View fulltext

View fulltext

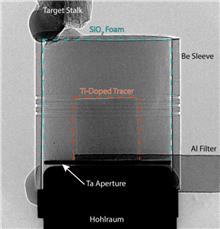

Targets have been developed to measure supersonic radiation transport in aerogel foams using absorption spectroscopy. The target consists of an aerogel foam uniformly doped with either titanium or scandium inserted into an undoped aerogel foam package. This creates a localized doped foam region to provide spatial resolution for the measurement. Development and characterization of the foams is a key challenge in addition to machining and assembling the two foams so they mate without gaps. The foam package is inserted into a beryllium sleeve and mounted on a gold hohlraum. The target is mounted to a holder created using additive manufacturing and mounted on a stalk. The manufacturing of the components, along with assembly and metrology of the target are described here.

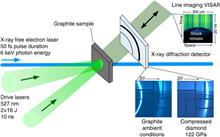

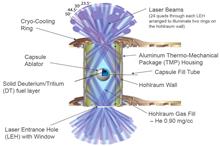

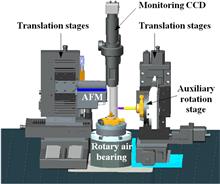

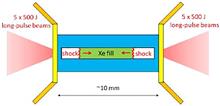

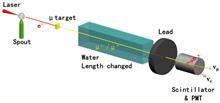

A number of laser facilities coming online all over the world promise the capability of high-power laser experiments with shot repetition rates between 1 and 10 Hz. Target availability and technical issues related to the interaction environment could become a bottleneck for the exploitation of such facilities. In this paper, we report on target needs for three different classes of experiments: dynamic compression physics, electron transport and isochoric heating, and laser-driven particle and radiation sources. We also review some of the most challenging issues in target fabrication and high repetition rate operation. Finally, we discuss current target supply strategies and future perspectives to establish a sustainable target provision infrastructure for advanced laser facilities.