View fulltext

View fulltext

Sn 4+ in the LiSn2(PO4)3 compound was doped with Cr 3+ ion. Single phase of α-LiSn2(PO4)3 can be obtained with the Cr 3+ contents x=0.1-0.3 for the as-prepared Li1+xCrxSn2-x(PO4)3 samples, which were confirmed by X-ray diffraction (XRD) measurement. Further augment of the Cr 3+ content led to the precipitation of a little secondary phase such as SnO2. Although the introduction of Cr could not prevent the LiSn2(PO4)3 from decomposition during initial discharging, the sample with Cr 3+ content of 0.3 showed remarkably enhanced electrochemical performances. Specific discharging capacities of 403.1 and 241.9 mAh/g could be delivered at current densities of 100 and 800 mA/g after 25 cycles, respectively. Improvement in electrochemical performance could be attributed to the steric effect of complex matrix composed of Li3PO4 and Cr, which was favorable for preventing Sn particles from aggregation during subsequent charge/discharge cycles, Leading to promote utilization efficiency of the precipitated Sn.

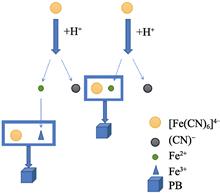

Prussian blue (PB) is a kind of metal-organic framework complex that displays wide application prospect as cathode material for aqueous sodium-ion batteries. In this study, PB composites were prepared by a single source method. Furthermore, effects of reaction temperature, time and concentration of hydrochloric acid on PB morphology and electrochemical performance were systematically investigated. The results showed that crystallinity and electrochemical stability of PB were improved by increasing reaction temperature. The aqueous sodium-ion battery with PB synthesized at 80 ℃ as cathode material displayed a capacity retention of 93.9% after 100 cycles. The particle size of PB grew with the extension of reaction time until 6 h. It’s exhibited that the extended reaction time was beneficial to the cycle performance of device fabricated with PB prepared for 10 h, delivering 90% capacity retention after 100 cycles. Increment of the hydrochloric concentration acid changed the surface morphology, and thus improved electrochemical performance of PB. When the concentration of hydrochloric acid reached 0.20 mol/L, a capacity of 67.5 mAh/g could be maintainted after 100 discharge-charge. This work may provide theoretical and experimental gaidence for preparing high performance PB-based aqueous sodium-ion batteries.

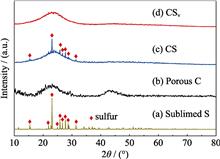

Lithium sulfur battery has attracted extensive attention as highly promising next generation of rechargeable battery. However, lithium sulfur battery, especial the sulfur cathode, is still under experimental exploration, and the commercial carbon fiber felt is rarely reported to apply in the sulfur cathode. Herein, the flexible carbon-fiber- supported carbon-sulfur electrode was prepared, and its physical properties and electrochemical performance were characterized. The results showed that the interface resistance was reduced from 97.9 Ω to 22.6 Ω, due to porous three-dimensional network of the carbon fiber felt and micropore of the porous carbon which benefited energy density of the battery and conductivity of the sulfur cathode. Furthermore, the initial discharge capacity at 0.05C rate was 996.7 mAh/g and the discharge capacity at 2C rate after 140 cycles was 666.7 mAh/g when carbon fiber felt serves as current collector, while their counterparts with aluminum foil as the current collector were 772.9 and 471.6 mAh/g, respectively. Furthermore, the environmental-friend and low-cost binder LA132, super-P, and the ball-milling technique are beneficial to mass synthesis, suitable for the industrial production and the application of lithium sulfur battery.

(Li0.5Ce0.25La0.25)xCa1-xBi2Nb2O9 Aurivillius phase ceramics were prepared via conventional solid-state sintering route. The effects of co-substitution with different types of rare-earth elements on crystal structure, microstructure and electric properties were investigated. Rietveld-refinement analysis showed that the multiple rare earth elements embedded into the lattice point and formed corresponding solid solutions. The crystal structure tended to transform to tetragonal system from pristine orthorhombic system, whereas Bi 3+ in A-site with 6s2 lone pair electrons suppressed this change. SEM images exhibited that the grain growth in the direction perpendicular to the c-axis was restrained, which could be attributed to the rare earth oxides’ high melting point and low diffusion during the sintering process. Morphotropic phase boundary of a glide plane between orthorhombic system and pseudo-tetragonal system vanished, which generated spontaneous polarization along a and b axis and resulted in increase of piezoelectric properties. The obtained (Li0.5Ce0.25La0.25)0.17Ca0.83Bi2Nb2O9 ceramics performed optimal piezoelectric properties (d33=16.4 pC/N, Tc=913 ℃) and exhibited excellent thermal stability, remaining 85.4% of their initial d33 values after annealing at 850 ℃ for 2 h. All above results demonsrated that the multidoped materials are promising candidates for ultrahigh temperature applications.

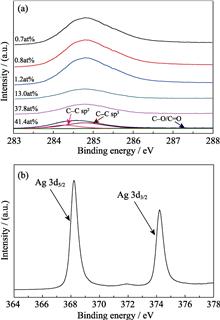

By adjusting sputter current from 1.3 A to 2.0 A in reactive magnetron sputtering deposition processes, Ag doped amorphous carbon films (a-C:Ag) with doping content from 0.7at% to 41.4at% were prepared. The influence of Ag content on structure, component, mechanical and electrical properties of a-C:Ag films were systematically studied. The results showed that Ag atoms were dissolved in amorphous carbon matrix at low Ag content (0.7at% to 1.2at%) conditions. However, Ag nanocrystal with a size around 6 nm formed when Ag content increased to 13.0at%. With the increase of Ag content, the size of sp 2 clusters in the amorphous carbon matrix increased while the structural disorder degree decreased. Stress test indicated that in the low Ag content range, Ag atoms were dissolved in carbon matrix which played a pivotal role in promoting relaxation of bond length and angle distortion, thereby the film stress was reduced. Ag atoms started to form Ag nanocrystals as the Ag content increased. As a result, film stress would be reduced due to release of excessive distortion by sliding and diffusion at the grain boundaries. When Ag content reached 37.8at%, a-C:Ag exhibited transition from metal to semiconductor characteristic near 11.6 K. However, as the Ag content increased to 41.4at%, the films displayed semiconducting characteristics in the whole test temperature range (2-400 K) and exhibited typical thermal activation mechanism within temperature range of 164-400 K.

Due to the different vapor pressures between SrO and ZrO2, composition of air plasma sprayed (APS) SrZrO3 coating deviates from stoichiometric SrZrO3, resulting in formation of second phase ZrO2 in the as-sprayed SrZrO3 coating. To obtain single-phase coating with high phase stability, the Sr1.1(Zr0.9Yb0.05Gd0.05)O3.05 powder with excess Sr was synthesized by solid state reaction and spray drying, followed by air plasma spray to obtain the Sr1.1(Zr0.9Yb0.05Gd0.05)O3.05 coating. Thermo-physical properties and thermal cycling behavior of the Sr1.1(Zr0.9Yb0.05Gd0.05)O3.05 coating were investigated. Experimental results showed that the Sr1.1(Zr0.9Yb0.05Gd0.05)O3.05 coating had no second phase and showed a good high-temperature phase stability after heat- treatment at 1600 ℃ for 360 h. The sintering rate of the as-sprayed Sr1.1(Zr0.9Yb0.05Gd0.05)O3.05 coating was 7.27×10 -6 s -1. Thermal expansion coefficients (TECs) and thermal conductivity of the coating after heat-treatment at 1600 ℃ for 360 h were (9.0-11.0)×10 -6 K -1 (200-1400 ℃) and 2.83 W/(m∙K) (1000 ℃), respectively. Thermal cycling lifetime of the Sr1.1(Zr0.9Yb0.05Gd0.05)O3.05/YSZ double ceramic layer coating was 1000 cycles, due to failure occurring in the Sr1.1(Zr0.9Yb0.05Gd0.05)O3.05 coating. Moreover, singe-phase Sr1.1(Zr0.9Yb0.05Gd0.05)O3.05 coating with SrZrO3 structure could be prepared by adding excess SrO in the feedstock, which showed higher TEC by co-dopping with Yb2O3 and Gd2O3 and sintering resistance than did the SrZrO3 coating. However, the thermal conductivity of the Sr1.1(Zr0.9Yb0.05Gd0.05)O3.05 coating is higher than that of the SrZrO3 coating because of the absence of the second phase.

A kind of hexagonal boron nitride nanosheets (BNNSs) with high crystallinity was synthesized using magnesium borate nanosheets with petal morphology as the template and boron source while ammonia as the nitride source. The morphology and structure of the BNNSs were analyzed by SEM, TEM, XRD, Raman, and FT-IR. The results show that the BNNSs are a kind of single crystalline h-BN with a thickness of about 5 nm and a diameter of 150-300 nm, respectively. The BNNSs aggregate together and inherit the petal shape of magnesium borate. Then, BNNSs/polyvinyl alcohol (PVA) composite films containing different content of BNNSs were prepared. The results show that elastic modulus of the film containing 30% BNNSs is 39.8% higher than that of pure PVA films, while the in-plane thermal diffusivity and thermal conductivity increase about 7 and 8 times, respectively, demonstrating the significant improvement to the thermal performance of PVA by adding this kind of BNNSs.

A kind of graphene composite (rGO/Co0.5Zn0.5Fe2O4) was synthesized with the graphene oxide (GO) prepared from natural flake graphite and cobalt-zinc ferrite (Co0.5Zn0.5Fe2O4) manufactured by the hydrothermal method. The structure of composites was characterized by X-ray diffraction (XRD), Raman spectrometer (Raman) and the Fourier-transform infrared spectroscopy (FT-IR). Morphology, electromagnetic loss properties, Debye relaxation, and microwave absorbing properties of rGO/Co0.5Zn0.5Fe2O4 were investigated by transmission electron microscope (TEM) and vector network analyser (VNA). Sharp peak of graphene oxide was changed from 2θ=9.74° to 24.15° in the XRD patterns and the oxygen functional group disappeared after the composite reaction, which demonstrated that GO was successfully reduced to rGO. The graphene was embedded with cobalt-zinc ferrite, observed by transmission electron microscope, with its dispersion worse with the loaded Co0.5Zn0.5Fe2O4 increasing. Absorbing property of rGO/Co0.5Zn0.5Fe2O4 composite prepared with w(Co0.5Zn0.5Fe2O4) : w(GO)= 2 : 1 is the best with the minimum reflectivity of -36.89 dB at 15.11 GHz and the effective absorption frequency bandwidth of 3.74.

This study investigated the bioactivity and mechanical stability of hydroxyapatite (HA) ceramics under micro-vibration stress environment (MVS), and explored influence of physiological stress environment on osteoinductivity of HA ceramics. Results of scanning electron microscopy (SEM) and calcium ion release showed that MVS was beneficial for calcium ion re-deposition and bone-like apatite layer formation in HA with high micro-porosity ((29±1.2)%, (26.4±0.3)%, respectively), while calcium ion release of HA materials with a lower micro-porosity ((10.6±0.8)%) was promoted. Protein adsorption results displayed that 40 Hz MVS promoted while 60 Hz MVS significantly inhibited HA protein adsorption behavior. The compression tests demonstrated that stress environment of MVS did not affect the mechanical stability of the HA scaffolds. Our results suggested that stress environment is an important factor affecting the bioactivity and osteoinductivity of HA ceramics.

Photocatalyst of N-doped Bi2O2CO3 (N-BOC)/CdSe quantun dots (QDs) composite was sucessfully prepared for degradation of nitric oxide (NO), an indoor air pollutant. The results of X-ray diffraction, transmisssion electron microscopy and X-ray photoelectron spectroscopy showed that after combination with CdSe QDs structure and morphology of N-BOC remained the same as before combination. Photocatalytic degradation of NO showed that introduction of CdSe QDs significantly enhanced the removal ratio of NO. Moreover, the generating ratio of toxic byproduct NO2 decreased to 1%, which indicated efficient inhibition for the toxic byproduct generation. From UV-Vis absorption spectroscopy and photoluminescence spectroscopy, the CdSe QDs showed promotion on light absorption, and inhibition of charged recombination of photo-induced carriers. More importantly, only signals of NO3- were captured in in situ DRIFTS measurements, whilst the signals from NO2 could be barely detected during photocatalytic process. Superoxide radicals (O2-) and holes (h +) are considered to be possible active species in the reaction, which dominate the oxidation process from NO to NO3-.

La2O3-TiO2-ZrO2 glass has great potential applications in lens and upconversion host materials for its ultrahigh refractive index. However, due to its low glass forming ability, it can only be prepared by some extremely rapid melt cooling method, which is hard to produce large-sized materials. On the basis of amorphous plastic behavior above the glass transition temperature Tg, large-sized La2O3-TiO2-ZrO2 bulk glasses were obtained by hot pressed sintering within the thermodynamic window ΔT. 30.8% LaO3/2-59.2% TiO2-10% ZrO2 amorphous spheres were firstly prepared by aerodynamic levitation furnace. Whereafter, these spheres were smashed and ground into powders. Then these glass powders were hot pressed into a bulk glass with dimension of ϕ20 mm×1 mm. The effects of sintering temperature and pressure on the process of hot pressed sintering were investigated. Microstructures and phase compositions of samples were studied by SEM and XRD. The results show that the samples sintered above 910 ℃ contain a few La4Ti9O24 crystal phases, while the samples sintered below 900 ℃ are totally amorphous. When the sintering temperature is below 900 ℃, the increase of sintering temperature in a certain range can reduce the number of pores apparently to improve the density of samples. And with the increase of pressure from 20 MPa to 60 MPa, the density of bulk glass prepared by hot pressing at 900 ℃ increases from 4.8797 g/cm 3 to 5.1178 g/cm 3. The large-sized La2O3-TiO2-ZrO2 glass displays excellent optical performance with refractive index of 2.33 at the wavelength of 587.6 nm and the abbe number of 13.2. By analyzing the shrinkage curve of the samples, it is confirmed that the plastic flow is the main mass transfer way during densification process.

Aluminum nitride (AlN) was synthesized by direct combustion of spherical Mg-Al alloy powder in air. The alloy (Al12Mg17) heaped up within a heating area (1 cm in diameter) and was ignited by butane flame. Synthetic process was recorded by a high-speed camera. Morphology and phase makeup of initial powder and combustion products were analyzed by scanning electron microscope and X-ray diffraction. Thermodynamic property of the alloy was analyzed using TG-DSC. The results show that the Al in the Mg-Al alloy powder can be completely transformed to AlN. Ignition temperature of the alloy is about 494.4℃. Once the alloy powder is ignited, self-sustained combustion in the powder can be observed. When combustion begins, Mg can rapidly vaporize and react with oxygen. This oxidation reaction can consume the oxygen around the particles, leading N2 diffusing to the liquid Al layer. Combustion products of the alloy consist of two different layers.The upper white layer contains only MgO and the lower black layer contains only AlN. During synthetic process, the existence of Mg significantly promotes the nitridation of Al.

Silicon has the highest theoretical lithium insertion specific capacity, more than ten times the theoretical specific capacity of graphite electrode material, and low delithiation potential, with abundant resources and good rate characteristics, high-energy-density lithium-ion battery silicon-based materials have become hot spots in application fields such as electric vehicles and renewable energy storage systems. However, it will cause powdering and structural collapse of the silicon electrode material due to its large volume expansion effect in the process of delithiation and lithium insertion. In addition, the solid electrolyte interface (SEI) layer on the surface of silicon is repeatedly formed in the electrolyte, which increases the polarization and reduces the coulomb efficiency, eventually leading to deterioration of electrochemical performance. In order to solve the above problems and realize the commercial application of silicon electrodes. This paper systematically summarizes the work to solve the volume effect in charge and discharge process through the selection and structural design of silicon-based materials, and deeply analyzes and discusses the preparation methods, electrochemical properties and corresponding mechanisms of representative silicon-based composite materials, focusing on silicon-carbon composites and SiOx (0x≤2) based anode materials. Finally, the problems of silicon-based anode materials are analyzed and their prospects are prospected.