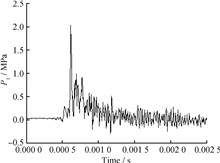

The article reviews the key parameter testing technologies for air⁃breathing pulse detonation engines under unsteady combustion conditions. It elaborates on the methods for measuring detonation wave pressure and gas velocity, explores the research status of piezoelectric and piezoresistive sensors as well as optical technologies, and analyzes the challenges faced by these technologies in high⁃temperature and high⁃frequency environments. The current state of the research on the measurement of pressure ratio and combustion efficiency is analyzed, and high⁃precision measurement schemes based on the mass⁃weighted average method and optical technologies are discussed. Dynamic testing methods for turbine speed and efficiency are introduced, the reasons for turbine efficiency decline under unsteady conditions are analyzed, and the design optimization suggestions are proposed. The latest advancements in thrust measurement technologies are summarized, and the high⁃precision thrust measurement methods based on dynamic system parameter identification and deconvolution techniques are elaborated. Finally, the future development directions of unsteady parameter testing technologies for pulse detonation boosted engines are envisioned, including improving the anti⁃interference capability of sensors and optical devices, optimizing combustion chamber design, developing dynamic testing systems with higher temporal and spatial resolution, and researching more intelligent multi⁃parameter integrated measurement systems. These efforts aim to further enhance the accuracy and reliability of unsteady parameter testing technologies for pulse detonation boosted engines and promote their engineering applications.

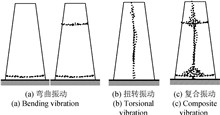

Blade vibration parameters are crucial for influencing the operational efficiency and safety of major rotating equipment such as aero⁃engines and gas turbines. The blade vibration measurement method based on blade tip timing has become a standard technology for monitoring the health status of rotating blades. This article introduces the principle of blade tip timing measurement, describes the typical structure of the system and common measurement processes, and summarizes four key technologies of blade tip timing measurement, including high⁃precision extraction of blade arrival time, high signal⁃to⁃noise ratio blade vibration displacement measurement, extremely under⁃sampled blade vibration parameter identification, and blade fault diagnosis based on small⁃sample tip timing signals. It analyzes in detail the significant progress made in blade tip timing measurement methods in terms of blade tip timing sensing technology, vibration parameter identification technology, and blade fault diagnosis technology. It proposes the development trend and prospects of blade tip timing technology, and summarizes the future key research directions in the field of non⁃contact blade vibration measurement from four aspects: sensing signal multiplexing, uncertainty analysis and calibration, on⁃board application of systems, digital twin and intelligent operation and maintenance. It is expected to provide important references for the scientific development and engineering application of blade tip timing measurement technology.

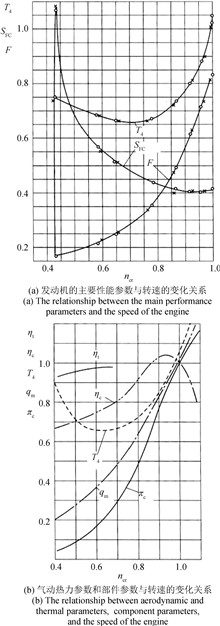

From the perspective of performance and reliability testing, this paper analyzes the testing requirements for the engine⁃level test of gas turbine engine, and identifies the key parameters, including thrust, power, speed, flow rate, temperature, pressure, and vibration. The principles, applications, and development trends of the relevant testing techniques for each parameter are introduced. For thrust and power measurement, the structure of thrust measurement bench and power measurement system, along with their calibration methods, are described. In terms of rotational speed measurement, typical speed measurement systems and strategies for dealing with signal distortion are presented. Regarding flow rate measurement, velocity, differential pressure, and mass flow meters used for fuel flow measurement, as well as the structure and measurement point arrangement of the intake air flow measurement section are discussed. For temperature measurement, gas temperature measurement and wall temperature testing methods encompassing resistance temperature detectors, thermocouples, temperature⁃indicating paint, fluorescent temperature measurement, and radiation temperature measurement techniques are introduced. In pressure measurement, the pressure testing system is described, and the challenges and solutions for dynamic pressure testing in high⁃temperature environments are analyzed. In vibration measurement, the engine⁃level vibration testing system and the issues related to vibration measurement point arrangement are discussed. The testing techniques for the key parameters of gas turbine engine are expected to evolve towards higher accuracy, higher frequency response, and higher temperature tolerance. Meanwhile, the engine⁃level testing systems will tend towards intelligence and integration.

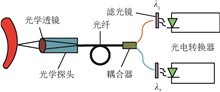

Compared with the traditional temperature measurement technology, radiation thermometry technology offers the advantages of non⁃contact measurement, fast response and excellent high⁃temperature adaptability. It enables real⁃time measurement of the surface temperature distribution of key components such as turbine rotor blades. It introduces the basic principles, technical characteristics and application scope of various radiation temperature measurement methods including brightness thermometry, colorimetric thermometry, charge⁃coupled device (CCD) thermometry, and multi⁃wavelength radiation thermometry. The application and development status of radiation thermometry technology in turbine blade temperature measurement are described, and the future development direction of this technology is discussed. It is pointed out that the accuracy and reliability of radiation thermometry technology can be further improved by optimizing the design of optical probe, using more advanced algorithms, and applying new type of high⁃temperature⁃resistant materials; and that the radiation thermometry technology can be combined with thermocouple thermometry technology to build a more precise and stable turbine blade temperature monitoring system.