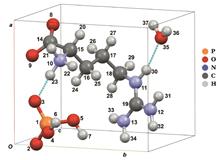

SignificanceL-arginine phosphate (LAP) crystals are high-performance nonlinear optical crystals that have garnered significant attention due to their high laser damage threshold and high frequency conversion efficiency, particularly in comparison to analogous crystals. Numerous unique properties have been identified through research. This paper reviews the exploration and advancements of LAP crystals over several decades, with a focus on the structure of LAP crystals, the growth of high-quality LAP single crystals, the mechanisms underlying the optical properties of LAP crystals, the surface morphology of LAP crystal, the application domains of LAP crystals, and the novel nonlinear optical crystals derived from LAP. LAP crystals hold considerable application potential in the field of nonlinear optics and are anticipated to be utilized in inertial confinement fusion (ICF). However, challenges remain in their practical applications.ProgressResearch has demonstrated that the compositional elements of phosphor arginine (PA) and LAP crystals are entirely identical. PA serves as a carrier for energy storage and transport in invertebrates, exhibiting a characteristic of molecular conformational variability during the storage and transportation of bioenergy. When energy is stored in PA, the interaction between the arginine molecule and the phosphate group induces a conformational transition from an extended structure to a bent structure; conversely, during transport, the conformation reverts. Similarly, LAP crystals also display a propensity for conformational variability under laser irradiation. The application of laser radiation results in a reduction in the number of Raman vibrational splitting peaks caused by phosphate groups within the LAP crystals, leading to an increase in the uniformity of the phosphate groups within the LAP crystals. This phenomenon suggests a trend towards a transition from distorted tetrahedral to regular tetrahedral configurations. The transfer of energy through conformational changes within the molecules enhances their resistance to laser damage, thereby providing a new explanation for the exceptional laser damage resistance of LAP crystals. This paper explores the relationship between the structural design and the mechanism underlying the ultra-high laser damage thresholds, theoretically investigating the electronic interaction among various functional groups. The findings offer a theoretical basis for material improvement and provide guiding insights for the future exploration of novel nonlinear optical materials. The high damage thresholds of LAP crystals are summarized in Table 1, indicating that, in all cases, the damage thresholds of LAP and deuterated LAP (DLAP) crystals exceed those of potassium dihydrogen phosphate (KDP) crystals and fused quartz, thereby highlighting the significant potential of LAP crystals for applications in high-power laser systems.L-arginine, an organic compound essential for various proteins, is required for the growth of LAP crystals. Prolonged crystal growth can lead to an increase in microbial populations within the solution, which may cause the mother liquor to become moldy. The incorporation of these impurities into the crystal lattice can adversely affect crystal quality. Therefore, preventing microbial contamination is crucial for the growth of high-quality, large-sized single crystals. The addition of substances such as liquid paraffin or n-hexane can effectively inhibit contamination and enhance crystal quality. The seed crystal method is employed to achieve large-sized LAP crystal growth, with stringent control over the saturation of the growth solution and meticulous regulation of the linear growth steps to improve crystal quality. Techniques such as solution overheating, continuous filtration, and thorough stirring are utilized to widen the metastable zone of the solution. This paper reports on the growth of large-sized LAP crystals measuring 170 mm×120 mm×60 mm by our research team.In the field of high-energy lasers, the characteristics of stimulated Brillouin scattering (SBS) indicate the potential of LAP crystals to enhance beam quality as phase conjugate mirrors. The DLAP crystal further reduces absorption at a wavelength of 1064 nm, demonstrating a higher SBS gain. The reflection of SBS diminishes transmitted energy, thereby protecting the crystal from damage. The capability of the DLAP crystal for aberration correction in a 10 Hz laser system is demonstrated, with the experimental setup illustrated in Fig. 5. The experiment utilizes a Nd∶YAG laser (wavelength λ=1064 nm, pulse width τ=12?13 ns), where the introduction of aberrations results in a divergence of 6 mrad. The assessment of the DLAP crystal ability to correct for aberrations is conducted through an examination of the far-field intensity profile. Additionally, in the terahertz (THz) domain, significant application potential has been exhibited. Arjun et al. reported for the first time that LAP crystals can generate THz radiation in the range of 0.1 THz to 2.0 THz. As the input power increases from 500 mW to 1200 mW, the THz output power is correspondingly enhanced. The measured refractive index and absorption coefficient of the crystal in the 0.1 THz to 2.0 THz range vary from 1.2 to 1.65 and from 5 cm?1 to 40 cm?1, respectively, indicating another promising application prospect for LAP crystals.Conclusions and ProspectsLAP crystals, as a novel nonlinear optical material originating from China, have garnered significant attention both domestically and internationally due to their exceptional comprehensive performance. Their potential application value in Inertial Confinement Fusion systems is particularly noteworthy, as they hold promise for further enhancing the frequency conversion efficiency and the laser damage thresholds of existing materials.

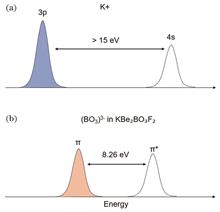

SignificanceMid-infrared (IR) nonlinear optical (NLO) crystals are crucial for a wide range of applications in both military and civilian sectors, including laser guidance, electro-optical countermeasures, medical diagnostics, and environmental monitoring. With the rapid advancements in solid-state laser technology and the increasing demand for high-repetition-rate, high-power mid-infrared laser output, there is an urgent need to develop new long-wave infrared nonlinear optical crystals with superior overall performance, particularly those with high laser damage thresholds. Pnictides are considered one of the most promising material systems for IR NLO crystals. However, due to the limited understanding of the optical bandgap mechanism in pnictides and the absence of effective bandgap tuning strategies to address their narrow bandgaps, the exploration of high-performance pnictide-based NLO crystals remains a significant challenge. This work summarizes and analyzes the literature data, explaining the microscopic structural mechanism by which alkali and alkaline earth metals, with their large ionic radii, fail to effectively widen the bandgap of pnictides. It also outlines design strategies and future directions for the development of wide bandgap pnictide-based NLO crystals. This work explains the bandgap mechanism of pnictides and proposes an optical bandgap tuning strategy for pnictide-based IR NLO crystals through a comprehensive analysis and synthesis of existing literature.ProgressCompared with those of sulfur and oxygen, the significantly weak electron affinity and electronegativity of pnictides are insufficient to stabilize non-bonding electron pairs formed by electron transfer from Alkali metals (IA)/ alkaline earth metals (IIA). As a result, these electron pairs become delocalized, leading to metal-metal interactions between the alkali/alkaline earth metals and adjacent P atoms, thus affecting the bandgap. These delocalized electrons occupy higher energy levels, with the conduction band maximum primarily determined by the non-bonding electron orbitals of P. Unlike oxides and chalcogenides, in pnictides-based compounds, the conduction band maximum is influenced not only by the P 3p orbitals but also by the (n-1)d empty orbitals of IA/IIA, which play a significant role in shaping the optical bandgap [Fig. 3(a)]. As the ionic radius of the IA/IIA decreases, its ionic polarization effect on adjacent P atoms intensifies (Table 3), and the interaction between them gradually transitions from a metal-metal interaction to a polar covalent interaction. The ionic nature of IA/IIA begins to positively influence the widening of the bandgap [Fig. 3(b)]. At this point, the valence band maximum and the conduction band minimum are primarily determined by the P 3p bonding orbitals in the covalent groups. Therefore, IA/IIA ions with small ionic radii and strong ionic polarization are effective in widening the bandgap of pnictides-based compounds. As the ionic radius increases, the ionic polarization ability of IA/IIA ions weakens, and the covalent interaction between IA/IIA and P disappears, leading to the formation of non-bonding P 3p electron pairs. Due to the weak electron affinity and electronegativity of P, these non-bonding electron pairs become delocalized, resulting in metal-metal interactions that reduce the bandgap (Fig. 5). Thus, regulating the bandgap in pnictides-based compounds should consider the delocalized distribution of valence electrons, due to the insufficient covalent coordination number of P atoms. This can be achieved through reasonable structural design and element coordination to control the ionic-covalent-metallic nature of the system. Based on this bandgap mechanism for pnictides, three approaches can be employed to design wide-bandgap pnictide-based NLO crystals: 1) Exploration of pnictides with P atoms having 3-coordinate (3CN) and 4-coordinate (4CN) structures; 2) Exploration of halopnictides containing halogens; 3) Exploration of pnictides with P—P homoatomic bonds.Conclusions and Prospects This article explains the microscopic structural mechanism by which alkaline metals and alkaline earth metals with large ionic radii cannot effectively widen the bandgap of pnictidesas the ionic radius of IA/IIA ions increases, their ability to polarize the ions of adjacent P atoms weakens. The covalent interaction between IA/IIA and P disappears, and non-bonding electron pairs of the P atom form. However, the contractive electron affinity and electronegativity of P atoms are incapable of stabilizing multiple non-bonded electron pairs, resulting in their delocalized distribution. Consequently, the metallic interaction occurs between alkali/alkaline-earth metals and neighboring P atoms, reducing the bandgap. The design strategies and the exploration direction for wide bandgap pnictide-based nonlinear optical crystals are proposed: 1) Pnictides with P atoms having 3CN/4CN, such as conventional diamond-like pnictides; 2) Halopnictides; 3) Pnictides with P—P homoatomic bonds.

SignificanceAs solid-state lasers develop toward higher power, better beam quality, miniaturization, and lower cost, they face such challenges as degraded optical performance caused by thermal effects (e.g., thermal lensing and thermal stress birefringence) induced by high-power pumping. Traditional gain media can no longer meet the demands for efficient energy conversion and specific wavelength output.Single-crystal fiber (SCF), a new type of laser gain medium typically with a diameter of tens to hundreds of micrometers, combines the advantages of crystalline materials (high thermal conductivity, high damage threshold, and excellent mechanical properties) and traditional optical fibers (high aspect ratio and large surface area). It significantly enhances the thermal management performance of laser gain elements, offering a promising solution to the aforementioned issues. SCFs can be prepared through mechanical processing, which is only suitable for SCFs with a diameter of approximately 1 mm—with sharply increasing processing costs and technical difficulties as the diameter decreases. They can also be directly grown from melts, with the main methods including micro-pulling-down (μ-PD) and laser-heated pedestal growth (LHPG). Among these, LHPG, featuring ultrahigh heating temperature (>3000 ℃), large temperature gradient (>4000 K/cm), and crucible-free growth, stands out as the optimal method for growing flexible SCFs with a core diameter of less than 100 μm.ProgressIn recent years, rare-earth-doped SCFs have achieved remarkable progress in laser oscillators and amplifiers. In the field of laser oscillators, in 2012, Délen et al. demonstrated the high-power output capability of 1%Yb∶YAG SCF. Using a 600 W, 940 nm laser diode (LD) for end pumping, they achieved a continuous laser output of 251 W with an optical?optical conversion efficiency of 44% (Fig. 8), setting a record for SCF laser output power. In 2020, the Liu team from Shandong University increased the 1064 nm continuous laser power of Nd∶YAG SCF to 72.3 W, with an efficiency of 47.3%. In 2025, Tang et al. from Harbin Institute of Technology used a 788 nm fiber-coupled LD to end-pump a composite-structured Tm∶YAP SCF, achieving maximum continuous laser outputs of 11.9 and 20.6 W under single-end and double-end pumping, with corresponding slope efficiencies of 53.2% and 40.7% (Fig. 11). In 2024, the Zhao team from Jiangsu Normal University used two serially connected 0.5%Ho∶YAG SCFs as the gain medium, pumped by a 1907 nm Tm-doped fiber laser (153 W pump power), achieving over 100 W output at 2.1 μm with an optical?optical conversion efficiency of 67.6% (Fig. 14). Constrained by the special energy level structure of Er ions, traditional Er-doped oxide crystals require high Er3+ doping concentrations to ensure laser efficiency, but strong absorption from high doping hinders the high aspect ratio advantage of SCFs, limiting their application in mid-infrared lasers. Our team grew Er∶CaF2 SCFs using the multi-microporous crucible method, realizing continuous laser operation of Er-doped SCFs at approximately 2.8 μm. The 3%Er∶CaF2 SCF achieved a maximum output of 0.939 W at 2756.9 nm, with a slope efficiency of nearly 35%, reaching the Stokes limit (Fig. 16). In laser amplifiers, Nd∶YAG and Yb∶YAG SCFs show potential in amplifying the power and energy of ultrashort pulses, with further pulse energy amplification achieved using such technologies as chirped pulse amplification (CPA), division pulse amplification (DPA), and coherent beam synthesis (CBC). In 2025, Cao et al. from Xi’an Institute of Optics and Mechanics realized high-peak-power ultrafast lasers based on a three-stage end-pumped Yb∶YAG SCF single-pass amplified CPA system, obtaining a near-transform-limited pulse width of 323 fs and a peak power of up to 2.6 GW (Fig. 25). In addition, progress has been made in SCF structural design. In 2018, Dubinskii et al. from the U.S. Army Laboratory grew an approximately 120-μm-thick pure YAG single-crystal film on a 100 μm 1%Yb∶YAG SCF using liquid phase epitaxy (LPE). This cladded SCF had a transmission loss of only 0.011 dB/cm at 632 nm, achieving a 68.7% optical?optical conversion efficiency and approximately 50 W quasi-continuous output at 1030 nm (Fig. 30). In 2023, our team achieved axial gradient doping of Nd∶YAG SCFs through source rod concentration distribution design based on LHPG, obtaining a maximum output of 6.46 W at approximately 1.06 μm with a slope efficiency of 44% (Fig. 31).Conclusions and ProspectsSCFs, with excellent thermal/mechanical properties, weak nonlinear effects, and a wide transmission band, hold great promise in high-power ultrafast and mid-infrared lasers. Progress in growing low-phonon-energy sesquioxide and fluoride SCFs facilitates mid-infrared laser power breakthroughs; with matured preparation processes and optimized laser designs/water cooling, mid-infrared outputs exceeding 100 W are expected. Future directions include improving cladding quality and core?cladding matching for long-distance waveguide gain amplification and integrating doping concentration design during growth to suppress thermal effects, thereby advancing laser power and efficiency.

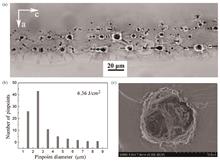

SignificanceWith the continuous advancement of inertial confinement fusion (ICF) research, the ultraviolet (UV) laser damage resistance of high-quality potassium dihydrogen phosphate (KDP)/deuterated potassium dihydrogen phosphate (DKDP) crystals has been steadily improving. However, the relationship between the laser damage performance of crystals and their growth parameters remains unclear. This is manifested in the lack of quantitative studies on the connections among various defects in crystals, growth parameters, and optical properties. Precursor defects inducing UV damage have not been experimentally observed or confirmed, resulting in numerous crystal damage phenomena that cannot be explained by physical models to date. In particular the nature of microscopic defects related to crystal damage under high fluence and the physical mechanisms by which they induce damage remain poorly understood. Consequently, research on improving crystal quality lacks fundamental microscopic understanding and technical approaches. The issue of UV laser damage caused by microscopic defects limits the application and service life of these crystals in high-power laser systems. Here we outline the laser damage mechanisms of KDP/DKDP crystals and summarize both experimental and theoretical researches on crystal damage-related defects, including recent progress in our own group.ProgressIn this paper, we first summarize the current domestic and international progress in damage researches on large-sized KDP/DKDP crystals and outline the primary physical mechanisms of laser damage. We then categorize the main types of defects present in KDP/DKDP crystals and their formation mechanism, summarizing the characterization methods for these defects reported in the literature as well as their impact on the optical properties of the crystal materials. Recently, we have analyzed the macro-distribution characteristics of hair inclusions using laser scattering techniques and have further conducted the statistical characterization of their micro-morphology. By combining the micro-Raman spectroscopy, we have identified the type of these hair inclusions. Based on their actual microscopic features, we have established a simulation model for defect-modulated light fields to study and analyze the field intensity modulation effects caused by inclusion defects within KDP crystals. Laser-induced damage testing was employed to investigate the influence of hair inclusions on the laser damage resistance of KDP-type crystals and analyze their damage mechanisms. Finally, we explored the origin of these hair inclusions. Regarding theoretical simulations, we employed first-principle calculations to study defect clusters composed of oxygen vacancies and surrounding intrinsic cation vacancies (hydrogen vacancies and potassium vacancies). We analyzed the impact of these defect clusters on KDP crystals from perspectives including their energetic stability, crystal structure, electronic structure, and linear absorption properties. Additionally, to theoretically study the damage generated on KDP crystal surfaces, we used first-principle methods to investigate the structural difference among KDP crystals and their dehydration products (K2H2P2O7 and KPO3). We calculated the electronic structures and optical properties of these three crystals. The results provided a scientific basis for a deeper understanding of the intrinsic mechanisms behind laser-induced damage growth on KDP crystal surfaces.Conclusions and ProspectsRegarding UV laser damage under high-fluence, studies on the damage characteristics of crystal components reported to date clearly indicate that the damage initiation precursors in crystals under high-fluence laser irradiation are nanoscale defect clusters inside the crystal material. The efficient, precise, and multi-scale characterization method for defects in crystal components is fundamental for investigating the origin of damage initiation and supporting the preparation of high-quality crystal materials, which is represented as a current bottleneck. Achieving characterization of such nanoscale defect clusters provides crucial evidence for establishing the correlation among crystal growth parameters and laser damage performance.

SignificanceAs a critical component of inertial confinement fusion (ICF), the research on the rapid-growth technology for large-sized deuterated potassium dihydrogen phosphate (DKDP) crystals has attracted significant attention worldwide. The control of growth and application costs for DKDP crystals as well as the regulation of the deuteration degree of the crystals and their performance are among the fundamental issues currently faced in improving load capacity.Neutron physics experimental methods are widely applied in materials science research with the following characteristics1) Neutrons interact with atomic nuclei through a non-monotonically varying scattering intensity function, making them suitable for determining light element positions in crystal lattices and distinguishing adjacent element positions; 2) Neutrons can differentiate between isotopes of the same element, enabling hydrogen-deuterium labeling which shows particular advantages in studying organic molecular materials and related fields; 3) Possessing magnetic moments, neutrons interact with atomic magnetic moments to generate unique magnetic diffraction, through which one can determine magnetic moment magnitudes and orientations of magnetic atoms in crystal lattices, serving as a crucial approach for studying magnetic structures; 4) Their significantly high penetration capability makes them particularly suitable for structural studies requiring specialized thick containers under extreme conditions like high/low temperatures and high pressure. The main limitations of neutron diffraction lie in requiring specialized intense neutron sources and the typical need for larger samples and longer data collection time due to insufficient source intensity. Currently, China possesses three major neutron science facilities: China Spallation Neutron Source (CSNS), China Mianyang Research Reactor (CMRR), and China Advanced Research Reactor (CARR).The current critical issues in enhancing load capacity and the hydrogen (H)-deuterium (D) network system of DKDP crystals are highly compatible with the research strengths of neutron physics methodologies. This paper, based on recent research results from both domestic and international sources, focuses on the application of neutron physics methods in the rapid growth technology of DKDP crystals and the study of laser damage. It also introduces our research progress in this field, points out research directions that should be continuously focused on, and looks forward to the application prospects of large-sized and high-quality DKDP crystals in the future.ProgressHigher performance standards have been imposed on critical optical components within laser transmission systems (Fig. 1). As ICF progresses toward higher energy levels in the future, the growth processes and defect control of DKDP crystals becomes research priorities, particularly exploring the relationship between process parameters and performance from microscopic perspectives, which forms the foundational scientific basis for advancing load capacity. The DKDP crystal structure is primarily dominated by ionic bonding, where each phosphorus (P) atom is coordinated by four oxygen (O) atoms arranged approximately at the vertices of a regular tetrahedron, forming PO4 groups, interconnected via H/D atoms (Fig.2). The unit cell parameters a and b increase with deuterium content, while parameter c shows no significant variation, resulting in relatively complete crystal structures for both low-deuterium and high-deuterium DKDP crystals (Fig. 3). Neutron diffraction methodology provides enhanced precision in quantifying H/D ratios and spatial localization within DKDP crystals. Experimental findings reveal that as the H—O and D—O bonds align parallel to the [100] and [010] crystallographic directions, deuterium content directly influences the lengths of O—O and P—O bonds in the structure (Table 1). The lighter mass of hydrogen facilitates quantum tunneling phenomena in O—H—…—O bonds, resulting in a more symmetric proton distribution between two oxygen atoms. This symmetry can lead to the formation of “quantum depolarization defects,” where PO4 groups fail to contribute to macroscopic polarization, thereby reducing the crystal spontaneous polarization strength and phase transition entropy. In contrast, D, with its heavier mass, exhibits a lower probability of quantum tunneling. D tends to deviate from the hydrogen bond center, forming an asymmetric distribution, which enhances the crystal spontaneous polarization strength and phase transition entropy. These microscopic characteristics manifest distinct differences in the optical field response of high-power laser systems, which is identified by the simulation (Fig. 4).Current challenges in crystal growth primarily include the following aspects1) Cone-column interface. Crystals grown via rapid growth methods exhibit distinct cone-column interfacial boundaries, which can induce phase jumps under optical field conditions, compromising homogeneity, and limiting their application in ICF engineering. Implementing controlled growth environments with structured constraints can improve crystal quality and growth efficiency (Fig. 5). 2) Nonuniform D distribution. Studies have investigated flow field states on crystal surfaces under varying growth conditions through hydrodynamic simulations, proposing optimized flow field strategies. Neutron imaging enables precise detection of H and D distributions in DKDP crystals, facilitating exploration of D-content variations in growth solutions and their impact on the growth process. Coupled with finite element simulations, this approach identifies correlations between growth parameters and flow field dynamics, thereby optimizing growth protocols to mitigate lattice mismatch, local overcooling, and deuterium inhomogeneity, ultimately enhancing crystal quality and laser damage resistance. 3) Residual stress in crystals. Three types of residual stresses arise during crystal growth. Neutron diffraction techniques allow noninvasive measurement of residual stress in DKDP crystals, revealing internal stress levels. Research indicates that macroscopic stress does not increase with deuterium content. Maximum lattice mismatch and microscopic strain occur when the mass fractions of H and D in the crystal are both 50%, with defects identified as the source of macroscopic residual stress. Additionally, developing real-time monitoring systems to track stress field dynamics and relaxation processes can provide critical feedback for refining key growth parameters.Conclusions and ProspectsFor significantly enhancing device load capacity, it is crucial of optimizing the entire operational workflow of DKDP components. As the initial stage of the workflow, crystal growth process optimization and fundamental research on ultraviolet damage response can systematically address engineering challenges. This paper focuses on the application of neutron physics methods in DKDP crystal growth and laser damage studies, where notable progress has been made. However, future work still faces multiple challenges. With the rapid development of large scientific facilities like CSNS, future neutron diffraction technology will advance towards higher resolution, faster dynamic response, and multi-physical field coupling analysis. Combined with X-ray and synchrotron radiation methods, these techniques can provide atomic-scale scientific insights for the regulation of DKDP crystal growth. Supported by theoretical simulations, closed-loop optimization of processes, structures, and properties is expected to achieve controllable preparation of large-size, low-stress DKDP crystals. Through collaborative efforts from Chinese researchers, DKDP crystals are anticipated to continue playing critical roles in laser fusion, high-energy laser systems, and emerging optoelectronic applications.

SignificancePotassium tantalate niobate (KTa1-xNbxO3, KTN) crystals exhibit the largest quadratic electro-optic (EO, Kerr) coefficient among known materials. This extraordinary property enables electro-optic modulators to operate at driving voltages below 100 V, fundamentally overcoming the “kV bottleneck” that has historically constrained device miniaturization and energy efficiency in photonic systems. The technological implications are profound: such ultra-low-voltage operation is critical for portable biomedical imaging probes [e.g., endoscopic optical coherence tomography (OCT)], integrated optical communication chips, and compact three-dimensional (3D) sensing receivers where power consumption and footprint dictate feasibility. Beyond the Kerr effect, KTN’s tunable phase transitions and broadband optical transparency (250?5000 nm) offer unprecedented versatility in designing wavelength-agile devices for applications from near-infrared (NIR) telecommunications to mid-infrared (mid-IR) sensing. However, decades of research has revealed persistent barriers to practical adoption. The crystal’s infinite solid-solution behavior between KTaO3 and KNbO3 eliminates a congruent melting point, while sequential cubic→tetragonal→orthorhombic phase transitions during cooling induce severe compositional striations, cracking, and defects. Concurrently, challenges in understanding novel physical effects (e.g., space-charge-controlled deflection and ferroelectric domain engineering) have hindered practical applications. This review addresses these gaps by systematizing breakthroughs in crystal growth, property characterization, and device design, and synthesizes transformative advances in overcoming these challenges, establishing a unified framework to harness KTN’s full potential for next-generation photonics.ProgressKTN’s infinite KTaO3-KNbO3 solid-solution system and multi-phase transitions demand innovative growth strategies. For Czochralski method (Fig. 3), undercooling isothermal growth technique stabilizes the growth interface by minimizing temperature fluctuations, and double-crucible real-time feeding system continuously supplies stoichiometric material, suppressing compositional segregation. Combined with both technology, device-grade crystal up to 35 mm×37 mm×58 mm with Ta/Nb compositional uniformity better than 10-5/mm (Fig. 4) is achieved. For hydrothermal method, temperature-difference hydrothermal growth [Fig. 5(b)] enhances homogeneity by minimizing component segregation. Adding H2O2 eliminates blue color centers [Fig. 6(c)], though crystal size remains sub-centimeter.Systematic studies reveal composition-property relationships. Lattice parameter a increases linearly with Nb content x (Table 1). At x=0.37?0.39, KTN achieves optimal dielectric constant (εr>50000) near room temperature. The Kerr coefficient can be directly enchanced via the Curie-Weiss law. Cu2+/Fe3+ doping (0.5%?1% atomic fraction) enhances dielectric response [Fig. 15(d)] and optical homogeneity via trace-impurity-induced dielectric enhancement (e.g., Fe3+-oxygen vacancy dipoles polarize microregions, shifting TC by 60 ℃). Transverse deflection is observed in Cu∶KTN. A compositional gradient generates intrinsic refractivity variations. Coupling this with the Kerr effect under an external electric field produces laser deflection perpendicular to the field direction [Fig. 19(a)], contrasting conventional longitudinal models. Self-powered photoresponse in engineering “head-to-head” charged domain walls (CDWs) creates built-in fields for carrier transport. Cu∶KTN detectors achieve 5.23 mA/W responsivity (four orders higher than that of BaTiO3) (Fig. 12) and 250?1030 nm spectral coverage [Fig. 13(d)].Devices based on KTN crystal were well developed. Space-charge-controlled KTN beam deflectors achieve 250 mrad deflection at ±250 V [Fig. 18(b)], 80 times more efficient than LiNbO3 deflectors.A maximum modulation contrast model of KTN electro-optic modulators optimizes bias voltage, tripling contrast (0.106 versus 0.03). Room-temperature operation at 395 V half-wave voltage (Fig. 26) is enabled by giant Kerr coefficients (S11=2.2×10-14 m2/V2), orders of magnitude higher than those of conventional electro-optic crystals. Periodically poled KTN (PPKTN) exhibits 39% second-harmonic generation (SHG) efficiency at 1030→515 nm [Fig. 22(e)] and covers mid-IR (5→2.5 μm) band via quasi-phase matching, filling a critical gap in mid-IR laser sources.KTN-based devices are poised to enable wide-bandwidth, high-efficiency laser systems for lidar, OCT (Fig. 23), and ultrafast 3D imaging (Fig. 24). KTN-deflector-based swept-source systems scan at 100 kHz rates, resolving strawberry tissue structures at 7 μm axial resolution (100 nm wavelength sweep). Utilizing KTN’s optical isotropy and ultrahigh Kerr coefficient, polarization-modulated 3D lidar achieves 20° field-of-view with 4.4 cm precision at 15 m distance, 60% lower error than DKDP-based systems. KTN large-angle scanners enable synthetic aperture imaging with times wider scan angles than traditional EO crystals [Fig. 24(d)].Conclusions and ProspectsKTN crystals have demonstrated transformative potential in high-efficiency deflectors, low-voltage electro-optics, nonlinear photonics, and self-powered photodetection. Critical future directions include the following aspects. 1) Growth challenges: scaling hydrothermal crystals to device sizes and improving temperature stability during growth. 2) Device optimization: developing precise thermal control systems for Kerr-effect-based modulators operating near TC. 3) High-frequency mechanisms: exploring gigahertz modulation dynamics and field-induced phase transitions. 4) Emerging applications: leveraging scale-free optics and ferroelectric superlattices for quantum optics and integrated photonics. By resolving the dual frontiers of crystal homogeneity and physical understanding, KTN-based technologies are poised to redefine performance ceilings in high-speed optical modulation, energy-autonomous photodetection, and nonlinear frequency conversion.

SignificanceAs a representative of third-generation semiconductor materials, silicon carbide (SiC) has emerged as a revolutionary substrate for high-power electronic devices, radio frequency (RF) components, extreme-environment sensors and future quantum technologies due to its outstanding properties, including a wide band gap, high thermal conductivity, high breakdown electric field, high electron saturation drift velocity, excellent chemical stability and high-temperature tolerance. The exceptional thermal conductivity of SiC is particularly critical for mitigating self-heating effects in wide-bandgap semiconductor devices such as GaN and Ga2O3. However, the performance enhancement and broad application of SiC-based devices face a fundamental bottleneck: conventional heteroepitaxial growth technologies, such as GaN/SiC, InP/SiC, and 3C-SiC/Si, inevitably introduce defects like high-density interface dislocations and cracks. These stem from significant lattice mismatch and differences in thermal expansion coefficients between materials, leading to substantial degradation in device performance. Moreover, high-quality crystal forms such as 4H-SiC cannot be directly epitaxially grown on mainstream substrates like silicon, which severely restricts material choices and limits the design freedom for heterogeneous integration.In this context, wafer bonding offers breakthrough solutions and demonstrates significant research value. Direct bonding techniques, such as surface-activated bonding and plasma-activated bonding, enable precise nanoscale control of the interface. These methods effectively circumvent issues related to lattice mismatch and thermal stress, confine defects to an ultrathin interfacial region, and largely preserve the intrinsic properties of functional materials. The core significance of this approach lies in three aspects. 1) Enabling homogeneous SiC bonding to construct three-dimensional power modules with low interface resistance and high thermal stability, thereby reducing the cost of large-size wafer production. 2) Unlocking the potential for heterogeneous integration of SiC. As a high-thermal-conductivity substrate, SiC can be bonded with materials such as Ga2O3, diamond, Si, GaAs, and InP, substantially improving heat dissipation efficiency. Leveraging mature silicon processes also promotes the development of high-density integrated circuits, while intermediate layer technologies further optimize interfacial performance. 3) Providing large-size, low-cost integration solutions. Therefore, in-depth research on SiC wafer bonding technology is not only critical to addressing the key bottlenecks of currently limiting SiC-based device performance and unleasing its vast application potential, but also serves as a core driver advancing semiconductor heterogeneous integration technology toward higher performance, broader material compatibility and lower cost. It holds profound strategic significance for the innovation and application of next-generation semiconductor devices.ProgressAs a key process in semiconductor manufacturing, the advancement of wafer bonding technology plays a vital role in enhancing device performance. This paper provides a systematic review of the research progress and application of SiC wafer bonding technology. First, the classification system of wafer bonding technologies is summarized, with a focus on two representative methods prominent in the SiC field. One is surface activation technology tailored for SiC material characteristics, including plasma activation bonding and room-temperature surface activation bonding. These techniques significantly reduce the required temperature and pressure for bonding through pretreatment. The other is Smart Cut technology, which combines ion implantation and bonding processes. This approach is particularly suitable for producing high-quality thin-film composite substrates, such as silicon-on-silicon carbide on insulator (SiCOI) structures, offering an ideal material platform for subsequent device fabrication. Second, this review details specific technical pathways for SiC wafer bonding. This includes heterogeneous bonding between SiC and other semiconductor materials, such as Si, Ga2O3, and InP, which aims to integrate the superior properties of different materials to expand device functionality. Also covered is homogeneous bonding between SiC wafers, which is essential for producing large-size, high-quality SiC substrates or specific structural devices such as micro electro mechanical system (MEMS) sensors. The paper examines various bonding methods along with key process parameters and associated challenges. Third, this paper highlights application examples of SiC-based devices that demonstrate the practical value of bonding technology. These include: MEMS sensors based on SiC homogeneous bonding, which exhibit high-temperature and radiation-resistant properties; photonic devices enabled by SiCOI structures, benefiting from its superior optical confinement; RF devices fabricated by bonding piezoelectric materials such as lithium niobate (LiNbO3) with SiC, combining efficient energy transduction with the high-frequency and high-power advantages of SiC; high-performance, low-cost SiC power devices produced by bonding high-quality single-crystal SiC layer with low-cost polycrystalline SiC or reclaimed single crystal SiC substrates via the Smart Cut process. Finally, the paper systematically summarizes the critical influence of these wafer bonding methods on the final bonding quality and the thermal performance of devices, offering valuable reference for researchers and engineers in selecting and optimizing bonding processes.Conclusions and ProspectsSiC wafer bonding technology effectively overcomes the thermal conduction bottlenecks and self-heating effects inherent in traditional semiconductor materials through heterogeneous integration. It enables low-damage bonding of SiC with Si, Ga2O3, InP and various insulating substrates, while also driving advances in homogeneous bonding toward larger wafer sizes and lower stress levels. This progress provides high-performance solutions for power devices, RF modules, MEMS sensors and photonic integration platforms. The core focus of future research lies in further uncovering the physico-chemical mechanisms at the bonding interface. There is a need to systematically elucidate the relationships among interfacial thermal resistance, contact resistance and bonding strength. Concurrent development of advanced processes, such as those enabling low lattice damage, submicron alignment, and reduced wafer warpage, is essential, with particular emphasis on defect control and energy band engineering in oxide intermediate layers. By establishing quantitative models that link the microstructural characteristics of the interface to its macroscopic electro-thermal-mechanical properties, collaborative optimization across multiple physical fields can be achieved. This will ultimately unlock the full potential of SiC wafer bonding in applications such as extreme-environment electronics, high-efficiency energy conversion, and high-speed optical communications, paving the way for a new generation of heterogeneous integrated material platforms that surpass the limitations of silicon-based technologies.

SignificanceLaser-driven inertial confinement fusion (ICF) stands as a pivotal approach in the quest for clean and virtually limitless energy, a concept first proposed in the 1960s. The fundamental principle involves using high-power lasers to symmetrically irradiate a fuel-filled target, compressing and heating the fuel to conditions where nuclear fusion can occur. A critical parameter in this process is the laser wavelength. It has been established that using short-wavelength ultraviolet (UV) lasers, typically generated through frequency conversion of infrared (IR) lasers, offers indispensable advantages. These include more efficient energy absorption by the target, better control over plasma instabilities, and reduced generation of undesirable high-energy electrons, all of which are crucial for achieving fusion ignition.The significance of this technology was brought to the forefront by the historic achievement at the U.S. National Ignition Facility (NIF) in December 2022, where a net energy gain from a fusion reaction was demonstrated for the first time. This milestone, which relied on converting 2.05 MJ of infrared laser energy into 3.15 MJ of fusion energy using third-harmonic generation (THG) in potassium dihydrogen phosphate (KDP) crystals, has profoundly boosted global confidence in the potential of laser fusion energy. As the field now looks beyond single-shot ignition experiments towards the development of a commercially viable fusion power plant, the requirements for laser drivers are evolving. Future laser fusion energy drivers must not only deliver high energy but also operate at high repetition rates (>10 Hz). This shift introduces a formidable challenge: managing the substantial heat deposited in the frequency conversion crystals due to laser absorption. Consequently, the development of nonlinear optical crystals with superior thermal and optical properties, coupled with advanced thermal management technologies, has become a critical bottleneck and a key research focus for realizing the dream of laser fusion energy.ProgressThis paper provides a comprehensive review of the progress in frequency conversion technology for laser fusion drivers, from the foundational developments in single-shot systems to the cutting-edge research for future high-repetition-rate energy drivers.The development of high-efficiency THG for large-scale ICF facilities has been a gradual process of engineering maturation. The nonlinear optical crystals used, primarily KDP and its deuterated form (DKDP), must meet stringent criteria, including high damage threshold, good optical homogeneity, and the ability to be grown to large size (approaching 400 mm). Early large-scale implementation on the Nova laser in the 1980s pioneered the use of a 3×3 segmented crystal array to overcome limitations in single-crystal growth size (Fig. 1). Employing a “Type-II/Type-II” phase-matching scheme, Nova achieved a THG conversion efficiency of over 60% (Fig. 2), providing the first major scientific validation of large-energy UV laser drivers. However, the segmented design introduced diffraction effects that degraded beam quality. The subsequent Beamlet laser, a prototype for NIF, introduced two key innovations: monolithic (single-piece) large-aperture KDP/DKDP crystals and a more robust “Type-I/Type-II” phase-matching scheme [Fig. 3(a)]. This new approach was less sensitive to polarization and temperature variations, consistently achieving over 70% efficiency and demonstrating superior stability [Fig. 3(b)]. The NIF facility inherited and scaled up this architecture, further refining crystal growth to achieve more than 80% THG efficiency with 42 cm crystals, setting the global standard for modern ICF drivers (Table 1).China’s Shenguang series of laser facilities have also made significant strides. Initially, these facilities faced a bottleneck where the THG efficiency would plateau and fall away from theoretical predictions at high input intensities (Fig. 4). To address this, researchers at the China Academy of Engineering Physics (CAEP) conducted a systematic analysis, identifying and precisely controlling several critical factors that contribute to phase mismatch. Key breakthroughs included improving the optic axis and deuterium content uniformity in DKDP crystals, optimizing crystal mounting techniques to minimize wavefront distortion, and developing an advanced temperature control system capable of maintaining uniformity to within 0.05 ℃, surpassing the NIF specification (Fig. 5, Table 2). The successful integration of these advancements led to a landmark achievement: a stable THG efficiency of over 80% was demonstrated on a 430 mm aperture system, with a peak efficiency of 82.8%, which was in excellent agreement with theoretical models (Fig. 6).Research has also extended to higher-order harmonics, as even shorter wavelengths could further enhance laser-plasma coupling. Significant progress has been made in fourth-harmonic generation (FHG). Researchers at CAEP developed an innovative scheme using non-critical phase matching (NCPM) in a 65% deuterated DKDP crystal within a converging beam. This technique achieved a remarkable 82% conversion efficiency from second-harmonic to fourth-harmonic light, generating over 180 J of UV output (Fig. 7). Fifth-harmonic generation remains challenging due to material limitations and higher susceptibility to optical damage and thermal effects, with current efficiencies around 14%?30%.For future fusion energy drivers, the primary challenge shifts to managing thermal effects in high repetition rate and high average power operation. Comparative studies of different crystals for second-harmonic generation (SHG) at 10 J/10 Hz revealed that while DKDP suffered from thermal dephasing, YCOB’s performance was limited by material quality, and lithium triborate (LBO) showed excellent performance, achieving 82% efficiency at 0.7 GW/cm2 (Table 3, Fig. 8). Building on this, the Bivoj/DiPOLE laser facility set a new world record, producing 50 J of third-harmonic energy at a 10 Hz repetition rate using large-aperture LBO crystals (Fig. 9). However, thermal gradients were still observed to evolve in the crystal over time, affecting the beam profile (Fig. 10). In China, research on a 100 Hz system demonstrated 3 J SHG output using an LBO crystal with a micro-channel cooling system that precisely controlled temperature to within ±0.05 °C (Fig. 11), demonstrating a scalable path towards kilowatt-level average power.Conclusions and ProspectsFrequency conversion technology is a cornerstone of mainstream laser fusion research. For single-shot, large-scale facilities like NIF, the technology based on KDP/DKDP crystals is mature, and China has recently demonstrated a breakthrough in achieving over 82% third-harmonic conversion efficiency through meticulous engineering controls. However, for the next generation of fusion energy drivers operating at high repetition rates, significant challenges remain. The thermal effects, optical damage, and long-term stability of nonlinear crystals under high average power are unresolved physical problems that require comprehensive breakthroughs.Future development should focus on three synergistic directions. First is the development of advanced crystal materials with lower absorption, higher damage thresholds, and larger nonlinear coefficients. This includes exploring alternatives like large-scale LBO and innovative concepts like composite “sandwich” crystal structures or artificially micro-structured materials. Second is the advancement of thermal management engineering. Techniques such as bonding crystals to high-conductivity heat sinks or using a gas-cooled, sliced-crystal-stack architecture must be perfected to handle kilowatt-level average powers. Third, the application of intelligent control systems is crucial. By integrating multi-physics modeling with AI-driven, real-time feedback from distributed sensors, future systems can dynamically predict and compensate for thermal distortions, ensuring stable, efficient, and reliable operation. The successful integration of these advancements will pave the way for a robust frequency conversion solution capable of meeting the demanding requirements of a laser fusion power plant.

SignificanceLithium niobate (LiNbO3) has played an essential role in the fields of electro-optic modulation and frequency conversion. In its early stages, it was primarily used as laser frequency-doubling devices and electro-optic modulators in optical communication systems. With the advancement of Ti-diffusion and proton exchange techniques, LiNbO3 devices were no longer confined to bulk configurations, facilitating the development of a range of integrated optical waveguide components. However, challenges in nanofabrication and constraints on integration density still persist. In the 21st century, with the explosive growth of information and data, traditional electronic computing is gradually approaching its physical limits. Emerging applications, including big data, artificial intelligence, high-speed networks, and virtual reality, are placing increasingly demanding requirements on computing devices in terms of performance, size, and energy efficiency.Owing to its exceptional electro-optic and nonlinear optical characteristics, LiNbO3 remains pivotal in traditional communication technologies, while also demonstrating irreplaceable value in emerging fields such as optical computing, artificial intelligence acceleration, and quantum information processing. In particular, the rise of the thin-film lithium niobate (TFLN) platform marks a new era for LiNbO3 as a platform for optical computing chips, which may have a tremendous impact on the future of information technology.TFLN, when combined with advanced nanofabrication techniques, has facilitated the development of compact, low-loss, high-speed photonic devices. TFLN has become a critical material platform for the development of high-speed electro-optic modulators, nonlinear photonic chips, and quantum photonic circuits. TFLN has gained increasing attention in the field of optical computing primarily due to the following reasons: Firstly, its strong electro-optic effect fulfills the high-speed modulation requirements for optical computing. Moreover, the low optical loss and high bandwidth of TFLN enable optical signal transmission over a broad frequency range with minimal attenuation. Finally, TFLN supports ultra-high integration density, making it suitable for constructing compact and miniaturized photonic integrated circuits (PICs).In recent years, the demand for computing processing speed has been approaching the performance bottleneck of electronic computers. Optical computing, as a computing system that relies on photons to process data, has advantages such as low energy consumption, large bandwidth, and fast response, making it one of the most promising disruptive computing architectures. Optical computing is of strategic importance to safeguarding information security and computational sovereignty. Lithium niobate materials and photonics have long been a significant research focus in China, and a series of significant breakthroughs have already been achieved in recent years. Therefore, a systematic review of the progress and prospects of LiNbO3-based optical computing is essential to guide future research and technological development.ProgressFigure 1 shows the microscopy image of the fabricated chip, which consists of three Mach?Zehnder modulators (MZMs) with various microwave signal line widths and device lengths. Figure 2 presents the schematic of the cross-section of the hybrid waveguide, as well as the multifunctional photonic integrated chip and its characterization system. An integrated lithium niobate (LN) modulator with segmented electrodes (designed to reduce the modulation voltage) has significantly enhanced the modulation bandwidth (Fig. 3). Figure 4 depicts the schematic of an MZM with a periodic CLTW (capacitively loaded traveling-wave) electrode. Figure 5 illustrates the architecture of a typical hybrid photonic neural network (PNN). Figure 6 shows a schematic of the proposed integrated photonic tensor core (IPTC), which consists of four physical components: lasers, two TFLN MZMs, and charge-integration photoreceivers. Figure 7 presents the conceptual schematic of a fully integrated optical convolutional neural network (OCNN), which uses an integrated photonic convolution accelerator (IPCA) fabricated on the lithium niobate-on-insulator (LNOI) platform and a micro-ring resonator (MRR) filter. Figure 8 shows an LN-based microwave photonics (MWP) processing engine, which consists of a high-speed electro-optic modulation block and a low-loss, multipurpose photonic processing section. The implementation of the photon ray-tracing core (PRTC) on the TFLN platform is shown in Fig. 9; the PRTC comprises four high-speed push-pull MZMs for parameter encoding, followed by coherent optical processing and detection components for binary result generation. A polarized TFLN waveguide was fabricated, and non-destructive high-resolution in-situ imaging technology was used for characterization (Fig. 10). Figure 11 provides the experimental setup for characterizing the photon pairs generated from the LNOI waveguide. Furthermore, a photonic chip with dimensions of 50 mm×5 mm×0.5 mm (capable of generating and manipulating entangled photon pairs) has been reported (Fig. 12). Finally, the experimental setup for measuring on-chip quantum interference is also showcased (Fig. 13); this setup can realize multiple photonic information processing functions, including on-chip quantum interference and photon demultiplexing.Conclusions and ProspectsThe emergence of TFLN has driven revolutionary advances in multiple fields, including optical modulation, nonlinear optical devices, optical computing, and quantum optics, thereby propelling the development of LiNbO3-based optical computing chips. Notably, critical performance metrics such as operational bandwidth, processing speed, and energy efficiency have undergone remarkable improvements. Importantly, some LiNbO3 optical computing chips fabricated in laboratories have already achieved performance levels suitable for market applications. However, the industrialization of LiNbO3 optical computing is still constrained by challenges in material fabrication, nanofabrication techniques, integration density, and system complexity. Bridging the gap from laboratory prototypes to commercial products will require coordinated efforts across materials science, optical engineering, and computing architecture.

SignificanceIn recent years, lithium niobate (LiNbO3, LN) and lithium tantalate (LiTaO3, LT) thin films have attracted intense research interest due to their excellent electro-optic, piezoelectric, and nonlinear optical properties. By integrating these ferroelectric oxide films with silicon and other substrates, chip-scale photonic and acoustic devices have achieved remarkable performance improvements. This work reviews the state-of-the-art in heterogeneously integrated devices based on LiNbO3/LiTaO3 thin films, highlighting the importance of these platforms for next-generation communication, sensing, and quantum applications.ProgressConsiderable progress has been made in fabricating high-quality LiNbO3/LiTaO3 thin films using techniques like chemical vapor deposition (CVD), molecular beam epitaxy (MBE), pulsed laser deposition (PLD), magnetron sputtering, and smart cut, with each method presenting unique advantages and challenges in composition control, crystallinity, and scalability (Fig. 1, Table 1). For instance, CVD and sputtering enable large-scale production, while MBE and PLD offer atomic-level control for precision devices, and smart cut has become the industry standard for LiNbO3 on insulator (LNOI) substrates in commercial modulators and filters (Fig. 1). Domain engineering via femtosecond laser writing and piezoresponse force microscopy (PFM) allows nanoscale manipulation of ferroelectric domains, enhancing nonlinear and electro-optic properties (Figs. 2 and 3). In on-chip lasers, rare-earth-doped (e.g., Er-Yb co-doped) microring/microdisk lasers achieve ultra-low thresholds (~1 μW), while LN microresonator-based stimulated Raman lasers cover 1592‒1955 nm with sub-mW thresholds (Fig. 4). Optical parametric oscillators (OPOs) on LN films enable wide tuning (1.5‒3.3 μm), and Pockels-effect tunable lasers show record-high frequency sweep rates (2×1018 Hz/s) and ultra-narrow linewidths (<200 Hz), promising for coherent lidar (Fig. 5). Electro-optic modulators on LN/LT thin films feature reduced half-wave voltage (Vπ·L < 1 V·cm), ultra-high bandwidth (>100 GHz), and low insertion loss (<7.47 dB) via artificial microstructured electrodes and high-κ dielectric claddings (Fig. 6). LT modulators exhibit superior DC stability (e.g., <1 dB power fluctuation over 46 h) and lower photorefractive effects, outperforming LN in cost-effective scalability for high-speed communications (Fig. 7). In quantum photonics, LN/LT films enable efficient quantum frequency conversion (73% internal efficiency), single-ion Purcell enhancement (Purcell factor >170) in Er3+-doped photonic crystal cavities, and all-optical readout of superconducting qubits, eliminating cryogenic microwave components (Figs. 8 and 9). For acoustics, LN/LT thin-film-based surface acoustic wave/bulk acoustic wave (SAW/BAW) filters on platforms like LNOI, LN/SiO2/Si, and LN/SiC achieve 18.2% fractional bandwidth at 23.5 GHz with 2.38 dB insertion loss, and sub-1.2 dB loss at lower frequencies, addressing 5G/6G demands via optimized film orientation and electrode designs to suppress spurious modes (Figs. 10 and 11).Conclusions and ProspectsLithium niobate and lithium tantalate thin films have established a versatile platform for high-performance heterogeneous integration. Future research will focus on scaling to larger wafers, improving yield, and extending operation into new frequency ranges (e.g., millimeter-wave photonics). Advances in hybrid integration (e.g., LiNbO3 on insulator, LiTaO3 on insulator) and novel device architectures will further enhance functionality. Overall, the unique material properties of lithium niobate and lithium tantalate thin films—including high electro-optic coefficients, strong nonlinearity, and excellent thermal stability—position them to drive breakthroughs in high-speed, low-power photonic and acoustic devices. These advancements will pave the way for ultra-compact solutions in optical communications, lidar systems, and quantum photonic technologies, enabling next-generation applications in information processing and sensing.

SignificanceQuantum information technology (QIT), a key frontier field emphasized in China’s “14th Five-Year Plan” and the 2035 long-term development goals, serves as a core driver for leading the new round of scientific and technological revolution and industrial transformation. Its in-depth development is of great significance for enhancing national technological competitiveness, promoting innovation-driven development, and breaking through bottlenecks in traditional information technologies. As a critical material foundation for quantum devices, diamond stands out among numerous quantum materials due to its exceptional optical, mechanical, and electronic properties. It is one of the few materials capable of achieving stable manipulation of quantum states at room temperature, thus playing an irreplaceable role in the construction of high-performance quantum information processing systems. Notably, the nitrogen-vacancy (NV) color center in diamond—a point defect formed by a nitrogen atom and an adjacent lattice vacancy—exhibits extraordinary magnetic sensitivity at room temperature. This unique characteristic stems from its ability to realize precise manipulation of quantum states through laser polarization and microwave regulation, enabling high-precision measurement of weak magnetic fields even in complex environments. This endows it with broad application prospects in biomedicine, geological exploration, and industrial detection.In power systems, traditional magnetometers based on the principle of electromagnetic induction have long faced inherent limitations. For instance, they struggle to balance high precision and a wide measurement range, suffer from significant temperature drift during long-term operation, and are difficult to miniaturize for integration into smart grid sensor networks. These drawbacks severely hinder the advancement of intelligent monitoring of power grids, especially in scenarios such as high-precision DC current measurement and real-time status monitoring of power equipment. Against this backdrop, research on quantum magnetometers based on diamond NV color centers holds substantial scientific value and practical significance. It not only offers a novel technical pathway to overcome the bottlenecks of existing measurement technologies but also promotes the development of intelligent, integrated, and low-power-consumption measurement equipment. Furthermore, in-depth exploration of NV color center technology advances the practical application of quantum sensing, bridges the gap between fundamental quantum research and engineering applications, and lays a solid foundation for the innovative development of QIT in engineering fields such as energy, aerospace, and intelligent manufacturing.ProgressThis study first introduces the basic structure of NV centers and the principles of magnetic measurement (Fig. 1), with a particular focus on the continuous wave optical detection of magnetic resonance (CW-ODMR) method. It then details the fabrication processes of NV center diamonds, including high-pressure high-temperature (HPHT) synthesis (Fig. 4) and chemical vapor deposition (CVD) methods (Fig. 5), as well as subsequent processing steps. The advantages of ensemble diamond parameters are also discussed. Subsequently, the framework of the quantum magnetometer system is elaborated (Fig. 7), and the integration and development of quantum magnetometers are reviewed (Fig. 10). The current fabrication methods of diamond quantum magnetometers are summarized, highlighting the overall trends toward system integration, probe miniaturization, high sensitivity, and low power consumption. In the latter part of the paper, the current status of current sensors is detailed (Table 4). Traditional current transformers face certain limitations in achieving high-precision measurement, a wide dynamic range, and miniaturization of measurement probes, which significantly constrain the progress of smart grid research. To address these challenges, the application of quantum current transformers (QCTs) based on NV centers (Fig. 11) is introduced, and their use in power grid current transformers is explored, offering a novel solution for current monitoring. This study also compares different QCTs (Table 5) and further demonstrates the multifaceted application potential of diamond NV center quantum devices. Finally, the existing challenges of NV center magnetometers are discussed, and future research directions are proposed.Conclusions and ProspectsResearch on diamond NV center-based quantum magnetometers has made steady progress. The room-temperature quantum manipulation capability, high magnetic sensitivity, and relative stability in complex environments of these magnetometers have alleviated some of the limitations of traditional magnetometers and laid the foundation for high-precision magnetic field measurements—especially in power system monitoring. However, current challenges remain, including the high cost of high-quality diamond fabrication, difficulties in system miniaturization, and the need to improve measurement accuracy and noise suppression. Future efforts should focus on optimizing diamond growth and post-processing techniques to reduce costs and enhance the performance of NV ensembles, advancing system integration to improve portability and noise suppression capabilities, and exploring multi-physical-parameter sensing to expand application scenarios. These measures will facilitate the practical application of NV center technology in the field of quantum sensing.

SignificanceLarge-aperture potassium dihydrogen phosphate (KDP) and deuterated potassium dihydrogen phosphate (DKDP) crystals are the only nonlinear optical materials suitable for serving as frequency conversion elements and optical switches in high-power laser facility. However, their anisotropy, soft-brittleness, hygroscopicity, thermal sensitivity, and propensity for cracking impose significant challenges to ultra-precision manufacturing. Conventional grinding and polishing processes are prone to leaving abrasive particles embedded on the surface. These particles serve as precursors to laser-induced damage, significantly diminishing the laser damage resistance of the crystals. Consequently, the simultaneous attainment of full spatial-frequency bandwidth precision and a high laser-induced damage threshold (LIDT) constitutes a pivotal challenge in the advancement of high-power laser facility.ProgressTo address these challenges, an integrated technical route of “single-point diamond turning (SPDT) + sub-nanosecond laser conditioning + sol-gel coating” has been established. Significant progress has been made in the following areas.Ultra-precision cutting technology and equipment: an anisotropic constitutive model for soft-brittle crystals was developed to reveal the brittle-ductile transition (BDT) behavior during cutting (Fig. 1). Simulations identified the optimal cutting direction along 45° within the (001) plane and a BDT depth of approximately 150 nm. Through process optimization and the innovative design of an integrated vacuum chuck with variable hole density and active temperature control (Fig. 2), surface figure accuracy better than 4λ (λ=632.8 nm) and sub-nanometer roughness [root mean square (RMS)=0.59 nm] were achieved on large-aperture KDP crystals.Surface defects induced by fly-cutting, such as brittle indentations, cracks, protrusion pressure points, ballast, and plastic scratches, were systematically characterized (Fig. 4). Fluorescence microscopy (405 nm) revealed that defects like brittle indentations, cracks, protrusions, and ballast exhibit higher fluorescence intensity than defect-free regions, indicating stronger laser energy absorption and lower LIDT (Fig. 5, Table 1). An explosion simulation model was innovatively proposed to quantify the damage thresholds for different defect types and to elucidate the underlying damage mechanisms (Fig. 8). This model simplifies the complex multi-field coupling problem into a quantifiable explosive process, revealing that local mechanical strength and absorption capability are key factors affecting LIDT.Sub-nanosecond laser conditioning: the mechanisms underlying laser conditioning for the elimination or passivation of both point defects and structural defects were elucidated. A pulse width of 500 ps was identified as the optimal parameter within the 300?800 ps range, as it provides sufficient peak power for electronic excitation while exceeding the lattice heat transfer time necessary for thermal effects. After applying this offline conditioning process to 400 mm aperture DKDP crystals, under ultraviolet laser irradiation, the surface damage density was reduced from 5.02 to 0.55 pp/cm2, and the bulk damage density decreased from 2?3 to 0.3?0.8 pp/mm3 (Fig. 10, Table 2), marking a critical step toward engineering application.Sol-gel coatings: to enhance environmental stability and optical performance, multifunctional coatings were developed via sol-gel methods.Moisture barrier coatinga novel network-ball embedded structure was created by embedding hexamethyldisilane (HDMS)-modified SiO2 nanoparticles into a siloxane polymer matrix (Fig. 11). This structure yields a tunable refractive index (1.21?1.44), high hydrophobicity (contact angle increased to 109.4°), and exceptional moisture resistance (less than 0.1% transmission loss after 27 weeks at 80% relatively humidity).Antireflective (AR) coating: using methyltriethoxysilane (MTES) to seal surface pores after HMDS modification, an AR coating with low residual reflectance (less than 0.5%@355 nm), high LIDT (more than 20 J/cm2), and excellent oil contamination resistance (only 0.097% transmission drop after 20 weeks) was achieved (Fig. 12).Bilayer coating systema precisely designed bilayer system for dual-wavelength (527 nm & 351 nm) antireflection was realized. It combines a high-refractive-index moisture barrier layer and a low-refractive-index AR layer, exhibiting outstanding optical uniformity and environmental stability (0.7% transmission drop after 19 weeks in high humidity) (Fig. 13).Conclusions and ProspectsThis review comprehensively summarizes recent breakthroughs in ultra-precision manufacturing technology for large-aperture KDP/DKDP crystals achieved through an integrated process route. Significant advances in fly-cutting theory and equipment, defect characterization and suppression, laser conditioning, and functional coating design have collectively and notably enhanced the surface accuracy, laser damage resistance, and environmental stability of these critical optical components. Looking forward, future research should prioritize several key directions: 1) exploring novel processes such as ultra-precision polishing to further suppress mid-spatial-frequency ripples induced during machining; 2) developing multifunctional composite coatings that exhibit lower curing temperatures, higher LIDT, and extended operational lifetimes; and 3) establishing a full-process database that correlates manufacturing defects with damage performance, along with developing efficient, non-destructive online evaluation techniques for comprehensive performance assessment of large-aperture crystal components.

SignificanceMid-infrared lasers operating in the 3?5 μm spectral band exhibit critical application value in spectroscopy, environmental monitoring, biomedical engineering, optical communications, and photoelectric countermeasures. This importance stems from their high atmospheric transmission within the atmospheric window and spectral alignment with numerous molecular absorption peaks, establishing them as a key research focus in laser technology. As one of the primary approaches for generating such lasers, optical parametric oscillators (OPOs) traditionally rely on discrete optical components, resulting in complex systems with limited potential for miniaturization. The revolutionary significance of self-optical parametric oscillation (SOPO) implemented through Nd3+-doped periodically poled neodymium-doped magnesium oxide-doped lithium niobate (Nd∶MgO∶PPLN) crystals lies in the monolithic integration of laser gain and OPO frequency conversion within a single gain medium. This breakthrough has opened up new avenues for developing compact, efficient, high-power all-solid-state mid-infrared lasers, garnering significant and sustained attention from both academic and industrial communities in recent years.ProgressThis paper systematically reviews research progress in mid-infrared self-optical parametric oscillator (SOPO) technology, with particular emphasis on Nd∶MgO∶PPLN crystal-based systems. It introduces the optical characteristics of neodymium-doped magnesium oxide-doped lithium niobate (Nd∶MgO∶LN) crystals, including polarization-dependent absorption spectra (Fig. 1(a)) and fluorescence emission profiles (Fig. 1(b)), along with their energy-level structure (Fig. 2). It elaborates how Nd3+ doping confers fundamental wave gain capability, while periodic poling enables efficient nonlinear frequency conversion, synergistically forming the physical foundation for Nd∶MgO∶PPLN as a self-frequency-converting crystal. The evolutionary trajectory spans from early dye-laser-pumped 1085 nm fundamental wave output to contemporary high-power, high-efficiency continuous-wave and pulsed 1084 nm/1093 nm outputs under laser diode (LD) pumping. Pivotal breakthroughs focus on suppressing thermally induced 1093 nm non-phase-matched polarized emission to achieve exclusive π-polarized 1084 nm fundamental light generation through innovative strategies, including thermally boosted pumping, multi-focus coupled pumping, and pulsed pumping techniques.Following the establishment of a high-quality fundamental light foundation, research focus has shifted toward optimizing frequency-converted output performance and characteristics through poling period design. Our research group has successively reported laser emissions covering critical application bands: the 1.5 μm eye-safe band, 2.1 μm molecular detection band, and 3.8 μm atmospheric window band, with targets on high power, high single-pulse energy, narrow linewidth, and programmable control. Representative achievements detailed include:(1) In the 1.5 μm band: 15.3 μJ pulses at 1512 nm under a 60 kHz repetition rate were achieved via dual-end pumping with intracavity acousto-optic Q-switching; 183 mW output at 1514 nm signal wave was obtained using multi-focus coupled pumping for thermal management during dual-spot pumping.(2) In the 2.1 μm band: degenerated 1.21 W output at 2168 nm was realized through intracavity acousto-optic (AO) Q-switching combined with optimized poling period design, followed by narrow-linewidth laser generation via Fabry?Pérot (FP) etalon integration.(3) In the 3.8 μm band: 3.04 W idler output at 3814 nm was obtained through pulse pumping combined with passive Q-switching; programmable pulse-burst generation was enabled by step-active Q-switching; 1.59 W average power output at 3834.3 nm under 28.4 W pump power (with wavelength stability and a tuning range of 29.4 nm) was yielded by thermally boosted pumping integrated with Cr∶YAG passive Q-switching and thermoelectric cooler (TEC) precision thermal control.This section culminates in a comprehensive developmental summary of Nd∶MgO∶PPLN crystal-based self-OPO technology, additionally reporting recent breakthroughs in pulse-pumped electro-optic (EO) Q-switched mid-infrared SOPO. Here, microsecond pulse pumping ensures full-range π-polarized 1084 nm fundamental light output, enabling stable mid-infrared idler generation through integrated electro-optic Q-switching—thus paving the way for miniaturized high-single-pulse-energy mid-infrared SOPO systems.Conclusions and ProspectsIn summary, self-optical parametric oscillator (SOPO) technology is progressively cementing its position as an indispensable methodology for mid-infrared laser generation, unlocking transformative pathways toward the realization of compact, lightweight, and high-power all-solid-state mid-infrared laser systems. The research trajectory demonstrates a coherent evolutionary logic: initial endeavors concentrated exclusively on attaining fundamental wavelength emission, subsequently advancing toward mitigating crystalline thermal effects to achieve precise polarization control of fundamental light, and upon establishing a robust foundation for fundamental wave performance, strategically pivoting toward optimizing quasi-phase-matched frequency-converted outputs for superior characteristics and enhanced functionality. Through meticulous poling period engineering, our research team has successively attained laser emissions spanning strategically critical spectral bands—specifically the 1.5 μm ocular-safe region, the 2.1 μm molecular fingerprint detection window, and the 3.8 μm atmospheric transmission band—while relentlessly pursuing performance benchmarks encompassing elevated power thresholds, augmented single-pulse energy densities, spectral linewidth narrowing, and programmable operational control.Notwithstanding these advancements, persistent challenges endure in practical deployment scenarios, notably insufficient suppression of thermally induced crystal distortions and limitations in further scaling pulse energy magnitudes. Future investigative priorities will emphasize enhancing systemic stability and amplifying output power metrics. Building upon extant SOPO experimental frameworks, the integration of miniaturized solid-state lasers as spatially optimized pumping sources presents a viable strategy for augmenting system compactness and functional integration. Capitalizing on the cognate electro-optic properties shared by Nd∶MgO∶PPLN and conventional lithium niobate (LN) crystals, experimental configurations could exploit Nd∶MgO∶PPLN to manifest intrinsic self-electro-optic Q-switching capabilities. Subsequent research initiatives should comprehensively explore the latent potential of Nd∶MgO∶PPLN crystalline platforms, with dedicated efforts directed toward developing multifunctional monolithic architectures that synergistically integrate pumping, optical gain, and Q-switching modalities within unified Nd∶MgO∶PPLN substrates—thereby catalyzing sustained technological progression of SOPO systems across academic research and engineering applications.