View fulltext

View fulltext

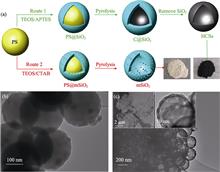

Hollow carbon spheres (HCS) with controllable diameter and shell thickness using a simple encapsulation pyrolysis synchronous deposition method is reported. This method changed the polystyrene spheres (PS), a widely used sacrifice hard template, into carbon by a pyrolysis and synchronous deposition process in the hermetical silica shell, without any cross-linking agent and catalyst, simplifying synthesis, and lowering costs. The obtained HCS exhibited uniform spherical morphology with tailorable particle size (190-1600 nm) and well controlled hollow voids. Moreover, HCS samples with precisely tuned thickness (4.5-13.5 nm) were obtained only by changing the silica precursor amount. The resultant HCS showed promising potential for applications in cefalexin adsorption with capacity of 291 mg·g -1. Therefore, this synthetic strategy may offer an efficient production route to commercial applications for HCS.

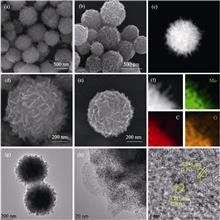

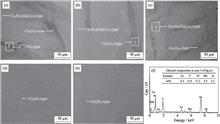

Lanthanum-substituted LaxSr2-3x/2Fe1.5Ni0.1Mo0.4O6-δ (LaxSFNM, x=0, 0.1, 0.2, 0.3, 0.4) oxides were synthesized by the solid-state reaction method, and investigated as potential anodes for Solid Oxide Fuel Cells(SOFC). X-ray diffraction patterns of as-synthesized powders confirm the formation of the cubic perovskite structure. Reduction in H2 promotes the segregation of nano-scale metallic Fe-Ni alloy particles on the grain surfaces. Scanning electron microscopy observations indicate that increasing La 3+ dopants results in a decrease in the density of the exsolved nanoparticulates. Based upon impedance measurements on symmetrical fuel cells, the anode polarization resistance decreases with the La 3+ dopant increasing, and attains a minimal value of 0.16 W·cm 2 for La0.3SFNM at 750 ℃, followed by a slight increase to 0.17 W·cm 2 for La0.4SFNM. The highest catalytic activity of La0.3SFNM toward electro- oxidation of hydrogen fuels could be ascribed to the synergy between the exsolved Fe-Ni alloy nanoparticulates and the supporting LaxSFNM oxides. Thin La0.9Sr0.1Ga0.8Mg0.2O3 (LSGM) electrolyte fuel cells with La0.3SFNM anodes and SmBa0.5Sr0.5Co2O6 cathodes exhibit the highest power densities, e.g., 1.26, 0.90 and 0.52 W·cm -2 at 750, 650 and 550 ℃, respectively. These results demonstrate La0.3SFNM oxide as a promising high performance SOFC anode.

Carbon nanospheres enriched with α-MoC1-x nanocrystalline (α-MoC1-x/CNS) were synthesized by self-assembly and applied as a mediator for the surface of commercial polypropylene (PP) separator. Compared with pristin PP separator, the cycling stability and rate performance of the lithium-sulfur batteries with the modified α-MoC1-x/CNS-PP separator are significantly improved and the battery with α-MoC1-x/CNS-PP separator exhibits an initial discharge capacity of 1129.7 mAh/g at 0.5C and retains 855.5 mAh/g after 100 cycles with above 98% Coulombic efficiency. Remarkably, the capacity loss rate is only 7.7% after 48 h static storage. Combined with the morphology and XPS analysis of α-MoC1-x/CNS, it is found that the designed α-MoC1-x/CNS-PP separator prevents the migration of lithium polysulfide to the anode during the process of charge and discharge in lithium sulfur batteries. Formations of Mo-S bonds, thiosulfate and polythionate are attributed to the contact between lithium polysulfide and α-MoC1-x/CNS, which further restrains active material in cathode region and improves the performance of lithium- sulfur batteries consequently.

Photocatalysis technology possesses great potential in the field of oxidation of nitrogen oxides due to the low energy costs and little secondary pollution. Bismuth carbonate (Bi2O2CO3, BOC)/polypyrrole (PPy) was prepared at room temperature to remove NO under visible light irradiation. After being decorated with PPy, the NO removal efficiency of BOC is enhanced from 9.4% to 20.4% while the generation of NO2 is reduced from 2% to approximately zero, which are attributed to the oxygen vacancy formed at the interface between BOC and PPy via interfacial hydrogen bonding. Photocurrent and electrochemical impedance spectra indicate that oxygen vacancies promote the separation and migration of photo-induced electrons and holes over BOC, hence improve its photocatalytic activity. Furthermore, the presence of oxygen vacancy promotes the formation of more ·O2-, and then improve the NO oxidation activity and safety of BOC together with ·OH.

La0.3Y0.7Ni3.4-xMnxAl0.1(x=0-0.5) hydrogen storage alloys were prepared by vacuum arc melting followed by homogenized annealing. Effect of Mn element on the microstructure, hydrogen storage behavior and electrochemical properties were systematically investigated via different methods. The results show that the microstructure of the annealed alloys closely relates to the Mn content. Higher Mn content facilitates the formation of Ce2Ni7 type phase until single phase structure of Ce2Ni7- type forms in the alloys with x≥0.3. With the increment of Mn content, the unit cell parameters (a, c) and unit cell volume (V) of Ce2Ni7- type phase increase, resulting in the hydrogen absorption platform pressure of the alloys decreasing from 0.079 MPa to 0.017 MPa and the hydrogen storage capacities reaching 1.268wt%-1.367wt%. The electrochemical properties are significantly improved with the addition of Mn. La0.3Y0.7Ni3.25Mn0.15Al0.1 alloy exhibits the highest discharge capacity (390.4 mAh·g -1). The capacity retention S100 of the alloys with x=0.15 and 0.5 are 86.03% and 88.01%, respectively, presenting good cycle stability. Meanwhile, high rate discharge ability (HRD900) of the as-prepared alloys is 71.53%-87.73%. It is shown that electrochemical reaction kinetics of the alloy electrodes is controlled by both the electron transfer at the electrode/ solution interface and the diffusion of hydrogen atoms in the alloy bulk.

LiLuF4 single crystals doped with Ce 3+ ion of 0.1mol% and Yb 3+ ion of concentration varying from 0 to 2.0mol% were successfully synthesized by an improved Bridgman method. Intense near-infrared emission at around 1020 nm, attributed to the 2F5/2→ 2F7/2 transition of Yb 3+, and ultraviolet emission of Ce 3+ at 300-350 nm (5d→4f) was observed using excitation at 291 nm. Influence of Yb 3+ ions concentration on the spectroscopic properties of Ce 3+/Yb 3+ co-doped LiLuF4 single crystal and the mechanism of energy transfer from Ce 3+ to Yb 3+ ions were explored through optical absorption and emission spectra. The temperature dependent emission indicated that the emission intensity constantly decreases with the increase of temperature from 298 to 443 K due to the enhancement of non-radiative quenching at high temperature. Ce 3+/Yb 3+ co-doped LiLuF4 single crystals mainly emit in the ultraviolet and near-infrared ranges. This unique property may be suitable for applications in anti-counterfeiting techniques and public security affairs.

LED has the advantages of high efficiency, energy saving and environmental protection. It is widely used in the field of lighting. Improving the luminous efficiency of LED has always been a research difficulty and hot spot in this field. To reduce the total reflection phenomenon between GaN material and air and to improve the light extraction efficiency, fabrication and properties of the anodized aluminum oxide (AAO) nanostructured LED device were studied. Through inductively coupled plasma (ICP) etching process, large-area ordered pore nanostructure arrays were successfully fabricated on the surface of p-GaN layer, and the quasi-photonic crystal structure with apertures of 250-500 nm and pore depths of 50-150 nm were obtained. The crystal structure greatly increases the luminous intensity of the LED, and the nano-array LED with pore diameter of 400 nm and depth of 150 nm is improved by 3.5 times in contrast to the LED without the nano-array.

The synergy of plasma and catalytic materials for CO2 methanation provides the possibility for CO2 reuse. The preparation method of catalytic materials plays an important role on their structure and performance. In this work, Ru/γ-Al2O3-P and Ru/γ-Al2O3-T catalytic materials were prepared by atmospheric-pressure H2 plasma reduction and H2 thermal reduction, respectively, using Ru/γ-Al2O3 precursor prepared by incipient wetness impregnation. The catalytic activity of Ru/γ-Al2O3 prepared by different methods was evaluated during atmospheric-pressure plasma reduction for CO2 methanation reaction. Different techniques were used to investigate the effect of preparation methods on the structure of Ru/γ-Al2O3, analyze the influences of structural factor on the catalytic activity of Ru/γ-Al2O3, and discuss the preparation mechanism of Ru/γ-Al2O3-P and Ru/γ-Al2O3-T. The results show that the CO2 conversion of γ-Al2O3 support is 24.8% under the combination of atmospheric-pressure plasma, and the main product is CO. However, the main CO2 catalytic product of Ru/γ-Al2O3 is methane under the combination of atmospheric-pressure plasma. CO2 conversion over Ru/γ-Al2O3-P is 77.3%, which is higher than that over Ru/γ-Al2O3-T (69.9%). Higher catalytic activity of Ru/γ-Al2O3-P is ascribed to the higher metallic Ru ratio and Ru/Al atomic ratio, as well as the smaller and higher dispersion of Ru nanoparticles. This work proves that highly active supported metal catalytic materials can be prepared by atmospheric-pressure H2 plasma.

The ammonia selective catalytic reduction (NH3-SCR) technology is still necessary to further develop denitration catalytic materials which have good catalytic activity, high stability and environmental friendliness at relatively low temperature (2 for low temperature NH3-SCR of NO. The catalysts were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), nitrogen adsorption-desorption, X-ray photoelectron spectroscopy (XPS), temperature programmed reduction or desorption (H2-TPR, NH3-TPD). The catalytic results show that as compared with pure Mn-Fe-O sample, Mn-Fe-O modified with suitable CeO2 content shows much better performance for NH3-SCR with 95% conversion of NO and a high N2 selectivity at 80 ℃ under the same reaction conditions. CeO2 modification increases the content of Fe 3+, Mn 3+ and Mn 4+, and the number of surface acid sites on the surface of Mn-Fe-O oxide, which contribute to the adsorption of NH3 and the catalytic reaction. In addition, redox reactions among Fe 2+/Fe 3+, Mn 2+/Mn 3+/Mn 4+ and Ce 3+/Ce 4+ pairs improve the redox ability and stability of the catalyst.

Ethylene is the main factor of postharvest spoilage of fruits and vegetables. Therefore, how to reduce or remove the ethylene released during the storage of fruits and vegetables is a problem to be solved. In this study, a series of nickel foam supported TiO2/WO3 were prepared by Sol-Gel method. The samples were characterized by different methods. The photocatalytic degradation activity of ethylene under ultraviolet light irradiation was investigated. The results show that TiO2/WO3 film is successfully supported on the nickel foam, and there formed heterojunction between TiO2 and WO3, which efficiently enhanced the separation and transfer rates of photogenerated electron and hole. The narrowed band-gap also leads to a red shift of optical absorbance and high photoactivity. The photocatalytic activity and stability of TiO2/WO3 were excellent under UV light irradiation. When the mass percentage of WO3 is 6% of TiO2, the photocatalytic ethylene degradation of the TiO2/WO3 composite film reaches maximum, and the degradation rate constant is almost 9.8 times as that of TiO2. The mechanism of photocatalytic degradation of ethylene by TiO2/WO3 supported on nickel foam under ultraviolet light irradiation was also discussed.

Three-dimensional five-way braided C/C composites were prepared by chemical vapor infiltration using ethanol and methane as precursors. Their microstructure of the composites was analyzed by polarizing microscope. The static bending properties and fatigue behavior of prepared composites were investigated. Effects of loading cycles on bending strength and mechanical behavior of the prepared composites were studied. Results show that high texture C/C composites can be successfully fabricated by using mixed precursors. Average bending strength of the composites is 379.2 MPa, and their fatigue limit is 80.3% of the static bending load. Under cyclic loading, the flexural strength of C/C composites increases in different cycles. The bending strength is increased by 16.8% after 10 5 cycles. "Yield zone" of the bending bearing capacity of the material increases firstly and then decreases with the increase of the cyclic loading, which is related to the bonding state of fiber-matrix and matrix-matrix in the fatigue process.

The acoustic emission data collected during room temperature tensile test of 2D-C/SiC composites were analyzed by hierarchical clustering and unsupervised pattern recognition method based on an improved genetic algorithm. Combined with the SEM observation on the fracture surface, five damage modes were identified and their typical acoustic emission characteristics were obtained. According to the analysis of energy distribution, cumulative event number and cumulative energy of different damage modes, the damage evolution process of C/SiC composites can be divided into four stages. The first stage (damage initiation stage) shows mainly matrix microcracks and interface debonding. In the second stage, matrix crack reaches saturated and then causes a considerable quantity of interlaminar delamination and fiber failure. The third stage is a gradual damage development stage and all kinds of damage keep occurring except the breakage of fiber bundles. In the last stage, a large amount of fiber bundles break and the sample eventually fails.

To reduce the cost of HA and improve degradation performance of HA, oyster shells were used as raw materials to prepare CaCO3/ hydroxyapatite (HA) composite materials by a hydrothermal method. Phase analysis and SEM/TEM observation revealed that as-prepared CaCO3/HA composites had a morphology of HA nanoparticles growing on the lamellar CaCO3. Three kinds of CaCO3/HA composites (20%HA、40%HA、60%HA) with HA content of 20%, 40% and 60% were prepared by controlling the proportion of calcium and phosphorus. The actual content of HA in three obtained different composites, determined by ICP, were 17.52%, 34.30% and 43.24%, respectively. With the increase of HA content, the specific surface area and thermal stability of CaCO3/HA composite are improved. Samples were immersed in PBS simulated body fluid for 14 d to evaluate their in vitro degradation ability. The results showed that degradation rates of three kinds of composites with different HA contents (20%HA, 40%HA and 60%HA) were 15.2%, 12.0% and 10.8%, respectively. The degradation rate decreased with the increase of HA proportion in the composite. All data indicates that the hydrothermal synthesis of CaCO3/HA composite can control the conversion degree of HA and then adjust the degradation rate of CaCO3/HA composite by designing the ratio of calcium and phosphorus elements, which have potential application in orthopedics.

Chromogenic materials are capable of optical change reversibly in response to physical stimuli (e.g., electric field, temperature, illumination, and atmosphere). Among them, electrochromic materials are expected to be widely used in smart windows, screen displays, multi-functional energy storage devices and other fields due to their characteristics such as large adjustment range, fast response rate, high coloring efficiency and good cycle stability. However, compared with semi-solid-state electrochromic devices that are difficult to package and organic electrochromic materials that are prone to denaturation and failure, inorganic all-solid-state electrochromic materials and devices have better comprehensive application. This paper focuses on the typical inorganic all-solid-state electrochromic materials and devices, presents a brief review on the current preparation methods of each structure layer of electrochromic devices and compares its advantages and disadvantages, introduces in detail the main alternative electrochromic materials and its key performance evaluation index, and explains the principle of several representative electrochromic devices, proposes to use transparent flexible electrodes with both high light transmittance, low surface resistance and excellent bending fold to replace the traditional rigid substrate in order to realize multi-field responsible device application development. Finally, the application prospect of inorganic all-solid-state electrochromic devices is prospected from the perspective of performance bottleneck, process difficulty and industrialization opportunity, which provides reference for the industrialization process of electrochromic devices.

The third generation SiC fibers have near-stoichiometric composition and polycrystallinity with high density. Compared with the first and second generations, they have obvious improvements in heat-resistance, creep-resistance and radiation-resistance. Accordingly, they have more advantages and broader prospects in engineering applications, especially in the nuclear field. In this paper, the fabrication and performance characteristics of the third generation SiC fibers are introduced and compared. The applications of the third generation SiC fibers in the field of nuclear energy are reviewed, and the development prospects are prospected.