View fulltext

View fulltext

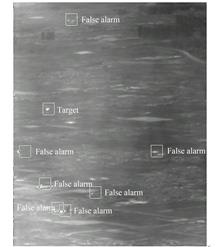

When an infrared photoelectric detection system detects a target in a complex airborne scene, the spatial distribution of the ground false alarm interference source is consistent with the spatial distribution of the small dim target. Therefore, a multi-dimensional feature association detection algorithm based on moving target features was proposed herein. First, feature points were detected in complex scenes, and a frame skipping mechanism based on the relative velocity-height ratio was introduced. Candidate targets were detected by inter-frame image difference after image registration. Simultaneously, multi-dimension and multi-frame correlations based on the kernel correlation filter were used to suppress false alarms. In an airborne environment where the vehicle speed-to-height ratio is greater than 30 mrad/s and frame time is less than 10 ms, the average detection rate of this algorithm is 99.13%, and the false alarm rate is 10-5. This method was verified in various complex scenarios. In addition, it is suitable for pipeline parallel operation and meets the engineering needs.

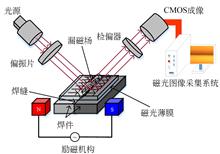

Nondestructive testing of the surface and subsurface of welding defects is key for ensuring the quality of welding products. A three-dimensional (3D) reconstruction method of welding defects based on Faraday magneto-optical imaging (MOI) is investigated to realize the shape and size recognition of welding defects. First, based on the principle of MOI, the corresponding relationship between the magnetic induction intensities of the magnetic leakage field and MOI is analyzed. Subsequently, using a pulsed laser welding pit (3 mm × 0.3 mm × 0.25 mm) as the research object, a 3D finite element magnetic field simulation model of the pit is established to investigate the distribution of magnetic induction intensity of the leakage field. Moreover, a two-dimensional plane contour of welding pit defects is extracted via image digitization and the pixel value distribution of MOI. A gradient-deviation algorithm is designed to construct the depth information. Finally, the 3D profile of the welding defect is obtained. Results show that the magnetic field intensity should be greater the farther it is from the center point of the welding pit defects. Meanwhile, the closer it is to the center point of the Y-axis direction, the larger is the gradient of the field intensity change. The maximum depth of the pits is between 150 and 200 μm, and the differences in the average and median depths are 0.1 and 2 μm, respectively, which are different from those of a confocal microscope. MOI technology affords high identification accuracy and can realize the 3D contour reconstruction of welding defects.

A convolutional neural network (CNN) model for machine vision inspection and identification can identify and measure the components, size, and other features of an object under test. Herein, a fine-tuning transfer learning technique for semantic segmentation based on a label-reserved softmax algorithm was proposed. First, the transfer learning modeling of semantic segmentation for machine vision inspection and identification was performed. Transferring more CNN model weights would reduce the initial loss of the model. Second, a fine-tuning transfer learning method based on label-reserved softmax algorithms was proposed, which could realize fine-tuning transfer learning with all model weights of slightly different detected objects. Experiments based on custom-developed datasets show that the training time for training models to satisfy the requirements of machine vision inspection and identification is reduced from 42.8 min to 30.1 min. Application experiments show that this transfer learning technique enables semi-supervised learning for the inspection of standard component installation, the inspection of missed and mis-installation cases, and the identification of assembly quality. The training time for the transfer learning of new chassis is less than 20.2 min, and the inspection accuracy reaches 100%. The fine-tuning transfer learning technique is effective and satisfies the requirements of machine vision inspection and identification.

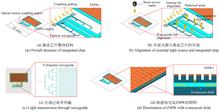

To reduce the cost and size of zero-mode waveguide lighting systems, the on-chip integration of diffraction gratings, optical waveguides, and zero-mode waveguides was designed and completed, and the micro-nanostructure and performance of the integrated chip were verified. The FDTD method was used to simulate and design the integrated chip. The on-chip diffraction grating, optical waveguide, and zero-mode waveguide array were fabricated by micro-nano machining methods, and the micro-nanostructure was characterized. A fluorescent microsphere test was performed to verify the performance of the chip. The test shows that the prepared integrated chip can realize the effective excitation of the fluorescent microsphere. The micro-nanostructure characterization shows that the diffraction grating period, tooth width, and etching depth are (352.8±2.6) nm, (155.3±2.4) nm, and (67.8±3.5) nm, respectively. The width and height of the waveguide core layer are (504.05±10.35) nm and (184.9±8.9) nm, respectively. The diameter and depth of the zero-mode waveguide are (200.2±6.4) nm and (301.3±7.6) nm, respectively, which meet the design requirements. The 22 mm× 22 mm chip, with a minimum linewidth of 155 nm, provides a compact and efficient solution for zero-mode waveguide illumination through the on-chip integration of eight diffraction gratings, approximately 1 000 optical waveguides, and hundreds of thousands of zero-mode waveguide array structures.

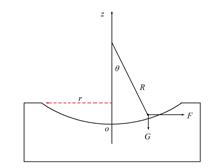

In lithography, the uniformity of resist coating considerably affects the consistency of line width after spin-coating. To obtain homogeneity of the resist-layer thickness on the upper surface of a curved substrate, a hydrodynamic model of a non-Newtonian fluid element is first established on the surface of the curved substrate under spin-coating. According to the corresponding boundary conditions and constitutive equation and continuity equation of the non-Newtonian fluid, the relationship between the nature of the fluid, curvature radius of the surface, horizontal vector radius, rotation speed and time, and the final thickness of the fluid is deduced and obtained. Second, a rheometer is used to calibrate the fluid viscosity of 950 K PMMA C 2% resist. A spin-coating experiment is conducted on a curved substrate using rotational velocity as a single variable. After centrifugation, the thickness was measured by ellipsometry. The relationship between the resist-layer thickness and the change in the vector radius is obtained and demonstrated with theoretical results. Experimental results show that when the spin speed is 2 000 r/min, the theoretical thickness is 267 nm, measured thickness is 230 nm, and deviation ratio is 13.86%. When the spin speed is 3 000 r/min, the theoretical thickness is 178 nm, measured thickness is 172 nm, and deviation ratio is 3.37%. After spin-coating, the soft-bake will further reduce the thickness of the resist-layer,and the deviation is within the normal range. Therefore, the mathematical model can provide a theoretical guidance for homogeneity after spin-coating, and the established model has a good predictability.

An innovative design for a fast tool servo (FTS) system exhibiting high response frequency, high precision, and a high driving force was proposed herein. A flexible hinge fitted with a generalized conic line was applied to construct a novel flexible mechanism. The coupling error of the undesired movement direction of the flexible tool holder was decreased efficiently using a symmetrically arranged structure. Moreover, the kinematic characteristics of the mechanism were comprehensively modeled. Subsequently, based on an improved BP neural network, a multi-objective optimization design for the structural size of the flexible mechanism was performed. The stroke and natural frequency of the designed structure was analyzed to balance these two conflicting design objectives. The three-dimensional model of this device was established based on structural parameters obtained via optimization. Furthermore, a finite element analysis was performed. It is demonstrated that the algorithm affords a perfect optimization effect. The flexible mechanism designed via optimization could achieve advanced performances and was hence suitable for the FTS flexible mechanism. Finally, a prototype of the device was manufactured, and performance tests were conducted to verify the optimization design process. Experimental results show that the static and dynamic performances of the proposed device satisfy the design requirements. Its natural frequency exceeds 7.6 kHz, the nominal stroke is approximately 6.4 μm, the resolution is approximately 12 nm, and the following accuracy is approximately 0.3 μm. In addition, the experimental results verify the feasibility of the designed FTS system for ultraprecision machining.

To improve the cutting depth of chemical vapor deposition (CVD) diamond, the effects of laser power, focus position, repetitive frequency, scanning speed, and transverse mode on the width of cutting seam, cutting depth, and roughness of CVD diamond was used to achieve a novel high repetition rate laser with acousto-optic modulation. The results show that the cutting depth and width of upper kerf increased with the increase in laser power; the maximum cutting depth was obtained when the focus was moved down along with cutting depth; the cutting depth decreased and the width of upper kerf increased with an increase in repetition frequency; with the increase in cutting speed, the surface roughness decreased slowly and increased significantly subsequently; the width of upper kerf increased with the increase in the number of laser modes. The best result is obtained with a unidirectional cutting depth of 7.2 mm, surface roughness of 0.804 μm, and kerf’s width of 350 μm, while the laser power is 12 W, repetition frequency is 6 kHz, cutting speed is 1 500 mm/min, and the focus position is located on the concave surface. Hence, a large cutting depth of CVD diamond with low surface roughness is achieved.

To obtain and make full use of the multi-spectrum information of the scene, and to lay the foundation for the research of multi-band image algorithms, a four-band coaxial imaging experimental platform of visible light + near infrared, short wave infrared, mid-wave infrared and long-wave infrared was developed based on uncooled infrared focal plane array (IRFPA). Image processing cases based on the four-band imaging experimental platform were presented. FPGA was used in the preprocessing of each channel of image and the fusion of multi-band image. The image quality of each band was optimized by the preprocessing procedure, that included the blind point correction of the visible sensor and nonuniformity correction of the mid-wave and long-wave infrared sensors based on grad-filtering. Dual-band and four-band image fusion enhanced the color of the fusion image obtained by linear combination in the YUV color space by color transfer, thus resulting in a natural color fusion image as well as ensuring the operating efficiency of the algorithm. Dual-band infrared temperature measurement was performed using medium and long-wave infrared. The blackbody experiment shows that in the temperature range of 20-80 ℃, the accuracy of dual-band temperature measurement is significantly higher than that of single-band temperature measurement, the error of dual-band temperature measurement is less than 3.5%, and the single-point temperature fluctuation range is less than 0.7%. The outfield experiment results show that information fusion images can effectively enhance the human eye’s understanding of scene information. The four-band imaging experimental platform can easily obtain the four-band information of the scene, and image fusion and dual-band temperature measurement can strengthen the understanding of scene information.

Maskless lithography based on spatial light modulators is an important development direction of lithography technology. In recent years, with the improvement in digital micromirror device (DMD) chip integration and performance, maskless lithography based on DMD has become the main digital lithography technology. By virtue of a programmable digital mask that can be gray-scale modulated to replace the prefabricated physical photomask used in traditional lithography, it can greatly simplify the process of lithography and improve the flexibility of lithography. It is widely used in many research fields including planar micro-nano devices, metamaterials, microfluidic device chips, and tissue biology. Starting from the principle of maskless lithography, we briefly introduce the structure of uniform illumination system and miniature projection system, and then summarize the development of spatial resolution enhancement technology for traditional planar lithography, grayscale lithography, and three-dimensional micro-stereolithography technology. Finally, we highlight the typical applications of digital maskless lithography and propose its future development direction.

The polarization axis direction of the sub focal plane polarization image sensor influences the accuracy of the polarization parameter calculation using the Stokes vector. Therefore, it is necessary to calibrate the sensor before using it. To meet this requirement, a method based on measuring the phase difference of the curve fitted by the average output value of pixels in each polarization axis direction of the sub focal plane polarization image sensor is proposed, and the simulation and actual test are conducted. First, the linearly polarized light vertically irradiating the sensor surface is rotated for several cycles according to a certain step size, and the sensor takes pictures simultaneously. Then, the region of interest of the image is selected, and the pixel values in the same polarization axis direction in the region are averaged to obtain the sequence of the average values of the pixels in each polarization axis direction changing with the rotation angle. The Fourier series fitting method is used to fit each sequence, and the expression of the pixel output value changing with the rotation angle is obtained. Finally, one polarization axis is selected as the reference direction, and the other polarization axis is the phase difference between the expression of this direction and that of the reference direction. The actual test results show that the calibration error is less than 0.1°. This method has high calibration accuracy and good operability. Furthermore, it can complete the task of calibrating the polarization axis direction of the sub focal plane polarization image sensor.

A three-directional laser beam splitting system with high precision pointing adjustment iwas developed, including its hardware and software. This laser beam pointing control of sodium fluorescent Doppler lidar facilitated obtaining quick and accurate signals for long distance observation. Based on the design requirements of the optical system, the physical and mechanical characteristics of the beam splitter and reflector were presented. An angular stroke of 1.18° can be achieved using six high-precision stepper motors combined with six high-precision optical 2-D adjusting frames, with an adjustment precision of 1.1', and the success rate of repeated positioning is 99.3%. The experimental results meet the precision requirements of the high energy laser emitting system. According to the performance requirements of the system, the laser energy loss is 11.6% after the beam splitter, which meets the laser energy emission requirements of sodium fluorescent Doppler lidar. A set of control software for the system was written to support remote automatic control of the laser lidar.

To solve the problems of poor centroid recognition and low processing efficiency in 3D reconstruction of parallel chromatic confocal measurement systems, a high efficiency and high precision 3D reconstruction method was proposed in this paper. In this algorithm, target extraction and image splicing were performed on all the experimental images to obtain spliced images. In addition, using the regionprops function in MATLAB, the centroid and its connected area of each measured point were extracted, and the H-value and height relationship was constructed with the color conversion algorithm method. Finally, the interpolation fitting algorithm was used to reconstruct the 3D surface topography of the object. To verify the feasibility of the algorithm, the letter “N” and “E” on a one-yuan coin was measured in the author’s self-built parallel chromatic confocal system. The experimental results show that the axial measuring range of the system is 80 μm. Therefore, the measurement accuracy can reach the micron level, and this algorithm can quickly and effectively reconstruct the 3D surface topography of the sample. Compared with the conventional method, the processing efficiency is 5-6 times higher.

In order to address the limitation of poor reliability of temperature-sensitive coefficient calibration of grating in an ultra-low temperature environment, a reference thermometer probe and fiber Bragg grating sensor were encapsulated in a self-designed non-contact liquid-nitrogen-cooled temperature measuring mold, and calibration experiments were conducted at ultra-low temperatures ranging from 93 K to 293 K. The thermal sensitivity coefficient of the bare grating and thermal expansion coefficient of the coating were used to verify the credibility of the experimental design. The experimental results indicate that the maximum initial temperature change rate of the reference thermometer is 1.8 K/min, which effectively reduces the temperature change rate of the temperature measuring mold and improves the temperature consistency between the reference thermometer and labeled grating. The test results are in good agreement with those of comparable studies. The temperature sensitivity of the bare grating decreases from 9.18 pm/K@293 K to 2.19 pm/K@93 K due to its low temperature nonlinearity. The thermal expansion coefficient of organic modified ceramic (ORMOCER) is 3.7×10-6 K-1 at room temperature. The temperature-sensitivity coefficient of one layer of the ORMOCER coating with a thickness of 50 μm is 4.43 pm/K. At 93 K, the temperature-sensitive coefficient is 7.17 pm/K, the temperature-sensitivity coefficient and linearity of the coating grating are significantly improved.