standardized development of control systems, the development methods and key technologies of functional blocks are investigated in this study; In addition, a motion control function library architecture based on the PLC open specification and its rapid development method are proposed. First, the servo control principle of classical electromechanical equipment is investigated and analyzed, and a series of motion control function libraries are developed via domestic programming and development tools. Subsequently, based on the idea of software-defined machines, a motion control system of mechanical and electrical equipment is constructed via graphical programming and then verified on a high-precision rotating double prism. Experimental results show that the developed functional block can complete the target motion and that the highest interpolation accuracy achievable by the autonomous controllable system is 0.3 mm. Therefore, the proposed development method for functional blocks and function library architectures can satisfy the control requirements of most electromechanical devices.

To achieve an optimized laser-assisted ultra-precision cutting process for monocrystalline silicon and to explore the surface characteristics of monocrystalline silicon components after cutting, the in-situ laser-assisted single-point diamond cutting process parameters of monocrystalline silicon are optimized by the orthogonal experimental method. Various parameters of monocrystalline silicon are measured and analyzed, such as surface quality and accuracy, residual stress, and optical transmittance. Through the variance analysis of the surface roughness and signal-to-noise ratio analysis of the orthogonal experimental data, the optimized process parameters are obtained as follows: spindle speed=1 500 r/min, feed rate=5 mm/min, cutting depth=3 μm, and laser power=4.5 W. The surface roughness and accuracy PV are 2.74 nm and 0.52 μm, respectively, for the 165 mm monocrystalline silicon aspheric optical lens processed with the above process parameters. After the laser-assisted cutting, there is residual stress of (-1 760.8±362.1) MPa on the monocrystalline silicon. The machined monocrystalline silicon's refractive index is 3.43, and the transmittance before and after the coating is 55% and 98%, respectively, in the common 3–5 μm mid-infrared band. The above research results show that laser-assisted ultra-precision machining technology can be used as the semi or final finishing process to improve the manufacturing efficiency of complex surface monocrystalline silicon lenses.

The use of shower ion beam etching for the "lateral extraction" of multiple diabolo-shaped metallic nanopatterns was proposed, enabling the direct and rapid fabrication of multiple metallic nanogap structures. In a typical process, after the nanostructured resist patterns were defined by electron beam lithography, traditional metal deposition and wet lift-off were performed to transfer the resist pattern to a diabolo-shaped metallic nanostructure. The metallic patterns were then immediately trimmed using shower ion beam etching. The gap distance between two isolated nano-antennas could be narrowed to less than 10 nm by precisely controlling the etching time. In addition, combined with the hydrogen silsesquioxane (HSQ)-based negative-resist patterning process, free-standing metallic nanogaps atop HSQ nano-templates were obtained. The morphological evolution of nanostructures during the etching process was characterized. Systematic experiments and numerical simulations were conducted to verify the advantages of suspended metallic nanogap structures for surface-enhanced Raman scattering. The proposed process provides a new means for the one-time formation of multiple ultra-small metallic nanogap structures. It has promising application prospects in the low-cost and high-efficiency preparation of large-area Raman sensing substrates.

To quantitatively describe the effect of out-of-focused-plane displacements on the in-focused-plane micro-vision motion-tracking accuracy, a method based on an optical microscope, an industrial camera, and a spatial nano-positioning stage is proposed in this work. First, the formation mechanism of out-of-focused-plane displacements was analyzed. The variance function was employed to evaluate the sharpness of the image and search for the best-focused plane. The searched plane was used as the baseline to calculate out-of-focused-plane displacements. Second, a spatial nano-positioning stage was designed with multiple degrees of freedom. The end-effector served as the target to be tracked by the micro-vision. When generating in-focused-plane displacements, controllable and measurable out-of-focused-plane displacements were also produced simultaneously and synchronously by the end-effector. Third, the gray-value-based template matching approach was selected and combined with the region-of-interest method. This approach served as a representative micro-vision motion-tracking algorithm. Finally, the prototype of the nano-positioning stage was fabricated, and the micro-vision motion-tracking experimental system was constructed. Capacitive sensors were employed as evaluation tools. The degradation values of the micro-vision motion-tracking accuracy when excited by different out-of-focused-plane displacements were quantified. The experimental results indicate that out-of-focused-plane displacements directly contribute to accuracy degradation. The displacements and degradation were significantly correlated. The area of the proposed viewing field was 76.1 μm×63.7 μm, the sampling frequency was 15 Hz, and the gray-value-based template-matching approach was employed. When the out-of-focused-plane displacement reached (7.7±2.5) μm or larger, the micro-vision system was rendered inoperable.

Thermal deformation is the main factor affecting the machining accuracy of grinding machines, which severely limits further improvements in the accuracy of machine tools. However, only a few studies have investigated thermal error prediction, and the prediction accuracy has been low. Therefore, this paper proposes a method to predict the thermal error of grinding machine spindles based on the heat conduction theory and a convolutional neural network. First, according to the heat conduction theory, the mapping relationship between the thermal variables and the temperature difference between the surface of the main axis of Chu and the external environment is deduced, revealing the thermal deformation nature of the materials. Second, a neural network model for thermal error prediction with temperature difference as the input and thermal deformation of the main shaft as the output is established. The model has four neural network layers corresponding to temperature difference, thermal energy increment, time variable, and thermal deformation. The back-propagation algorithm is then used to train the prediction model and calculate the model parameters. Finally, based on the SINUMERIK 840D CNC controller, a set of thermal error compensation systems for grinding machine spindles are developed and verified using a CNC grinding machine. The results show that the machining accuracy of the grinder is improved by 41.7% following thermal error compensation for the spindle, thus confirming the validity and feasibility of the spindle thermal error prediction model proposed in this paper.

In this study, a high-frame-frequency camera system is investigated to closely capture the collision process of a high-speed moving target. As debris from the collision may get stuck to the front of the lens, a protective window assembly is considered. A thermal conduction device was also investigated because the temperature of an FPGA installed in the imaging unit is too high, with a maximum temperature of 70 ℃. A method for continuous photography with seven image units under the control of a sequence pulse was proposed,and the camera system achieved high frame-frequency imaging of 50,000 fps. The protective window assembly included three sets of self-locking protective window glasses that move automatically. A worm gear was utilized to realize a large transmission ratio and self-locking function, and a Hall sensor was used to report the position of the protection window in real time. The middle part of the heat conduction device comprised flexible graphite plate with high thermal conductivity. Thus, the heat of the FPGA was transmitted effectively to the shell, and the problem of over-positioning of rigid heat conduction devices was solved during the installation and adjustment of the device. Vibration and heat tests were carried out on the assembled model camera. During and after the tests, the self-locking,movement and switching of the protective window component function properly, the camera works normally, and the measured frame rate is 50050 frames/s. Hence, the camera system meets the requirements for clearly recording high-speed collisions, and provides a certain protection ability as well as adaptability to different thermal environments.

The analog/digital acquisition module for intermediate frequency (IF) signal acquisition is the fundamental component of frequency-modulated continuous-wave (FMCW) lidar. Parameters such as the signal-to-noise ratio (SNR), signal-to-noise and distortion ratio (SINAD), and spurious-free dynamic range are major indicators of the alternating current characteristics of the data acquisition signal chain and directly determine the key indicators of FMCW lidar, including the detection range and ranging accuracy. First, this study designed an IF signal acquisition module for FMCW lidar, where the obtained SNR and SINAD were 49.13 dB and 48.90 dB, respectively. Second, the study investigated the noise characteristics of FMCW lidar, identified the system noise source as the phase noise of the sampling clock, and improved the SNR and SINAD by 11.38 dB and 11.32 dB, respectively, by introducing digital filters, which theoretically increased the detection range of FMCW lidar by 3.7 times. System noise can be reduced by using cosmetic clock chips, and the SNR can be improved by 8.65 dB. Finally, an optical phased-array FMCW lidar system was built to verify the effectiveness of the data sampling module and to conduct 40-m range distance detection under a maximum measurement error of 7.7 cm. The study determined that the FMCW lidar’s maximum detection range was 133.67 m.

The optical fiber array collimator is a major component in optical fiber communication systems, and its development is gradually moving toward array and integration. The traditional method of constructing a fiber array collimator is based on single-fixed and graded index lenses. It has disadvantages, such as difficulties in integrating and expanding the number of array elements and a complex packaging process. In this paper, a method of fabricating a fiber array collimator based on a plano-convex microlens array is proposed. The method utilizes the advantages of easy arraying of optical microlenses and good uniformity of array element characteristics. The theories of Gaussian and matrix optics were applied to analyze and simulate the collimation characteristics and determine the relevant design parameters of the fiber array collimator. A fiber array collimator with an array pitch of 250 μm is fabricated in this study. The far-field divergence angle is the main performance parameter measured using the far-field spot method. The measurement uncertainty is analyzed and evaluated using the Monte Carlo method. The measured values of far-field divergence angles of each channel in the fiber array collimator are 0.69°, 0.67°, 0.71°, and 0.68°, respectively, and the measurement expansion uncertainty is 0.02°, which is within the design tolerance limit of (0.68±0.03)°. The optical fiber collimator has good collimation characteristics and can meet the requirements of miniaturization and integration in the field of optical communication.