View fulltext

View fulltext

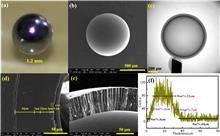

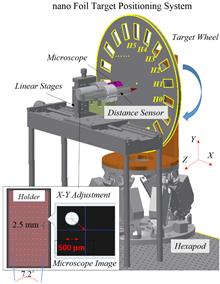

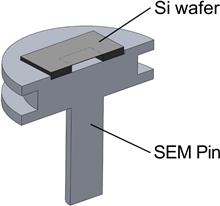

The improved laser-to-pedestal contrast ratio enabled by current high-power laser pulse cleaning techniques allows the fine features of the target survive before the main laser pulse arrives. We propose to introduce the nano-fabrication technologies into laser–plasma interaction to explore the novel effects of micro-structures. We found out that not only laser-driven particle sources but also the laser pulse itself can be manipulated by specifically designed micro-cylinder and -tube targets, respectively. The proposal was supported by full-3D particle-in-cell simulations and successful proof-of-principle experiments for the first time. We believe this would open a way to manipulate relativistic laser–plasma interaction at the micro-size level.