ConclusionsHerein, AlSi10Mg alloy samples were successfully fabricated along different building directions using LPBF. After static mechanical tests, the room-temperature compressive strength could reach 201.0 MPa and the yield strength was 251.3 MPa. The tensile and yield strengths at 175 ℃ could reach 195.0 and 160.0 MPa, respectively. The static mechanical tests of the samples along different building directions revealed that the horizontal samples showed with better compression properties at room temperature and better tensile properties at a high temperature than the vertical samples. The LPBF-processed AlSi10Mg vertical sample showed excellent 107-cycle median fatigue strength of 151.25 MPa, while relevant research shows that the high cycle fatigue strength of AlSi12 alloys processed using LAM is 88.7 MPa. The excellent high-cycle fatigue resistance of AlSi10Mg processed using LAM was attributed to its unique fine cellular grains and fine Al-Si eutectic phases at grain boundaries. The fatigue life and threshold of fatigue crack growth of the LPBF-processed AlSi10Mg alloy were ~2.1×105 cycles and 0.981 MPa·m1/2, respectively. The findings of this study show that the excellent mechanical properties of AlSi10Mg alloys can be obtained by LPBF processing. This study can provide an academic reference for the application of LAM-processed aluminum alloys in aerospace and other fields.

ConclusionsIn this study, CoCrFeMnNiTix HEA coatings with different Ti content were successfully prepared on the surface of 45 steel using laser cladding technology. The microstructure and properties of the coatings were also investigated. The results show that the CoCrFeMnNiTix HEA coatings consist of FCC solid solution and TiC particle phases. It also shows that the lattice constant first increases and then decreases as the content of the Ti element increases. The microhardness of CoCrFeMnNiTix HEA coatings increases as the content of the Ti element increase. The addition of the Ti element leads to the solution strengthening and second phase strengthening of the coatings. The corrosion mechanism of CoCrFeMnNiTix HEA coatings evolves from pitting to intergranular corrosion. In the anodic polarization stage, the segregation of the Ti element intensifies intergranular corrosion. The wear mechanism of CoCrFeMnNiTix HEA coatings changes from adhesion wear to oxidation wear and abrasive wear due to the increase in the hardness and averaged temperature during friction. The change in wear mechanism minimizes the friction coefficient of CoCrFeNiMnTi1.00 coating. The oxidized adhesive layer has a certain protective effect on the surface of the coating. The CoCrFeNiMnTi0.25coating has the best corrosion and wear resistances.

ConclusionsThis study combines double-sided laser and laser swing welding technologies to realize a double-sided laser swing welding of 2195-T87 aluminum-lithium alloy T-joint. Double-sided laser swing welding with circular swing method is used to obtain 2195-T87 aluminum-lithium alloy T-joint with firm surface forming and low porosity. The porosity rate is reduced from 1.89% to 0.52%. Compared with conventional double-sided laser welding, double-sided laser swing welding can significantly refine the equiaxed crystal area in the middle of the weld by beam swinging and stirring the molten pool, and significantly reduce the size of the equiaxed, fine-crystal area to enhance the joint’s load-bearing capacity. The average diameter of the equiaxed crystal in the middle is reduced from 21 to 13 μm, while the average diameter of the equiaxed, fine-crystal region is reduced from 44 to 23 μm. The obtained joints have maximum axial and transverse tensile strengths of 267 and 420 MPa, respectively. Compared with nonswing welding, they increased by 123 and 95 MPa, respectively, reaching 45% and 70% of the base metal strength. Our study shows that double-sided laser swing welding can design 2195-T87 aluminum-lithium alloy joints of better surface forming, lower porosity, and greater strength.

ConclusionsThe joint’s weld cross-section had a typical "hourglass shape" . Typical columnar crystals appeared in the middle and lower welds, with a few equiaxed crystal zones at the top of weld. The grain in the weld zone coarsened noticeably when compared to that in the base metal and heat-affected zone. Near the weld zone of the upper fusion line, needle-like crystals in a plane form existed, which formed elongated columnar dendritic crystals through competition and elimination mechanism. Near the weld zone of the middle fusion line, the transition from cellular crystals and cellular-like dendrites to columnar dendrites happened. There were migrating grain boundaries in the heat-affected zone. Moreover, two modes, including epitaxial and nonepitaxial growths, emerged near the fusion line of the weld seam. The grains in the middle of weld grew in a typical discontinuous pattern, with the grain increasing from fine to coarse. However, these grains were quickly replaced by new grains. The grain growth direction was consistent at the top of the weld, indicating aggregative characteristics. The continuous growth of the columnar crystals resulted in a large perforated grain.

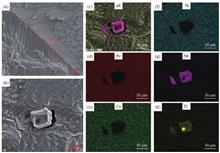

ConclusionsNanosecond pulse laser with different parameters was used to conduct laser cleaning experiments. Macroscopic and microscopic morphologies of the surfaces after laser cleaning were analyzed, and their properties were studied. The following conclusions were obtained. Macroscopic analysis of workpiece surface cleaning state shows that when the paint layer is insufficient or excessive cleaning, the cleaning degree can be roughly judged according to the change of surface color. The microstructure analysis of the workpiece surface cleaning state shows no burning trace on the paint surface when the workpiece surface cleaning is insufficient, and the surface elements are mainly C, O, and Si. Meanwhile, when the workpiece surface cleaning is moderate, the surface has visible microscopic oxide film cracks, and the surface elements are mainly Fe and O. Furthermore, the surface has an evident remelting phenomenon when the workpiece surface is overcleaned, and the surface elements are mainly Fe and O. The binarization processing results show that with an increase in cleaning degree, the number of white pixels in the image decreases, whereas the number of black pixels increases. Moreover, when the number of black and white pixels is almost the same, the cleaning is complete. According to this method, the surface quality after laser cleaning can be accurately evaluated. Our study provides an effective cleaning method and testing means for the surface paint film of the bogie wheel of high-speed rail.

ConclusionsIn this paper, a finite element model was developed to simulate the transient temperature field and the molten pool evolution for the selective electron beam melting(SEBM) additive manufacturing process of metals, which was examined against the analytical solution. With increase of the scanning speed, or increase of the beam radius, or decrease of the beam power, the maximum temperature decreases, and the length, width and the depth of the molten pool all decrease. The temperature field and the shape of the molten pool are not symmetrical about the center line of the scanning path, namely, on the side near the scanned zone, the heat affected range is greater, the temperature gradient and the molten pool size are smaller. From the cross section of the molten pool obtained by simulation, we can predict the overlapping rates of multi-bead and the fusion state of multi-layer under certain process parameters.

ConclusionsIn this work, 316L-IN625 gradient material with the gradient change in the material composition was prepared by LD. The results show that with the reduction of 316L composition, the microstructures of different regions of the gradient material displayed cellular dendrites, columnar grains, coarse dendrites, and nearly equiaxed grains in sequence. Compared with the joint sample, the 0.2% yield strength of the 316L-IN625 gradient sample increased to 289 MPa. However, the tensile strength and the ductility reduced due to the presence of high thermal stress and brittle precipitates. In addition, the tensile deformation mechanisms of joint and gradient samples are ductile cavities and brittle dissociation, respectively. The microhardness of the 316L-IN625 gradient material gradually increases along the deposition building direction, which is related to the solid solution and the precipitation strengthening of IN625.

ConclusionsThis study employed a level set method to establish a two-dimensional finite element model of nanosecond laser to simulate the forming process of titanium alloy micro-pit structure covering heat transfer, fluid flow, surface tension, and Marangoni effect. In a single pulse period, the Marangoni effect caused by the surface tension gradient significantly affects the formation of the crater structure during melting, vaporization, liquid phase migration, and solidification of the material. The formation of sputtered droplets arises from the combined effect of recoil pressure, surface tension, and thermal capillary force on liquid phase migration and sputtering. In the multipulse period, the differential surface tension of the ablation edge in the horizontal and vertical directions causes the height of the crater to increase significantly with the number of ablation; however, the width of the crater does not change significantly. Because the influence of plasma shielding on the incident laser was not considered in the model, it was only suitable for predicting the geometric size of the micro-pits when the number of ablation was less than 15 times.

ConclusionsThe deposited microstructure of SLM TC4 constitutes coarse β columnar crystals with martensite α′ and α″ as the intragranular substructures. The microstructure of SLM TC4 after solution aging heat treatment is bimodal, and a secondary α phase is generated during the aging process. During the cyclic annealing process, parts of the grain boundary α phase and lath α phase are broken to form an equiaxed α phase. After the cyclic spheroidizing annealing and solution aging treatment, the microstructure of the sample is mainly composed of the lath α phase, equiaxed α phase, and secondary α phase; the volume fraction of the equiaxed α phase is relatively high. The standard deviation of the mechanical property data of SLM TC4 is generally large, which is significantly reduced after the heat treatment. The strengths of the samples treated either solely by solution aging or a combination of cyclic spheroidizing annealing and solution aging are roughly equivalent. The sample plasticity obtained by the combined cyclic spheroidizing annealing and solution aging is better than that obtained by solution aging alone. After the heat treatment methods, the mechanical properties of the samples exceed the national forging standard. The plastic anisotropy of SLM TC4 depositions is high. However, the three heat treatment processes significantly reduce the plastic anisotropy. Among these processes, the solution aging treatment provides the deposited TC4 with the lowest anisotropy of the mechanical properties. SLM TC4 depositions have mixed fracture morphology, while the deposited TC4 after heat treatment shows a typical ductile fracture.

ConclusionsBy adjusting the process parameters of the ultraviolet microsecond laser, stable colors including black, blue, purple, purple-red, orange, and light yellow are induced on the surface of 304 stainless steel. Coloring mechanism of 304 stainless steel induced by the microsecond laser is discussed and believed to be the color of the oxide layer and the film interference effect. The HSB values of the color patches are predicted by using the Elman neural network for the given laser parameters. The predicted results show that the average relative errors of hue, saturation, and brightness are 4.04%, 13.33% and 4.05%, respectively. The colors of the processed pattern have a good consistency with the predicted colors.

ConclusionsThe study on the effect of laser power on the mechanical properties of laser cladded 27SiMn steels can be concluded that 1800 W is the optimum power for laser cladding. A laser cladded coating with good mechanical properties is obtained with a laser power of 1800 W, a scanning speed of 20 mm/s, a powder feeding rate of 18 g/min, a defocusing distance of 0 mm, and a spot diameter of 2 mm. The microstructure in the middle of the laser cladded layer of the specimen at 1800 W shows more cytosine crystals and a small number of dendrites and columnar crystals. The more cellular crystals can make the specimen less prone to fracture. The heat-affected zone of the laser cladded coating is the smallest, therefore the damage to the substrate is the lowest and the fracture of the tensile specimen is mainly ductile. Above all, the research results here can provide a good reference for the hydraulic support remanufacturing engineering practice.

ConclusionsIn this paper, the features and the stability of droplet transition during laser-MIG hybrid welding are analyzed, and a method for monitoring welding process stability based on SPE is proposed. Stable droplet trajectory and velocity can improve the uniformity of weld formation. When the welding is unstable, there is a disordered short-time logarithmic power spectrum, increasing SPE, and decreasing weld width and spreadability. The power spectrum of STFT and its SPE of arc area can effectively reflect the stability of the welding process. This method utilizes the arc light features and provides a new idea for monitoring the laser-MIG hybrid welding process.

ConclusionsBoth the laser energy density and scanning speed have a greater impact on the cleaning quality. The cleaning quality of the laser gradually becomes better with an increase in the laser energy density or decrease in the laser scanning speed. When the laser energy density and scanning speed are 4.45 J/cm2 and 8 mm/s, respectively, the top-coat can be completely removed and the primer remains intact, with the effect closest to the original thickness of the paint layer. When the laser energy density and laser scanning speed are 4.45 J/cm2 and 5.5 mm/s, respectively, the composite coating can be completely removed with the perfect microstructure of the anodic oxide film. Similar to those of the original anodic oxide film, the oxygen content of about 40% and the surface roughness Ra=1.138 μm are observed. When the parameter combination is 3.56 J/cm2 and 6 mm/s, the top-coat can also be completely removed, with the primer retained well. When the laser energy density and scanning speed are 4 J/cm2 and 5 mm/s, respectively, the composite paint layer can be completely removed, and the oxygen content of the anodic oxide film is about 34%. When the combination of parameters is 3.56 J/cm2 and 4.5 mm/s, the anodic oxide film produces elastic vibration stripping.

ConclusionsIn the study, we examine the influence of welding speed on bead appearance and low-temperature impact toughness of 440 MPa grade high-strength marine steel when laser-arc welding was used. Susceptibility to root humping increases with welding speed, and severe boot humping occurs at welding speed of 1.8 m/min. At the scanning speed of 1.2 m/min, the weld metal exhibits exceptional low-temperature impact toughness. At the low welding speed of 0.8-1.0 m/min, -40 ℃ sharp impact absorbed energy of the weld metal is low, owing to a lot of porosity in the weld metal. When the welding speed increases from 1.2 to 1.8 m/min, the number of acicular ferrite decreases while the amount of lath bainite increases, resulting in a steady decrease in the impact toughness.

ConclusionsIn this study, highly conductive Cu microstructures were formed on a glass substrate using femtosecond laser direct writing. As photon-absorbing nanoparticles, Si nanoparticles were added to the precursor solution. With the intensity ranging from 5.32×109 W·cm-2 to 8.51×109 W·cm-2 and the scanning speed ranging from 100 mm·s-1 to 500 mm·s-1, the Cu microstructures were formed on substrates. Metallic copper, Cu2O, and minor Si were found in the copper microstructures. The results show that the continuity of the microstructure, the proportion of Cu, and the conductivity of the microstructures all increased with increasing intensity or decreasing scanning speed. At the scanning speed of 100 mm·s-1, the lowest sheet resistance of 0.28 Ω·sq-1 and the lowest electrical resistivity of 4.67×10-6 Ω·m were obtained. The intensity was two orders of magnitude lower than that in previous work, and the direct writing efficiency was one to three orders of magnitude higher than that in previous work. Moreover, the line width of the microstructure was significantly smaller than the diameter of the laser spot.

ConclusionsMechanical properties of the SLM 316L sample have significant anisotropy. The impact absorbing energy of the sample prepared at room temperature is about 47% and 44% of that of the rolled plate, respectively, when the sampling direction is in the horizontal direction and the vertical direction. The tensile strength of the SLM samples prepared at room temperature under a vertical load is about 81.6% of that under a horizontal load. Preheating has little effect on the relative density and impact toughness. Preheating reduces microhardness by about 4%. After preheating, the tensile strength of the 316L sample formed by SLM decreases by about 4% and the elongation increases by about 6%. Under the experimental conditions in this paper, preheating has little effect on the fatigue life of the sample under a vertical load, but significantly improves the fatigue life of the sample under a horizontal load. The main reason may be that preheating can inhibit the formation of large-size defects.

ConclusionsIn this work, an online static magnetic field system for the SLM process is designed. An optical microscope and a scanning electron microscope are employed to examine the microstructures of the specimens, and a material testing machine is used for the mechanical property tests. Our findings show that applying a magnetic field can significantly improve the relative density of the formed sample. As the magnetic field strength increases from 0 to 0.3 T, the grain orientation changes from the strong (001) orientation to (001), (101), and (111) uniform orientations, while the texture index decreases from 6.843 to 5.718. Thus, to a certain extent, the anisotropy of grain orientation of GH3536 alloy is weakened. The results suggest that the change in grain orientation is mainly due to the generation of thermoelectric forces acting on the dendrites. Besides, the applied magnetic field makes the tensile strength and elongation of the sample along the scanning and deposition directions tend to increase, especially along the scanning direction. The tensile strength along the scanning direction under the 0.1 T and 0.3 T magnetic fields increases by 20 MPa and 70 MPa, respectively, and the elongation increases by 0.8% and 2.9%, respectively. At 0.1 T and 0.3 T, the differences in tensile strength along the scanning and deposition directions decrease by 14.1% and 47.5%, respectively, while the differences in elongation decrease by 11.1% and 55.3%, respectively. The static magnetic field can significantly weaken the anisotropy of the mechanical properties of SLM parts since the static magnetic field changes the grain orientation during the SLM process.

ConclusionsThe BCC 316L porous structure is prepared based on the LPBF technology. The compression process of this porous structure mainly experiences the elastic stage, platform stress stage and densification stage. By observing the morphology and measuring the geometric parameters of the porous structure, when the diameter of the rod is from 0.4 mm to 1.2 mm and the volume fraction is from 4.9% to 35.75%, the relative errors of diameter and volume fraction are from 15.00% to 6.08% and from 8.20% to 6.03%, respectively. It can be seen that the forming effect is good, and the contour error and surface sticking are the main causes of the error. The larger the size, the higher the forming accuracy. With the increase of rod diameter, the equivalent elastic modulus increases from 59.87 MPa to 3356.21 MPa, and the compressive yield strength increases from 1.02 MPa to 33.88 MPa. The research conclusions of the finite element analysis and the mechanical test are compared and analyzed. The average relative error of equivalent elastic modulus obtained by the finite element analysis and the mechanical test is 9.11%, and the average relative error of compressive yield strength is 7.86%. Both are within 10%. Therefore, the finite element model can effectively predict the mechanical properties of the 316L stainless steel body-centered cubic porous structure within a certain error range.

ConclusionsIn this paper, the surface microstructure of the laser shocked TC4 titanium alloy is analyzed by EBSD and TEM, respectively. The microstructure evolution law and the nanocrystal formation mechanism are revealed. Laser shock peening does not change the microscopic material composition, but it can refine and homogenize the original grains, transform the small-angle grain boundaries to the large-angle ones, reduce the texture pole density, and make the grain orientation be more random. The surface layer microstructure consists of nanocrystals, dislocation cells, high-density dislocations, and original coarse grains, in which the thickness of the nanocrystal layer is about 710.4 nm, and the overall influence depth is less than 100 μm. The surface nanocrystals are formed through the complex dislocation movement, which conforms to the continuous dynamic recrystallization mechanism. The surface crystal distortion energy is the largest and the temperature rise effect is the most prominent, so the recrystallization process is the most fully carried out and the grain refinement is the highest.

ConclusionsIn this study, the LSP surface treatment of a Ti80 alloy is implemented, and the corresponding microstructural evolution and properties are investigated systematically. After LSP, the surface grains of the Ti80 alloy are significantly refined, and many defects such as dislocation tangles, stacking faults, and deformation twins are formed. The strengthening effect of crystal defects combined with fine grain strengthening increase the surface microhardness by 21.7%. However, the large compressive residual stress is formed, resulting in enhanced strength and elongation, and the overall mechanical properties of the Ti80 alloy become better. Grain refinement provides more nucleation sites for the formation of passivation film of the Ti80 alloy, while the compressive residual stress makes the passivation film denser and less susceptible to destruction, resulting in a positive shift of the corrosion potential of the Ti80 alloy in the 5 mol/L HCL solution by 119 mV. The corrosion current density is reduced by 0.52 μA·cm-2 and the corrosion rate is reduced by 0.16 mm·a-1, therefore the anticorrosion property is improved.

ConclusionsWhen the heat input of the manganese steel in laser welding is 150500 J/mm, the weld forming is better. When the heat input is small, the weld microstructure is martensite, and with the increase of heat input, a small amount of bainite is generated in the weld. The prior-austenite grain boundary, martensitic packet boundary, and block boundary in the weld microstructure of the medium manganese steel can hinder crack propagation. The crack propagation energy in the weld zone is inversely proportional to the average effective grain size (>15° high-angle grain boundary) and positively proportional to the high-angle grain boundary density. The impact toughness of the weld at -40 ℃ increases first and then decreases with the increase of heat input. When the welding heat input is 150 J/mm, the dislocation group and the twin martensite structure reduce the crack initiation energy and make it easy to crack, and the fracture is a cleavage fracture. When the heat input is 300 J/mm, the effective grain size decreases, the high-angle grain boundary density is the highest, the crack initiation and propagation energies increase, and the fracture is a ductile fracture. When the heat input is greater than 300 J/mm, the effective grain size increases, the high-angle grain boundary density decreases, and the crack propagation energy decreases. When the heat input is 500 J/mm, the high-angle grain boundary density is the lowest, the crack propagation energy decreases sharply, and the fracture is a cleavage fracture.

ConclusionsThe 55NiTi+5Ni coatings are successfully fabricated on the 316L substrate via laser cladding, which provides the possibility to use mixed 55NiTi and single Ni powder to replace 60NiTi alloy powder. The effects of Ni addition on the microstructures and properties of 55NiTi coatings are investigated, and the following conclusions can be drawn. The addition of Ni leads to smaller and denser microstructures, and the average grain size reduces by about 20%. NiTi and Ni3Ti are the major phases in the coatings, which exist in eutectic with lamella form. The proportion of Ni3Ti phase in the coatings has been improved with the addition of Ni. Wear resistance has been improved, the hardness of the coatings reaches 830 HV which is 7.2% higher than that of the 55NiTi coating, and the wear mass loss is reduced by 10%. The 55NiTi+5Ni coating shows excellent corrosion resistance, the corrosion current density and corrosion rate are reduced 50% compared with those of the 55NiTi coating. The enhancement of the coating surface properties is mainly attributed to the increase of the second phase proportion and the solid solution strengthening effect caused by the addition of Ni.

ConclusionsThe maximum-hardened layer depth of 6.3 mm can be obtained from the laser-induction hybrid quenched process on 42CrMo steel. The results show that the specimen with the hardened layer depth of 6.3 mm has the lowest surface damage, shallowest surface wear scar depth, shortest cross-sectional crack length, and best rolling contact fatigue performance among three specimens. After laser-induction hybrid quenching, a certain residual compressive stress exists on the specimen surface, which can improve the rolling contact fatigue performance of the material. As the depth of the hardened layer increases, the fatigue failure type of laser-induction hybrid quenched 42CrMo steel under heavy load conditions changes from external cracking to internal cracking and spalling. The angle between the cracks and surface decreases from 90° to 15°. While the crack propagation angle reduces, the crack extension becomes smoother and the rolling wear and fatigue damage of the specimen are alleviated.