In order to solve the problem of low recognition accuracy of aero⁃engine lockwire caused by factors of the complex background, uneven illumination and small percentage of the target region, this paper proposes an improved mask region⁃based convolutional neural network (Mask R⁃CNN) model for lockwire instance segmentation. Firstly, the gamma corrections of R, G and B channels with different degrees were carried out to transform the lockwire image into pseudo⁃color image and enhance the contrast. Then, the dynamic snake⁃shaped convolution was incorporated into Resnet, the backbone network of Mask R⁃CNN, to make the network to adaptively focus on the slender and curved local structure during feature extraction. Then, based on the geometric features of the fuse's slender curve, dynamic snake convolution was integrated into the backbone network Resnet of Mask R⁃CNN, allowing the network to adaptively focus on the local structure of the slender curve during feature extraction. Finally, the CBAM attention mechanism was introduced in the feature fusion phase to retain the shallow features of small target, so as to improve the perception ability of the network on small target. The experimental results showed that the AAP50 of the improved module mask reached 82.54%, which was improved by 5.83% compared to basic mode. This study provides strong support for digital and intelligent detection of aero⁃engine lockwire.

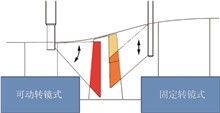

Due to the strong background radiation inside the aero engine, there is a large deviation between the temperature value obtained by measuring the surface of the turbine blade using the conventional radiation temperature measurement system and the actual temperature value. To address this issue, a new generation of turbine blade surface temperature measurement system was developed based on the principle of multispectral temperature measurement. The system uses movable mirror probes and fixed mirror probes to achieve high⁃reliability scanning, realizes efficient signal acquisition and precise control of equipment through high⁃speed multi⁃channel synchronous signal acquisition and control system, and realizes online measurement and reconstruction of three⁃dimensional temperature field on the blade surface by using multispectral temperature measurement modeling in complex thermal environment, multi⁃view three⁃dimensional temperature field reconstruction and other technologies. The performance indexes of the multispectral turbine blade surface temperature field measurement system were tested by using a blackbody radiation source and a dynamic calibration device, and the results showed that the system could achieve real⁃time online measurement of the surface temperature of turbine blades at 550 ~ 1 500 ℃, and the maximum allowable error did not exceed ± 7.5 ℃, which met the temperature measurement requirements of turbine blades. The research results provide strong support for promoting the development of thermal parameter testing technology for aeroengine turbine blades in high⁃temperature and complex environments.

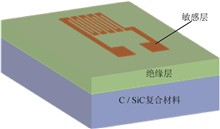

A thin film strain gauge fabrication method was proposed based on high⁃temperature inorganic glue flattening treatment, magnetron sputtering technology and atomic layer deposition (ALD), aiming at solving the problem of high⁃temperature strain measurement on the surface of C / SiC composite materials. The surface of the C / SiC composite material was flattened by brushing inorganic glue, and then a thin film strain gauge consisting of a Pt sensitive layer and a composite insulating layer was prepared using magnetron sputtering and atomic layer deposition technology. Specifically, the Pt sensing layer was prepared by direct current (DC) sputtering through complex surface patterning technology with a hard⁃mask, achieving a resistance of 75 Ω and a thickness of 450 nm. For the insulating layers, three types of composite insulating layers (YSZ / Al₂O₃, Al₂O₃⁃YSZ / Al₂O₃, and HfO₂⁃YSZ / Al₂O₃ composite layers with a thickness of 1.2 μm) were prepared via DC sputtering and atomic layer deposition. A comparative study was emphatically conducted to evaluate the high⁃temperature insulation performance of the three insulating layers. The results indicated that the HfO₂⁃YSZ / Al₂O₃ composite insulating layer exhibited the best performance, with an insulation resistance of 32.94 kΩ at 950 ℃ after multiple thermal cycles. Strain testing under a temperature range from room temperature to 600 °C revealed that the Pt strain gauge fabricated based on HfO₂⁃YSZ / Al₂O₃ composite insulation layer achieved a maximum gauge factor (GF) of 2.93. The minimum and maximum measurement errors were 0.01% (600 °C, 133.2 με) and 6.49% (200 °C, 133.2 με), respectively. The strain gauge exhibited superior high temperature stability and strain response. The research results provide a new technical solution for high⁃temperature strain measurement on the surface of C / SiC composite materials, which possessed positive significance for promoting the development of high⁃precision strain measurement technology for thermal structural components of hypersonic vehicles.

When using pressure pipeline for measuring high⁃temperature pulsating pressure in aircraft engines, high⁃temperature condensed water may cause a state of "gas mixed with liquid" in the pressure pipeline, and using traditional dynamic models of gas medium pressure pipeline for analysis may result in significant errors. In response to this issue, a transfer function of the pressure pipeline under the condition of "gas mixed with liquid" was established based on a compressible fluid pressure pipeline system model. Pressure pipelines of the same length but different inner diameters were selected, and experimental research was conducted under different gas⁃liquid mixing states by adjusting pressure and gas⁃liquid ratio. The relationship between the dynamic characteristics of the pressure pipeline and gas⁃liquid ratio was obtained, and the differentiated features of the dynamic characteristics of the pressure pipeline after gas⁃liquid mixing under different pipe diameters were obtained. This lays the foundation for the subsequent research on the dynamic characteristics of the pressure pipeline under other complex medium conditions, and provides technical reference for improving the accuracy of dynamic pressure testing of aviation engines.