View fulltext

View fulltext

Ceramics are a series of inorganic nonmetallic materials with a long history and has been extensively used. They have been playing a vital role in the human civilization process. Nowadays, as one of the three pillars in the material systems for modern industry, ceramics with excellent physical and chemical properties have been increasingly used and researched and become indispensable in the high-tech application fields such as machinery and electronics, energy and environmental protection, aerospace and biomedical industries, especially for the advanced ceramics with complex and integrated structural and functional properties. However, due to their inherent high hardness and brittleness, when manufacturing ceramic products with highly complex three-dimensional shapes or customized structures and functions, the traditional molding and machining technologies often face certain technical limitations with great difficulty and long production cycle. The emergence of additive manufacturing (AM) paves a new way to break through above limitations. AM technology is earliest known as freeform fabrication (FFF) or rapid prototyping (RP) technology, and was gradually popular with the general public and is now commonly known as 3D printing technology in this century. ‘Stereolithography (SL)’ photopolymerization additive manufacturing technology suitable for organic resin solutions and ‘Selective Laser Melting (SLM)’ additive manufacturing technology for metal powders, were invented in the US and Germany in the 1980s and 1990s, respectively. These two epoch-making technologies are the most significant representatives of all AM technologies. At present, over ten types of additive manufacturing technologies have been developed for various raw materials. However, compared with organic and metallic materials, ceramics generally possess lower physical and chemical activities and higher melting points; some AM processes used for organic and metallic materials cannot be directly applied to ceramic materials. Nevertheless, currently most of the ceramic AM technologies are derived from that made for organic and metallic materials. This makes the development of AM technologies for ceramic materials difficult, and thus its development history is relatively shorter. However, the magic and charm of AM lie in its unique flexibility of manufacturing highly complex shapes, as well as the advantages of customized structures and functions, which extensively attract worldwide researchers to investigate AM of ceramic materials and their applications. In recent years, a number of excellent research groups and industrial organizations have sprung up in the field of ceramic AM. According to the statistics preliminary generated from the 1st National Forum on Additive Manufacturing of Ceramics (FAME2021) initiated by Prof. CHEN Zhangwei of Shenzhen University in July 2021, there are approximately over 60 institutes in China specializing in the research of ceramic AM and applications, while more than 20 industrial manufacturers are involved in the development and fabrication of materials, printing process equipment, and post-processing equipment that are relevant to ceramic AM technology. Among them, the majority of research focuses on the AM of photopolymerization (including SL and Digital Light Processing (DLP)) or Direct Ink Writing (DIW) using the mixtures of ceramic powders and resins/adhesives. The rest mainly utilizes ceramic powders and high-power lasers such as Selective Laser Sintering (SLS), Laser Directed Energy Deposition (LDED), and other processes for direct AM of ceramics. In terms of the types of ceramic materials involved, most research focuses on oxide ceramic materials, such as SiO2, ZrO2, Al2O3, and their mixed or multiphase materials, as well as PZT, BTO, TCP, and other advanced ceramics. The main application directions include load-bearing components and functional parts, such as catalytic carriers, casting molds, heat insulation, piezoelectric, sensors, artificial bones, dentistry, ultra-high temperature parts, optics, and other fields. Besides, in recent years, researchers have also turned to AM of non-oxide ceramics such as SiC, Si3N4, AlN, and even more complex Polymer-Derived Ceramics (PDCs) that generate polynary ceramics, and substantial progress has been achieved. In general, the ceramic AM processes take ceramic-based materials as ‘inks’ and focused energies such as light energy, mechanical energy and heat energy as ‘pens’, to ‘draw’ a variety of complex ceramic devices with integrated structures and functions, which is similar with the Chinese fairy tale of ‘Ma Liang the Magic Brush’. It is noteworthy that the outcome of ‘Ma Liang the Magic Brush’ was ‘What You Draw Is What You Get’. In our opinion, this is exactly the ultimate goal of AM or 3D printing, namely ‘What You Print Is What You Get’. There are still numerous challenges to overcome to achieve ‘What You Print Is What You Get’ in the field of ceramic AM. Due to the complicated material properties of ceramics, the process of shaping by various AM technologies involves the preparation of the material feedstock systems, the adaptation of forming process, and the optimization of heat treatment and post-treatment process. Therefore, material selection and controls over the forming process, deformation and defect, structures and properties, and other aspects require overall investigation and careful balance. In the second half of 2021, while the conference of FAME2021 was held, the Editorial Board of the Journal of Inorganic Materials invited Prof. LU Jian from the City University of Hong Kong (CUHK) and Prof. CHEN Zhangwei from Shenzhen University (SZU) as guest editors to organize this Special Issue (SI) themed ‘Additive Manufacturing of Inorganic Materials’. Prof. WU Jiamin from Huazhong University of Science and Technology (HUST) also contributed to the organization of the SI. This SI focuses on some of the latest research outcomes and review articles in the field of ceramic AM in China, representing the frontier progress of ceramic AM research in China. Due to the limitations of time and space, some excellent work cannot be included in this SI in a timely manner. We hope that the SI can provide a useful reference for promoting the research and application development of ceramic AM in China. With ceramics as inks and focused energies as pens, would ceramic AM mark the new chapter like ‘Ma Liang the Magic Brush’, manifesting a significant leap from the processing and engineering research of ‘Accumulating sands to form a pagoda’ to the popularized application of high added value of ‘Turning stones into gold by touching’? We believe that with the unremitting efforts and progress made by researchers worldwide, this dream will eventually come true in the near future!

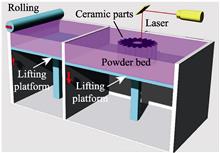

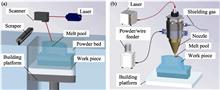

Ceramics, with its excellent thermal, physical and chemical properties, have great potential applications in various fields, such as aerospace, energy, environmental protection and bio-medicine. With the development of relevant technology in these fields, the structural design of core components is increasingly complex, and the internal microstructures gradually become customized and gradient. However, the hard and brittle features of ceramics make it difficult to realize the forming of special-shaped parts by traditional manufacturing methods, which in turn limits further application. As a rapidly developing additive manufacturing technology, laser additive manufacturing technology presents a momentous advantage in the manufacturing process of extremely precision ceramic components: free molding without mold and support, quick response feature and short developing cycle, etc. At the same time, the technology can realize the flexible deployment of ceramic parts, which is expected to solve the problems mentioned above. Three kinds of powder-based laser additive manufacturing techniques of ceramic were reviewed in this paper: selective laser sintering and selective laser melting based on powder bed fusion technology; laser engineered net shaping based on direct energy deposition technology. The forming principle and characteristics were mainly discussed; the research progress of ceramic green body densification process in selective laser sintering technology and the forming principle, propagation mechanism and control methods of ceramic green body cracks in selective laser melting, and laser engineered net shaping technology were reviewed; the technical characteristics of selective laser sintering, selective laser melting and laser engineered net shaping technologies in shaping of ceramic parts were compared and analyzed; and the future development trends of laser additive manufacturing technology of ceramic parts were prospected.

Melt-grown oxide eutectic ceramics possess a large area of clean and firmly bonded phase interfaces through liquid-solid phase transformation, which makes them present excellent high-temperature properties such as strength retention, creep resistance, thermal stability, oxidation and corrosion resistance. As a result, directionally solidified oxide eutectic composite ceramics have been regarded as one of candidates for new generation of high temperature structural materials which can service above 1400 ℃ in oxidation environment for a long period. In recent years, laser additive manufacturing based on melt growth has developed into the most promising technique for preparing ultrahigh-temperature oxide eutectic ceramics due to its unique advantage in one-step fabricating highly dense parts with large sample size and complex shape. In this paper, laser additive manufacturing technology was summarized in terms of forming principle, technical features and classification. The research status and the encountered technical problems in additively manufacturing melt-grown oxide eutectic ceramics were reviewed. Moreover, the research progress on laser additive manufacturing oxide eutectic ceramics was introduced from the aspects of laser forming process, solidification defect control, solidification microstructure evolution, and mechanical properties. Finally, the key bottlenecks of realizing engineering applications of the laser 3D-printed oxide eutectic ceramics were pointed out, and the future development directions of this field were prospected. The focus of the future work can be summarized into four points: developing high-quality spherical eutectic ceramic powders, preparing large-scale eutectic parts with complex shapes, accurate controlling solidification defects, as well as strengthening and toughening eutectic composites.

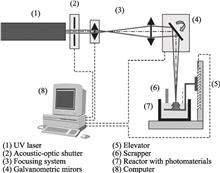

At present, stereolithography 3D printing technology is widely used in ceramic additive manufacturing because of its high printing accuracy. Among them, the stereolithography ceramic slurry of non-oxide ceramics such as silicon carbide, silicon nitride, etc., has problems such as poor dispersion stability and low curing layer thickness because the incident light is difficult to penetrate and produce light curing reaction for printing high-solid-loading slurry. This is all because the refractive index and optical absorbance of the non-oxide ceramic printing material powder are relatively high. Therefore, printing and molding of high-solid-content non-oxide ceramics have become main challenges in stereolithography 3D printing, and the technology has attracted a large number of researchers to study its light-curing mechanism, powder control and other mechanisms. This paper systematically summarizes the research works of several non-oxide ceramics such as light-curing slurry preparation, light-curing molding, organic matter removal, and sintering densification. It also analyzes and discusses several methods of adjusting composition of photosensitive resin and modifying ceramic powder, and proposes innovative solutions to improve the slurry performance of non-oxide ceramics, optimize its light-curing printing, repair its densification defects and improve its performance. And the ultimate goal is to promote the advancement of high-precision preparation technology for light-curing additive manufacturing of large-size, complex-structure non-oxide ceramic parts.

As an important functional material, piezoelectric ceramics not only have the characteristics of high strength, high hardness, corrosion resistance, etc., but also can realize the mutual conversion between mechanical energy and electrical energy. Piezoelectric ceramics are widely used in sensors, drivers, capacitors and other piezoelectric parts, playing an important role in high-end equipment such as marine exploration, biomedicine, and electronic communications. The development requirements of intelligent, integrated, and lightweight piezoelectric functional devices in advanced technology fields have pushed their shape more and more complex. However, traditional fabricating processes, such as slip casting, injection molding, mould pressing, and machining, depend on molds or grinding tools. It is difficult to design and fabricate complex shape piezoelectric ceramics, especially with hollows and overhangs. Additive manufacturing technology can rapidly fabricate any complex structure parts based on the layer-by-layer fabricating principle with advantages of high molding efficiency and without molds. It can meet the needs of individualized, integration and complex manufacturing. In recent years, it has received extensive attention from researchers in the field of piezoelectric ceramics in both domestic and abroad. This article summarizes the main types of current additive manufacturing piezoelectric ceramics and their development status from the perspective of three raw material forms: powder, slurry and bulk materials, then comprehensively compares the characteristics of various processes. Application of additive manufacturing of piezoelectric ceramics in different fields has also been introduced. Finally, the challenges faced by additive manufacturing piezoelectric ceramics and the possible future development trends are summarized and prospected.

Because of low thermal conductivity and weak physical and chemical stabilities, traditional “phosphor in silicone” color converters are precluded from high-power white LED applications. All-inorganic bulk luminescence materials not only can circumvent organic encapsulation, but also have higher thermal conductivity. However, those bulk materials are high in cost and very difficult to be shaped into three-dimensional structures. Here, based on amorphous silica nanoparticles, a slurry, containing (Gd,Y)AG:Ce phosphor powders and can be polymerized under UV light, were developed. Bulk (Gd,Y)AG:Ce-silica glass composites were prepared successfully through photo curing, debinding in air and pressureless sintering. Under excitation of blue light, these luminescence glass-ceramics exhibit broadband orange emission peaking at 575 nm with internal quantum efficiency higher than 90%. Our results show that the interfacial reaction between (Gd,Y)AG:Ce and silica glass is very weak, and thus the former can be well embedded into bulk silica glass. Such all-inorganic color converters were further used to fabricate high-power warm white LEDs with correlated color temperature smaller than 4500 K, color rendering index higher than 75, and luminous efficiency of 74 lm·W -1. Luminescence saturation threshold of the as-fabricated laser lighting device is as high as 2.84 W·mm-2, where its luminous flux can achieve 180 lm. Moreover, preparation of (Gd,Y)AG: Ce-silica glass composites is compatible to 3D printing technology, thus allowing the mass manufacturing of color converters with complex 3D structures, which may promote personalization and modularization of high-power white LEDs.

In order to prepare activated alumina catalyst carrier with efficient chemical catalytic reaction and complex fine structure, we prepared a low viscosity, high uniformity and high solid content stereolithographic slurry. Effects of resin ratio and coupling agent modification on the particle size distribution of activated alumina and the stability, uniformity and rheological properties of slurry were studied by particle size analysis and rheological test. When w(HEA) : w(HDDA) : w(TMPTA) : w(modified-EA)=1.5 : 1.0 : 2.5 : 5.0, the viscosity of premix at shear rate 1 s -1 is only 0.35 Pa·s. After powder modification, KH560 polymer chain attached to surface of activated alumina, changing the activated alumina from hydrophilic to hydrophobic, which improved the uniformity and stability of slurry, caused steric hydration between powders and reduced powder agglomeration, leading the average diameter of activated alumina being decreased from 4.43 μm to 3.89 μm. Slurry with solid content of 52% (in mass) was prepared by wetting mixing method and then successfully printed. Debounded and sintered activated alumina samples maintains a complex irregular thin-walled structure, and their porosity and density are 51.3% and 1.93 g/cm3, respectively.

Due to good mechanical properties, biocompatibility and corrosion resistance, zirconia ceramic has been widely used in dental repairing. However, the present technologies for zirconia ceramic fabrication based on stereolithography have some drawbacks, such as low fabrication accuracy, low debinding efficiency, high shrinkage, and shrinkage anisotropy. In order to solve these problems, a kind of hybrid resin was prepared by using different monomers with different functionalities, and then zirconia ceramic slurry with solid content of 55% (volume percentage) was prepared by using this hybrid resin, which dispersed organic matter pyrolysis interva, promoting debinding efficiency and avoiding crack. Besides, effect of laser power and scanning speed to the curing unit shape were studied, the optimum laser power of 670 mW and scanning speed of 2500 mm/s were selected to meet requirments of fabrication accuracy and efficiency. In addition, effects of scanning line space and scanning line width compensation to horizontal dimension accuracy and slicing thickness to the stacking dimension accuracy were studied. Optimum process scanning line space of 0.08 mm, scanning line width compensation of 0.10 mm, and slicing thickness of 0.03 mm were determined. Meanwhile, the green part was debinded in nitrogen atmosphere, which reduced pyrolysis rate of organic matter, performed a further improvement of debinding efficiency and green part cracking. At last, the debinded part was sintered. The plane and stacking direction shrinkages of the sintered part are (18.26±0.10)% and (19.20±0.13)%, respectively. All these results demonstrated that the shrinkage is reduced and the shrinkage anisotropy is reduced obviously, which provides basis for application in dental repairing.

With the continuous development of science and technology, Si3N4 ceramics are playing an increasingly important role in high-tech fields such as aviation machinery, biology and medical treatment. In this work, Si3N4 ceramics were successfully prepared by digital light processing (DLP) technology using Si3N4 powder coated with Al2O3-Y2O3 as raw material. Effects of solid loading of slurry on the performance of Si3N4 ceramic slurry, Si3N4 ceramic green parts and Si3N4 ceramics were systematically studied. The results showed that when the solid loading of slurry was less than 40.0% (in volume), its viscosity was less than 2 Pa·s at shear rate of 30 s-1, which can be used for DLP forming. In that case, the single curing depth of the slurry decreased with the increase of solid loading of the slurry, while the relative density and flexural strength of Si3N4 ceramics formed by DLP increased firstly and then decreased. The relative density and flexural strength reached the maximum of 89.8% and 162.5 MPa at solid loading of 37.5% (in volume), which were 10% and 16% higher than those with solid loading of 32.5% (in volume), respectively. In this work, the properties of Si3N4 ceramics formed by DLP were optimized by determining the best solid loading, which laid the experimental foundation for the photocuring of non-oxide ceramics such as Si3N4.

Photopolymerization 3D printing method is an effective means for the manufacturing of ceramics with highly complex-shaped structures and exceptional performance. The printed samples need to undergo heat treatment such as debinding and sintering before becoming usable final ceramic parts in various industrial applications, and the debinding process has a great impact on the properties of the printed ceramic parts. In this study, effect of the debinding process on physical properties and mechanical performance of the cordierite ceramics prepared by DLP photopolymerization 3D printing was studied, and defect suppression strategy was established accordingly. The effects of debinding atmosphere and heating rate on surface cracks and material elemental distribution of ceramic samples were compared and analyzed. The microstructure, size shrinkage, relative density, and mechanical performance such as bending strength of the sintered samples were also studied. It is found that the debinding atmosphere has the most significant influence on the properties of the sintered samples, in which the surface cracks can be significantly reduced, and the relative density, and bending strength can be increased when the debinding process is conducted in argon atmosphere at the optimized heating rate of 1 ℃/min. After debinding and sintering, the cordierite ceramic samples with a relative density of (94.6±0.3)% and a bending strength of (94.3±3.2) MPa was obtained. In conclusion, this study provides a scientific basis and technical reference for fabrication and application of cordierite ceramics based on photopolymerization 3D printing method.

Single crystal superalloy hollow blade is an important part of aero-engine, and its inner cavity structure is prepared by ceramic core. With the increase of thrust-weight ratio of aero-engine, the core structure is more and more complex. Traditional preparation technology is difficult to meet the requirements of complex core preparation. Stereolithography 3D printing of ceramic cores provides a feasible scheme for the preparation of complex cores. In order to improve the surface roughness of stereolithography 3D printed ceramic cores caused by step effect, this study used silicon-based core paste with solid content of 63% (in volume), and the cores of the green bodies were sintered at 1100 ℃ to 1300 ℃. Microstructure, element distribution, phase composition, surface morphology, and roughness of the silicon-based ceramic core were analyzed. It is found that printed surface of the core is smooth without obvious surface defects. Roughness of the printed surfaces of the sintered cores at 1100, 1200 and 1300 ℃ are 1.83, 1.24 and 1.44 μm, respectively. Their surface of lamellar stacking direction has lamellar structure characteristics, and microcracks appear between lamellar, and surface roughness of core sintered above 1200 ℃ meets the requirements (Ra≤2.0 μm) of hollow blade. Sintering temperatures affect the liquid content, mullite production, mullite formation morphology, and glass phase distribution of cores during the sintering process, and the surface roughness of stereolithography 3D-printed silicon ceramic cores is positively affected. Stereolithography 3D printing ceramic core technology combined with sintering process can produce a silicon-based ceramic core which surface roughness meets the requirements of an advanced hollow blade.

Debinding heat treatment process play an important role in forming quality of 3D printing ceramics. At present, the alumina green body prepared by light curing 3D printing is sintered after debinding in air. The final alumina ceramics may have defects such as micro cracks, resulting in poor mechanical properties. Direct heating and debinding in air may lead to cracks caused by reaction between resin and oxygen in green body. To avoid this situation, this work studies the printing heat treatment process of alumina ceramics based on digital light processing (DLP) technology. The alumina ceramic green body prepared by 3D printing was degreased either in air or in argon, and their macro morphologies were compared with each other. It is found that there are micro cracks in the alumina green body debinding in air. After being sintered in air, the alumina ceramics was obtained and their micro morphology and macro properties were characterized. Average grain size of alumina ceramics debinding in argon was larger than that directly debinding in air, while the grain structure was dense without obvious pore and impurity. Moreover, in terms of mechanical properties, alumina ceramics debinding in air have higher compressive strength. The highest density of alumina debinding in argon reaches 96.72%, and the compressive strength reaches 761.7 MPa, significantly improved as compared with the one debinding in air.

Gypsum is a common material for statues, building, and casting molds (alloys and ceramics). Due to the incomplete hydration reaction between water and gypsum, it is difficult to print high-strength gypsum products using 3D printing techniques such as Binder Jetting. To enhance its strength, the hydration reaction should be completely performed, which could be fulfilled by direct ink writing (DIW). However, the reaction in the gypsum paste for DIW is so fast that less time is left for operating a 3D printer. In this work, a printable gypsum paste with a reasonable setting time was developed to print 3D gypsum structures via direct ink writing. A retarder and a thickener were introduced into the paste to prolong its setting time for operating and tailor its rheological property for printing, respectively. The setting time, expansion and rheological properties of the pastes were tested by the Vicat apparatus, consistometer and rheometer, respectively. The results show that citric acid (CA) is a suitable retarder, although decreases its compressive strength due to the directional grown gypsum crystals resulting from the selective adsorption of CA on gypsum powder, while hydroxypropyl methylcellulose (HPMC) is an acceptable thickener, which affects forming flocculation structure in the paste, resulting in higher viscosity and shear modulus. Optimal amounts of CA and HPMC for the printable gypsum paste are 0.6% and 0.3% (in mass), respectively. Three-dimensional gypsum structures such as spider web and scaffold are successfully printed via direct ink writing, which compressive strength is around 20 MPa, much higher than that printed via Binder Jetting.

Belonging to the family of SiC-based composites, Al/SiC has excellent mechanical and thermal properties, making it irreplaceable in high-power electronic devices, key cooling components of 5G base station, electric vehicles, high-speed brake pads, space probe operation devices, and other related fields featured by high technologies. The melt infiltration method, which can achieve near-net forming, has been recognized to be a favorable method for preparing Al/SiC composites to overcome the disadvantages of traditional processing. How to obtain a high-quality silicon carbide (SiC) ceramic green body is a key for the perfect melt infiltration method. Selective laser sintering (SLS) technology provides a new opportunity for a top grade ceramic forming process, which is rapid and efficient in realizing large-scale and complicated-shape without cast molding. Here, the SiC green body was obtained by SLS technique with thermoplastic phenolic resin as binder and its content lower than 15% (in volume) for the subsequent procedure to fabricate composite materials. However, low binder content results in low flexural strength. As the resin content increases to 25% (in volume), the strength of the SiC green body reaches 3.77 MPa with a strength increment of 702.1% for the SLS SiC green body. Spray drying was applied to form more spherical powder. Nevertheless, the porosity of the SiC green body is still high (71.18%), due to porous microstructure remaining in spray-dried powder, which leads to deteriorated strength of the green body.

For ceramic stereolithographic (SL) additive manufacturing, the solid loading of ceramic photosensitive slurry plays an important role during the SL process. In this study, Al2O3 ceramics were fabricated by SL additive manufacturing from photosensitive Al2O3 slurries with various solid loadings, and the solid loading-property relationships of Al2O3 ceramic were performed. The effects of solid loading on not only the rheological behavior and curing property of the photosensitive Al2O3 slurry but also the microstructure and mechanical properties of the Al2O3 ceramic were investigated. The results showed that both the viscosity and shear stress increased with the increase of the solid loading. High viscosity was greater than the critical value for self-leveling during the SL process. The curing properties of photosensitive Al2O3 slurries were highly depended on the sold loading. Moreover, clear effects on the defect characteristics of Al2O3 ceramics manufactured from various photosensitive slurries were observed. These manufactured defects are critical for the mechanical behavior of Al2O3 ceramic. In addition, the relationship between rheological behavior and curing property of photosensitive Al2O3 slurry. Meanwhile, the resulting microstructure and mechanical properties of the Al2O3 ceramic were also illustrated. Inhomogeneous structure caused by high viscosity can lead to a sintered ceramic with poor strength. These findings provide fundamental understanding for SL additive manufacturing of ceramics.