Photonic-integrated circuits (PICs), analogous to electronic integrated circuits, have long been dreamed of and driven by the relentless desire for higher information exchange and processing capacities, allowing higher speed and bandwidth. Lithium-niobate-on-insulator (LNOI) wafer is considered as an important candidate platform for PICs, owing to its outstanding material properties featuring a broad transparency window (350 nm to 5 μm), strong linear electro-optic effect, and a large second-order nonlinearity susceptibility. A wide range of high-performance device applications, such as optical frequency convertors, high-speed Mach-Zehnder modulators, and multiplexers have been demonstrated due to the rapid developments in ion-slicing technique and LNOI nanofabrication technology. Among the various devices, optical waveguides with ultra-low propagation loss and high refractive index contrast are building elements for the realization of large-scale PICs, while optical waveguides are susceptible to sidewall roughness induced by the fabrication imperfection.

To reduce the sidewall roughness of the waveguide, diamond-blade dicing, precision cutting, focused ion beam milling, argon ion milling, and chemo-mechanical polishing (CMP) have been successively used to etch the lithium niobate (LN) thin film into waveguides with smooth sidewalls. For instance, an ultra-smooth sidewall roughness as small as 0.1 nm has been achieved (by CMP etching), leading to an ultra-low propagation loss of ridge waveguides of 2.7 dB/m (by CMP etching or argon ion milling). However, the minimum propagation loss of the waveguide determined by the intrinsic material absorption is only 0.1 dB/m. Thus, there is still room to reduce the propagation loss by improving the quality of LN thin film.

Notably, the internal crystal lattice damage induced by the ion slicing fabrication of the LNOI has long been recognized representing the ultimate limit of the Q factors achievable in the ion-slicing LNOI since 2004 by P. Günter Group, which cannot be totally recovered to the pristine bulk crystal even after high-temperature annealing at 1030οC, leading to inferior optical property of LNOI to the bulk LN crystal. Therefore, an ion-free fabrication strategy should be developed to realize LNOI waveguides with propagation loss approaching the intrinsic material absorption of LN.

Collaborated by Professor Cheng Ya, East China Normal University, and researcher Lin Jintian from Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, experimentally demonstrated such low loss LNOI waveguides by ion-free preparation of LN thin film combined with chemo-mechanical etching, together with the ability to alleviate the lattice damage and interface roughness during the ion slicing as well as the subsequent chemo-mechanical etching processes. The related results were published in Chinese Optics Letters, Volume 20, Issue 1, 2022 (Renhong Gao, et al, Lithium niobate microring with ultra-high Q factor above 108).

The LNOI microring resonators were fabricated on the LN thin film wafer with thickness above 4 μm prepared by thinning an LN bulk by crystal cutting, polishing and bonding without ion slicing and ion etching, which is carried out by Jinan NanoLN company. Then femtosecond laser direct writing and chemo-mechanical polishing (CMP) were utilized in sequence for patterning the LN thin film into microring resonators. The fabricated microring resonator possesses a thickness of only 720 nm, a diameter of 200 μm and an ultra-smooth surface.

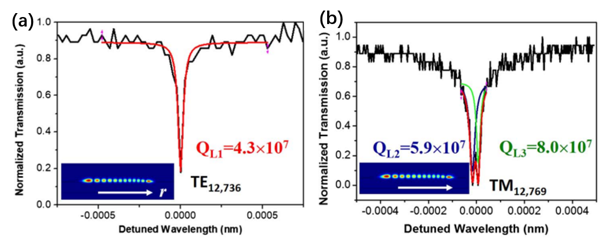

The Q factors of the microring were characterized by measuring the transmission spectrum of an LNOI ridge waveguide coupled with the microring. The highest intrinsic Q factor of the modes was measured to be 1.08×108 around 1550 nm wavelength, corresponding to waveguide propagation loss of 0.34 dB/m , as shown in Figure 1.

Fig. 1 (a) and (b) Q factors of the modes fitted by Lorentzian curves, indicating the highest intrinsic Q factor of 1.08×108, insets: the corresponding field distributions of the modes, where the direction presents the radial direction.

This ultra-high Q microring can be used as electro-optic tunable photonic devices, such as low-threshold Kerr frequency combs, narrow-linewidth Brillouin lasers, and high-brightness quantum light sources, to name a few. Such a low-loss LNOI ridge waveguide shows great potential for loss-less cascaded electro-optic modulators, high-speed information processing, and large-scale photonic integration on LNOI wafers. The ultra-high Q microrings will pave the way for integrated quantum light source, frequency comb generation, and nonlinear optical processes.