View fulltext

View fulltext

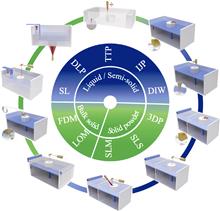

As an emerging manufacturing technology, additive manufacturing technology, also known as 3D printing technology, has received extensive attention in recent years. Additive manufacturing technology has great potential in the industry of high-performance ceramics. It is expected to break the technical bottle neck of the traditional manufacturing technologies used for ceramic fabrication and greatly improve the flexibility of design and manufacturing of high-performance ceramics. This will provide a transformative impetus for the development of the manufacturing technology of the high-performance ceramic materials. Polymer-derived ceramics (PDCs) are a class of polymers obtained by chemical methods and can be transformed into ceramics by heat treatments, i.e., pyrolysis. Due to the good machinability and formability of the PDC materials themselves, the pre-forming of the designed target structures can be easily realized. These structures might not be possible with traditional ceramic manufacturing. Therefore, the combination of PDCs and additive manufacturing technology has attracted great attention from researchers. This review introduces characteristics of the additive manufacturing technology used for preceramics. Based on that, the present research status, trends and applications are also systematically described and discussed. The challenges and future directions of the additive manufacturing of polymer-derived ceramics are given for the guidance of future development.

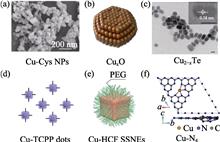

Natural enzymes play an important role in maintaining normal life activities, but suffer in their inherent instability, harsh reaction conditions and high purification costs, which limit their wide applications in vitro. Compared to natural enzymes, nanozymes with high stability, low cost, and ease of structural regulation and modification attract the great interests and are widely applied to biomedicine, environmental control, industrial production and other fields due to their enzyme-like activities and selectivity. As an essential element and one of the active central metals of natural enzymes in the human body, copper-based (Cu-based) nanozymes have received extensive attentions and researches. This review focused on the classification of Cu-based nanozymes, such as Cu nanozymes, Cu oxide nanozymes, Cu telluride nanozymes, Cu single-atom nanozymes, and Cu-based metal organic framework nanozymes. Then this review described the enzyme-like activities and catalytic mechanisms of Cu-based nanozymes, and also summarized the applications of Cu-based nanozymes, including biosensing, wound healing, acute kidney injury, and tumors. The challenges and future development direction of Cu-based nanozymes were proposed.

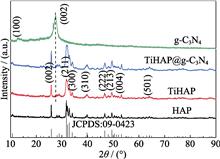

A composite photocatalyst (TiHAP@g-C3N4) consisting of Ti doped hydroxyapatite and g-C3N4 was synthesized through hydrothermal route. Its structure and optical property were characterized by various means and photocatalytic activity was evaluated through methyl orange (MO) degradation experiments. Results show that short rod-shaped TiHAP in the sample grows on the surface of g-C3N4. Both TiHAP and g-C3N4 maintain their original crystal shape and chemical structure. As-prepared TiHAP@g-C3N4 is of high purity with specific surface area of 107.92 m2/g, which is increased about 135% and 44% as compared with sole TiHAP and sole g-C3N4, respectively. The highest MO degradation rate of 96.35% is achieved within 120 min by TiHAP@g-C3N4 at the concentration of 1.0 g/L and pH 7. More than 80.02% of MO was removed in every of three cyclic tests, demonstrating good and stable photocatalytic performance of TiHAP@g-C3N4. Holes (h+) play the largest role in the MO degradation process, followed by ·O2- and ·OH. The constructed TiHAP@g-C3N4 heterojunction enhances light absorption, improves separation efficiency of photoelectrons-h+, and preserves more redox-prone TiHAP valence band h+ and g-C3N4 conduction band electrons. Therefore, as-synthesized TiHAP@g-C3N4 can be a promising catalyst in photocatalytic degradation.

Ammonia with low cost, easily liquefied and high volumetric energy density is an attractive carbon-free fuel. Utilizing ammonia as anodic fuel, direct ammonia fuel cells are showing great interests to researchers. However, such amazing fuel cell device is limited by the sluggish anodic ammonia oxidation reaction. In this work, PtIr alloy aerogels with a three-dimensional porous network structure were prepared by nanoparticles (NPs) self-assembled under a simple and surfactant-free conditions. This structure provided a rich open interconnected proton transport channel and additional catalytically active sites which contributed to the dehydrogenation process of NH3 molecules in ammonia electrocatalytic oxidation. An optimal AOR activity was achieved at the 80/20 molar ratio of Pt/Ir. Effects of NH3 concentration and operating temperature on catalyst's ammonia oxidation performance were studied, which revealed that the AOR performance of Pt80Ir20 alloy aerogel was improved with the increase of ammonia concentration or operating temperature. For example, the mass specific activity, at 0.50 V of the Pt80Ir20 alloy aerogel, was estimated to be 44.03 A·g-1, which was about 4 times as that of the ammonia concentration at 0.05 mol/L. In the case of operating temperature effect, the mass activity was estimated to be 148.73 A·g-1, which was almost 12 times as that of the temperature rising (from 25 ℃) to 80 ℃. Encouragingly, the onset potential of the optimal Pt80Ir20 alloy aerogel catalyst displayed about 40 mV reduction during such a temperature change. Further calculations using the Arrhenius equation showed that its activation energy was reduced by about 9.43 kJ·mol-1 as compared with commercial Pt/C. Moreover, its AOR stability was improved as evidenced by a loss of ~50.6% mass activity after 2000 potential cycles when compared with commercial Pt/C (~74.9%).

Ti3C2Tx MXene is a potential adsorbent of heavy metal ions due to its two-dimensional layered structure and abundant surface functional groups. However, it has disadvantages of limited layer spacing and poor stability in aqueous solution. Here, the modification strategy of Ti3C2Tx was explored to improve its chemical stability and ion adsorption capacity among which Fe3O4-Ti3C2Tx(FeMX) adsorbent with different doping amounts of Fe3O4 were prepared by one-step hydrothermal method. The results showed that the maximum theoretical Pb(II) adsorption capacity of FeMX adsorbent could reach 210.54 mg/g. Its adsorption mechanism was further revealed that Fe3O4 nanoparticles were evenly dispersed and intercalated between Ti3C2Tx nanosheets, which effectively increased specific surface area and layer spacing of Ti3C2Tx nanosheets, leading to improving Pb(II) removal ability. Therefore, this study provides a promising route for developing MXene matrix composites with excellent heavy metal ion adsorption properties.

Drinking water contaminated with arsenic for a long time will inevitably lead to serious human health problems. Suitable adsorbent for arsenic removal from water is an urgent but a challenging task. In this study, halloysite nanotubes-supported ZrO2 (ZrO2/HNT), a novel and efficient arsenate adsorbent, was prepared using a straightforward hydrothermal method. Its morphology and structure were characterized. ZrO2 nanoparticles with monoclinic phase were well dispersed on the outer walls of halloysite nanotubes. And the ZrO2/HNT could effectively remove As(V), achieving adsorption equilibrium within 30 min. The saturation As(V) adsorption capacity was 27.46 mg/g at 25 ℃. Its adsorption capacity decreased with the increase of the solution’s pH. Coexistent ions (except phosphate) showed little effect on adsorption performance of As(V). The As(V) adsorption kinetics fitted well with pseudo-second-order modeland the As(V) removal processes were endothermic which was verified as chemisorption reactions based on calculation of Gibbs free energy and Dubinin-Radushkevich (D-R) isotherm model. Fourier transform infrared (FT-IR) and X-ray photoelectron spectrometer (XPS) study indicated that the As(V) adsorption processes mainly proceeded through ligand exchange between As(V) and hydroxyl groups on the surface of ZrO2 in the ZrO2/HNT and formation of inner-sphere surface complexes. This study suggest that the as-synthesized ZrO2/ HNT is a potential candidate for practical applications of As(V) removal from water.

In practice, adsorbents such as 13X have strong hydrophilicity due to their low Si/Al ratio, whose competitive adsorption between vapour and volatile organic compounds (VOCs) often impairs the actual removal effect of VOCs on the adsorbents. Here, 13X was modified using CTABr as a templating agent and tetraethoxysilane (TEOS) as a silica source.Based on this modified 13X, a core-shell composites with 13X core and a mesoporous silica shell, named as 13X@SiO2, was therefore synthesized. Its adsorption performance was tested by using toluene as a probe molecule under different humidity conditions on a penetration experimental device, compared with that of the pristine 13X. The results show that the adsorption capacity of sample 13X@SiO2-2.6 (2.6 mL TEOS added in the preparation) was about 18% higher than that of 13X original sample under dry conditions. At 30% and 50% relative humidity, the optimum adsorption capacity of 13X@SiO2 was increased by about 53% and 90%, respectively. In order to test the stability and reusability of the adsorbents, twice regeneration of sample 13X@SiO2-2.6, treated for 2 h in situ desorption at 350 ℃, were performed, and the result showed that the regenerated sample 13X@SiO2-2.6 still retained 90% of the original toluene adsorption capacity.

Environmental barrier coatings (EBCs) are expected to be applied to the hot-section components of a new generation of high thrust-to-weight ratio aero-engines. Rare-earth silicates have been acknowledged as promising alternatives to EBC materials due to their superior high-temperature phase stability, suitable coefficient of thermal expansion, and long durability in water vapor. However, the calcium-magnesium-alumino-silicates (CMAS) molten salt corrosion under service conditions has become a bottleneck that limits the application of rare-earth silicates in EBCs. Factors such as the composition of CMAS and the crystal structures of rare-earth silicates have a significant impact on their corrosion behavior. In this paper, X1-Gd2SiO5 and X2-RE2SiO5 (RE=Y, Er) coatings with different crystal structures, were prepared by atmospheric plasma spraying (APS) technique. Their corrosion behaviors and mechanisms of the three kinds of coatings under CMAS melt environment at 1400 ℃ were explored. Results showed that the corrosion resistance of X2-RE2SiO5 coatings were better than that of X1-Gd2SiO5 coating due to their phase compositions and stability of crystal structure. After corrosion by CMAS, X1-Gd2SiO5 coating dissolved in CMAS melt and formed apatite phase, while the X2-RE2SiO5 coatings not only formed apatite phase, but also formed garnet phase from reaction of the RE2O3 in the coatings with Al2O3 in CMAS. Formation of generate garnet phase could increase relative content of CaO and SiO2 in CMAS, and promote formation of dense apatite layer, thereby improving corrosion resistance. This study provides a strategy for designing EBC systems with excellent CMAS corrosion resistance.

The corrosion resistance of LTCC (Low Temperature Co-fired Ceramics, LTCC) materials to acid/alkali bath in electroplating and electroless plating is an important characteristic that needs to be paid attention to in practical application. In this work, the effects of HCl, H2SO4 and NaOH concentration and immersion time on the corrosion behavior of Ca-B-Si based LTCC materials were studied. The results show that when LTCC samples are soaked in acid solution, the weight loss of samples increases firstly and then decreases with the increase of acid solution concentration. The weight loss in 1.00 mol/L hydrochloric acid solution is up to 54.96%, while that in 0.10 mol/L sulfuric acid solution is only 8.80%. However, no obvious corrosion is observed in the alkaline solution. The crystal phase of CaB2O4 and CaSiO3 in LTCC material dissolves in the acid solution to induce corrosion. With the increase of acid solution concentration, formation of Si-rich alteration layer on the surface of the sample after corrosion becomes faster, while the passivation alteration layer makes the weight loss in higher concentration of acid solution relatively low. Apparent activation energies of LTCC material in 1 mol/L hydrochloric acid solution, and 0.1 mol/L sulfuric acid solution are 20.38, 5.43 kJ/mol, respectively, indicating the corrosion rate of LTCC material in hydrochloric acid solution is higher than that in sulfuric acid solution. Combined with chemical corrosion reaction kinetics and thermodynamic results, this study reveales that the corrosion mechanism of LTCC materials in acid solution is dominated by ion exchange and hydrolysis reaction.

Controlling the structure and properties of low-density C/C porous preforms is the key to the preparation of C/C-SiC composites with excellent friction and wear properties. In this study, C/C porous preforms prepared by chemical vapor infiltration were subjected to high temperature heat-treatment at 2100 ℃. C/C-SiC composites were prepared by reactive melt infiltration. Effects of high temperature heat-treatment of C/C porous preforms on microstructures, thermal properties and tribological properties of C/C-SiC composites were investigated. The results showed that the porosity and graphitization degree of the C/C porous performs increased after high temperature heat-treatment at 2100 ℃. The C/C-SiC composites have a higher density (2.22 g/cm3), and the porosity is reduced from 5.1% to 3.4%, the phase content of SiC ceramic is increased by 11.9%. The mean free path of phonons is larger when C/C porous preforms have a higher degree of graphitization, resulting in thermal conductivity at room temperature being increased by 2.1 times, and the thermal conductivity at 1200 ℃ being increased by 0.2 times. Wear surface of C/C-SiC composites forms a continuous and stable friction film, which is attributed to the fact that the PyC after high temperature treatment is softer and easier to be extruded into a film. Thus, the friction coefficient is more stable, and the wear rate is reduced under the test loads of 3, 6 and 9 N, by 47.8%, 41.9% and 11.7%, and the average friction coefficients are 0.47, 0.38 and 0.39, respectively. Therefore, high temperature heat-treatment of the C/C porous preforms can improve the thermal conductivity of the C/C-SiC composites, which exhibits a more stable friction coefficient and more wear-resistant.

Polycrystalline near stoichiometric SA type SiC fibers have a prospective application in the fields of the new generation aero engine and hypersonic vehicles due to their excellent temperature resistance. In this work, microstructure evolution, tensile strength as well as fracture behavior of the second-generation domestic F-II SiC and the third-generation SA (F-III) SiC fibers before and after heat treatment were studied. The results showed that F-III fiber was mainly composed of β-SiC grains (~200 nm) and a small amount of free carbon, while F-II fiber was composed of β-SiC grains (~5 nm), free carbon and amorphous SiCxOy phase. Compared with the F-II fiber, the F-III fiber showed lower tensile strength at room temperature, owing to their larger grain size and pores. However, after heat treatment at 1800 ℃, the structure and strength of F-III fiber remained almost unchanged, while the strength of F-II fiber decreased sharply due to decomposition of SiCxOy phase and grain growth. The excellent high temperature resistance of SA type fiber could be attributed to high crystallinity, large grain size, low carbon and oxygen content in microstructure and composition.

Microstructure plays a key role in tuning physical properties of materials. Here YbAl3 materials with high figure of merit ZT of 0.35 at 300 K was directly synthesized with Yb and Al pure powders through one-step spark plasma sintering process in 10 min. The excellent thermoelectric performance is attributed to the simultaneous reduction in the lattice thermal conductivity by 47% and electronic thermal conductivity by 27% at 300 K. The remarkable decrease in the electronic thermal conductivity is ascribed to the enhanced scattering of electrons by nanocrystals with 5-20 nm in diameter, strip-like non-crystal with several nanometers in width and various atomic-scale distortions. The substantial decline in the lattice thermal conductivity originates from the enhanced scattering of phonons due to multi-scale microstructures spanning from nanoscale to mesoscale. This work demonstrates that one-step spark plasma sintering process is an efficient strategy to rapidly synthesize YbAl3 materials with multi-scale microstructures and enhanced thermoelectric performance.

Besides its application as nonlinear optical devices, La2CaB10O19 (LCB) crystal has been extensively studied as a host crystal due to excellent properties. Nevertheless, rare-earth (RE) ions doped LCB crystals for ultraviolet (UV) lasers have not been studied yet. In this work, Ce3+ doped La2CaB10O19 (Ce3+:LCB) crystal with the size of 40 mm×21 mm×6 mm was grown by top-seeded solution growth (TSSG) method. Its lattice parameters are slightly different from that of the LCB crystal, and its X-ray rocking curve indicates that the Ce3+:LCB is of high crystalline quality. Transmittance spectrum and UV absorption spectrum measured at room temperature show intense absorption in the ranges of 200-288 nm and 305-330 nm,and Sellmeier equations for the refractive indices were determined by least-squares method. The excitation and fluorescence spectra show that there are two broad excitation peaks at 280 nm and 316 nm, corresponding to transitions of Ce3+ ions from 4f to 5d. Four emission peaks were obtained at 290, 304, 331, and 355 nm, which correspond to transitions from 5d state to 2F5/2 state and 2F7/2 state. Ce3+:LCB crystal exhibits high thermal conductivity (6.45 W/(m·K)) at 300 K, and keeps good thermal stability with the increase of temperatures. Its thermal expansion coefficients and lattice parameters of c direction linearly enlarge from 2.94×10-6 /K and 0.91240 nm to 5.3×10-5 /K and 0.91246 nm in the temperature range from 358 K to 773 K, respectively. These results demonstrate that Ce3+:LCB crystal has excellent optical properties and good thermal stability, which is conducive to its application for UV lasers.