View fulltext

View fulltext

We report the generation of high energy 2 μm picosecond pulses from a thulium-doped fiber master oscillator power amplifier system. The all-fiber configuration was realized by a flexible large-mode area photonic crystal fiber (LMA-PCF). The amplifier output is a linearly-polarized 1.5 ns, 100 kHz pulse train with a pulse energy of up to 250 μJ. Pulse compression was achieved with (2+2)-pass chirped volume Bragg grating (CVBG) to obtain a 2.8 ps pulse width with a total pulse energy of 46 μJ. The overall system compactness was enabled by the all-fiber amplifier design and the multi-pass CVBG-based compressor. The laser output was then used to demonstrate high-speed direct-writing capability on a temperature-sensitive biomaterial to change its topography (i.e. fabricate microchannels, foams and pores). The topographical modifications of biomaterials are known to influence cell behavior and fate which is potentially useful in many cell and tissue engineering applications.

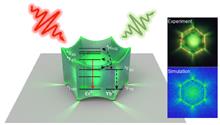

Near-infrared excited rare-earth (RE)-doped up-conversion (UC)-luminescent materials have attracted enormous attention because of their unique emission properties, such as narrow emission bands, long luminescence lifetimes, and multiple colors. However, current development of RE-doped luminescent material is hindered by weak and narrowband absorption problems and low photon-conversion quantum efficiencies. In addition to conventional approaches to enhance fluorescence intensity, controlling emission directivity to improve detection efficiency has become a promising approach to obtain higher luminescence brightnesses. In this paper, a self-suspended RE-doped UC luminescent waveguide is designed to realize directional emissions. Benefitting from the special morphology of the crown-like NaYF4:Yb3+/Er3+ microparticle, the points contact between the waveguide and substrate can be obtained to decrease energy loss. An attractive UC luminescent pattern accompanied by powerful and controllable directional emissions is observed, and the spatial emission angle and intensity distribution are explored and analyzed in detail by introducing Fourier imaging detection and simulation. This work provides a new method for achieving controllable directional fluorescence emissions and obtaining improved detection efficiency by narrowing emission directivity, which has potential applications in 3-dimensional displays and micro-optoelectronic devices, especially when fabricating self-fluorescence micron lasers.

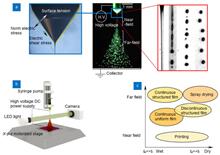

Solution processible photovoltaics (PV) are poised to play an important role in scalable manufacturing of low-cost solar cells. Electrospray is uniquely suited for fabricating PVs due to its several desirable characteristics of an ideal manufacturing process such as compatibility with roll-to-roll production processes, tunability and uniformity of droplet size, capability of operating at atmospheric pressure, and negligible material waste and nano structures. This review begins with an introduction of the fundamentals and unique properties of electrospray. We put emphasis on the evaporation time and residence time that jointly affect the deposition outcome. Then we review the efforts of electrospray printing polymer solar cells, perovskite solar cells, and dye sensitized solar cells. Collectively, these results demonstrate the advantages of electrospray for solution processed PV. Electrospray has also exhibited the capability of producing uniform films as well as nanostructured and even multiscale films. So far, the electrospray has been found to improve active layer morphology, and create devices with efficiencies comparable with that of spin-coating. Finally, we discuss challenges and research opportunities that enable electrospray to become a mainstream technique for industrial scale production.